Rail vibration reduction ballast bed device

A track and track bed technology, applied in the field of track vibration reduction, can solve problems such as increasing maintenance costs, potential safety hazards, aggravating vibration and noise impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

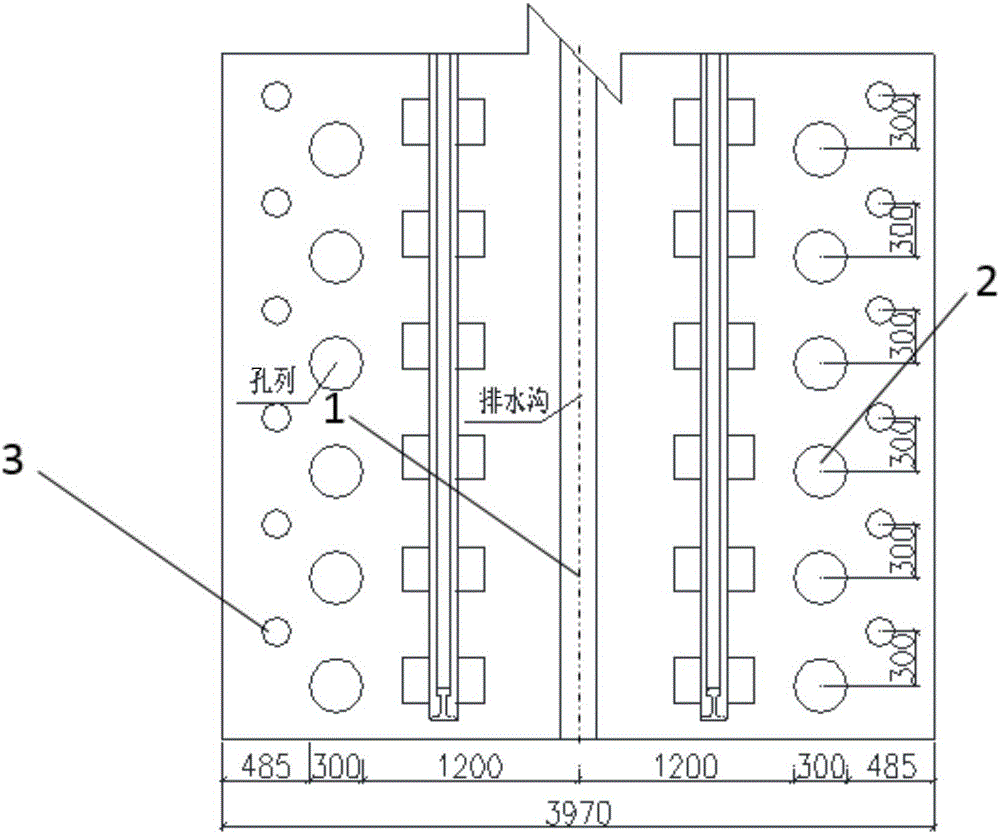

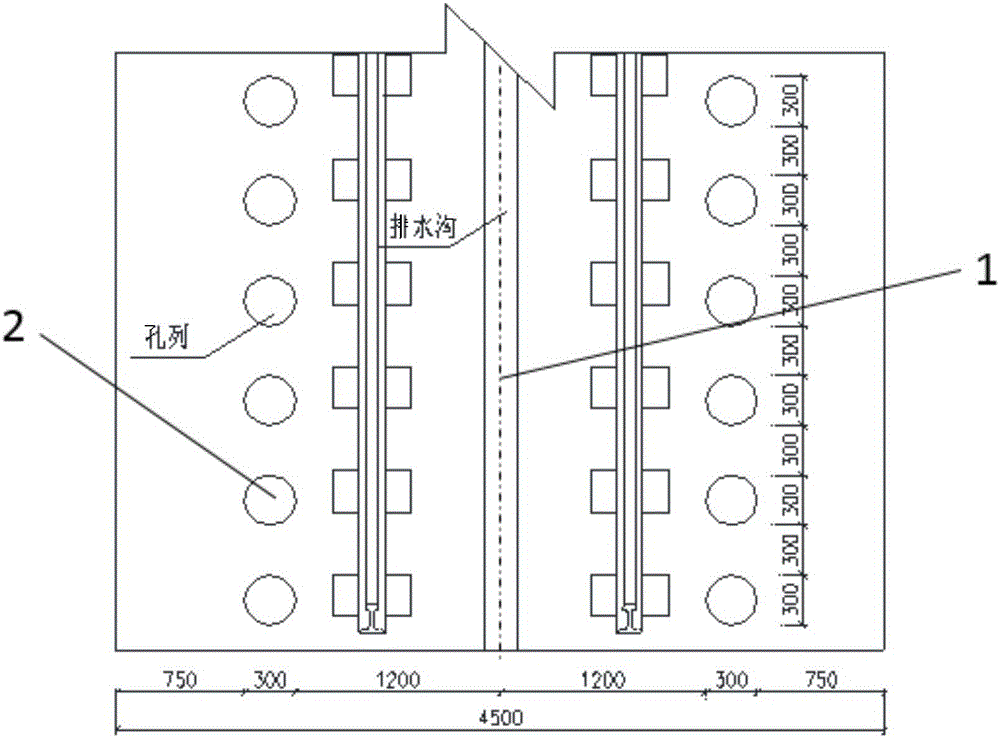

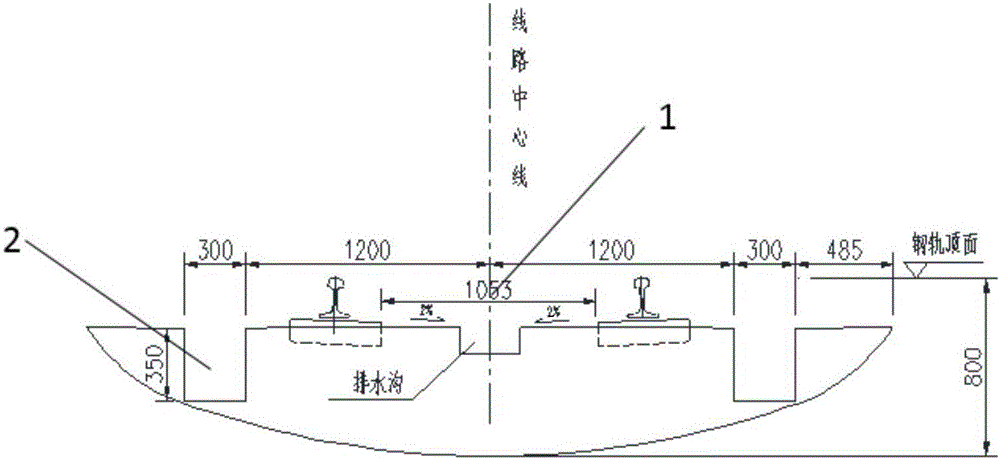

[0041] The specific embodiment is as follows: the hole row (2) is set outside the set distance of the center line (1) of the track bed line by a punching machine, and the set distance can be 1200mm. The radius r of each cell in the hole row is kept within the range of 8-15mm, the minimum depth is 15mm, and the maximum can reach the edge of the tunnel structure. This type can be applied to various types of tunnels, including tunnels constructed by mining method, tunnels constructed by shield method, and tunnels constructed by open-cut method, etc.

[0042] 2. Anti-vibration ballast bed for double rows of holes

[0043] The cross-sectional layout diagram of the double-row hole track bed under the cross-section of a horseshoe-shaped tunnel provided by the embodiment of the present invention is as follows: Figure 9 shown, Figure 10 The plane layout diagram of the double-row hole track bed under the cross-section of a horseshoe-shaped tunnel provided for the embodiment of the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap