Preparation method of environment-friendly bottle cap capable of being repeatedly used

An environmentally friendly, bottle cap technology, applied in the field of new materials, can solve the problems of limited application, not many, easy water absorption, poor high and low temperature resistance, etc., and achieve the effect of improving easy water absorption, good water resistance, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

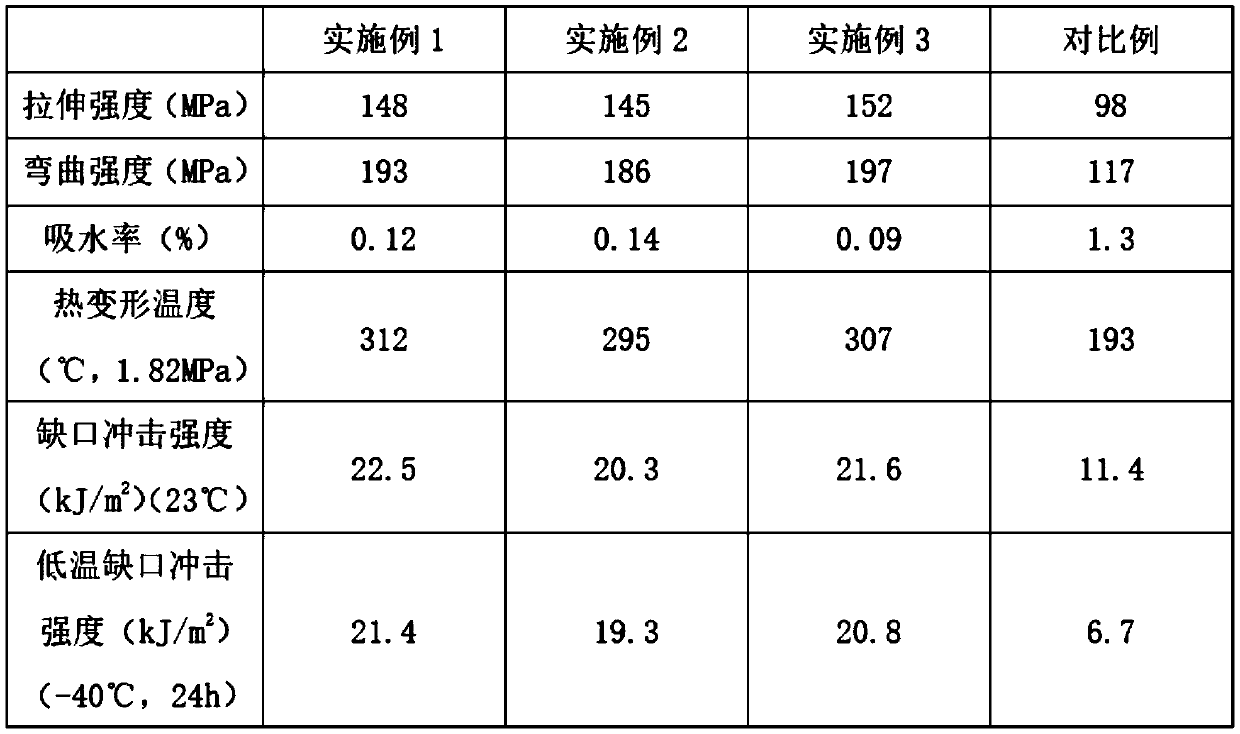

Examples

Embodiment 1

[0042] A preparation method of a reusable environment-friendly bottle cap, comprising the following steps:

[0043] Step 1, prepare the mold: prepare the corresponding mold according to the shape of the bottle cap;

[0044] Step 2, feeding: adding raw materials into the high-speed mixer, after mixing evenly, placing it in an injection molding machine to melt and plasticize to obtain a plasticized material;

[0045] Step 3, molding: adding the plasticizing material into the mold by injection molding, then adding a nucleating agent, and injection molding;

[0046] Step 4, demoulding: obtaining a reusable environment-friendly bottle cap;

[0047] Described reusable environment-friendly bottle cap, according to weight, is composed of the following raw materials:

[0048] 70 parts of modified polyamide, 12 parts of calcium stearate, 8 parts of polypropylene grafted maleic anhydride, 3 parts of nano-silicate fibers, and 3 parts of antioxidants.

[0049] The added amount of the nucl...

Embodiment 2

[0075] A preparation method of a reusable environment-friendly bottle cap, comprising the following steps:

[0076] Step 1, prepare the mold: prepare the corresponding mold according to the shape of the bottle cap;

[0077] Step 2, feeding: adding raw materials into the high-speed mixer, after mixing evenly, placing it in an injection molding machine to melt and plasticize to obtain a plasticized material;

[0078] Step 3, molding: adding the plasticizing material into the mold by injection molding, then adding a nucleating agent, and injection molding;

[0079] Step 4, demoulding: obtaining a reusable environment-friendly bottle cap;

[0080] Described reusable environment-friendly bottle cap, according to weight, is composed of the following raw materials:

[0081] 60 parts of modified polyamide, 10 parts of calcium stearate, 5 parts of polypropylene grafted maleic anhydride, 2 parts of nano-silicate fiber, and 1 part of antioxidant.

[0082] The added amount of the nucle...

Embodiment 3

[0108] A preparation method of a reusable environment-friendly bottle cap, comprising the following steps:

[0109] Step 1, prepare the mold: prepare the corresponding mold according to the shape of the bottle cap;

[0110] Step 2, feeding: adding raw materials into the high-speed mixer, after mixing evenly, placing it in an injection molding machine to melt and plasticize to obtain a plasticized material;

[0111] Step 3, molding: adding the plasticizing material into the mold by injection molding, then adding a nucleating agent, and injection molding;

[0112] Step 4, demoulding: obtaining a reusable environment-friendly bottle cap;

[0113] Described reusable environment-friendly bottle cap, according to weight, is composed of the following raw materials:

[0114] 80 parts of modified polyamide, 15 parts of calcium stearate, 10 parts of polypropylene grafted maleic anhydride, 5 parts of nano-silicate fibers, and 5 parts of antioxidants.

[0115] The added amount of the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal deformation | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com