Self-adaptive power vibration reduction gear

A dynamic vibration reduction and self-adaptive technology, applied in belts/chains/gears, components with teeth, transmission parts, etc., can solve the problem that gears cannot increase the frequency of vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

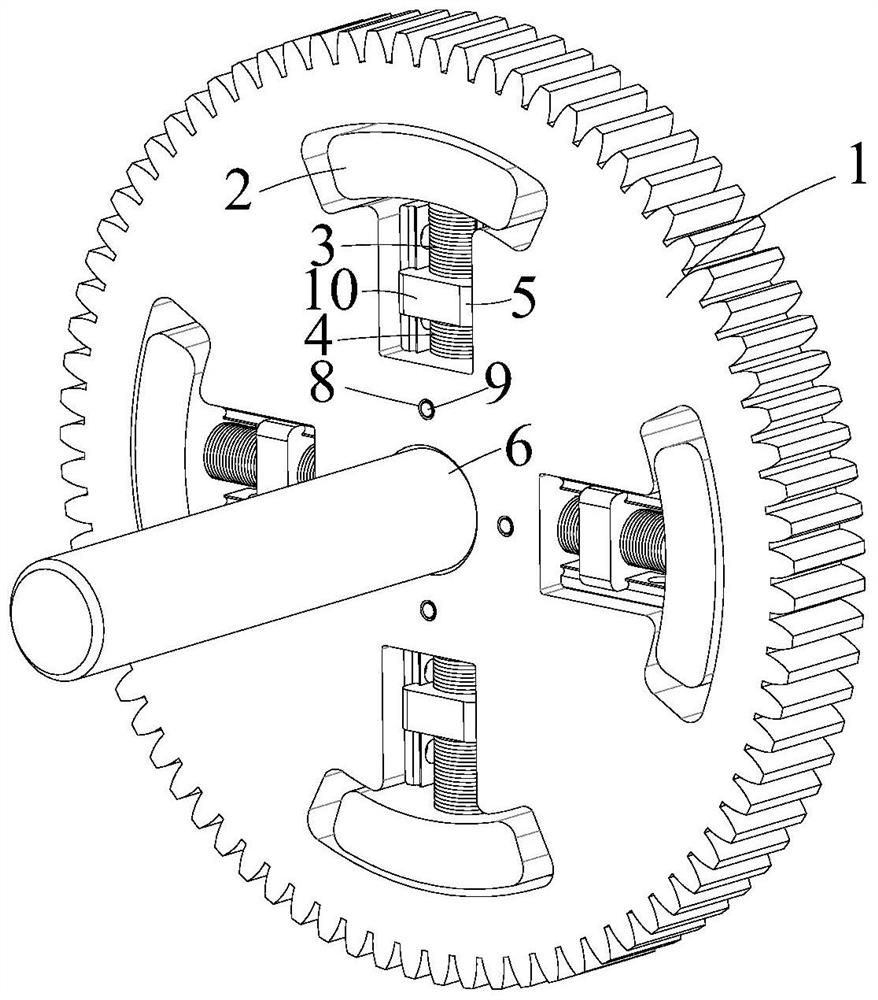

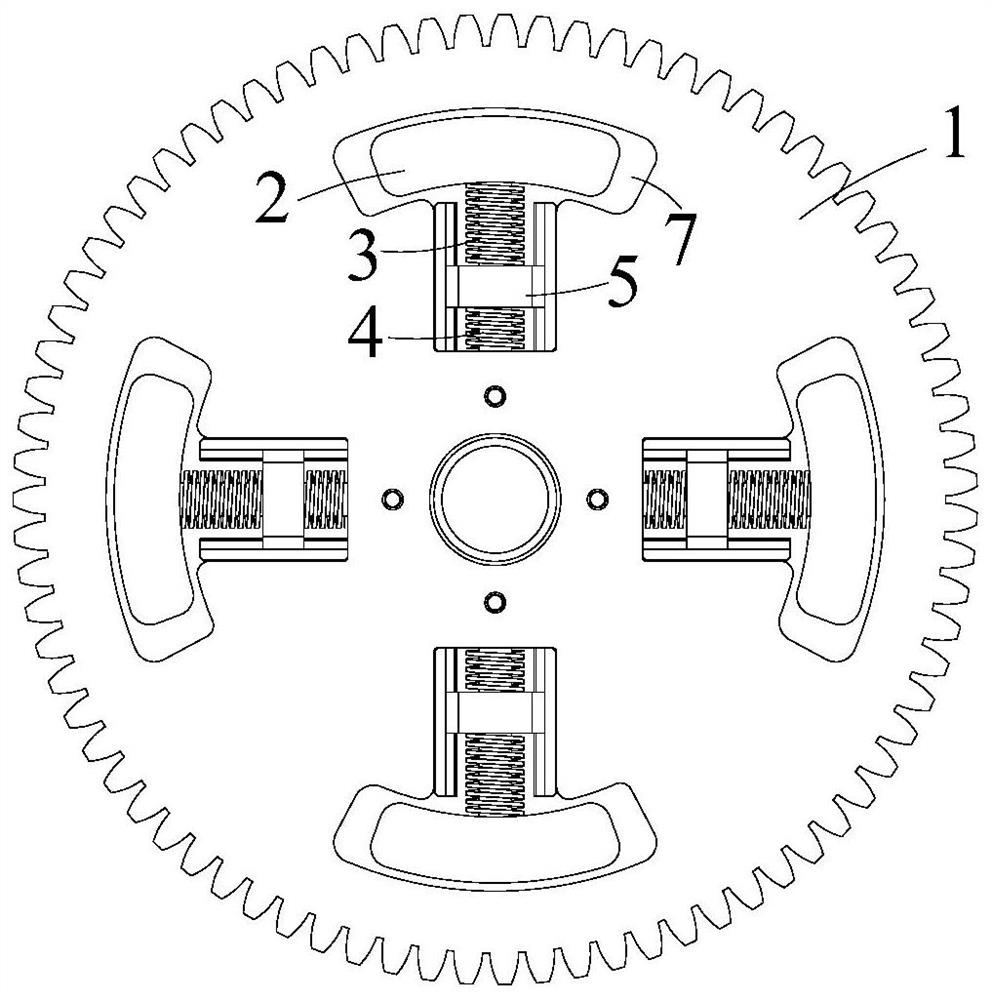

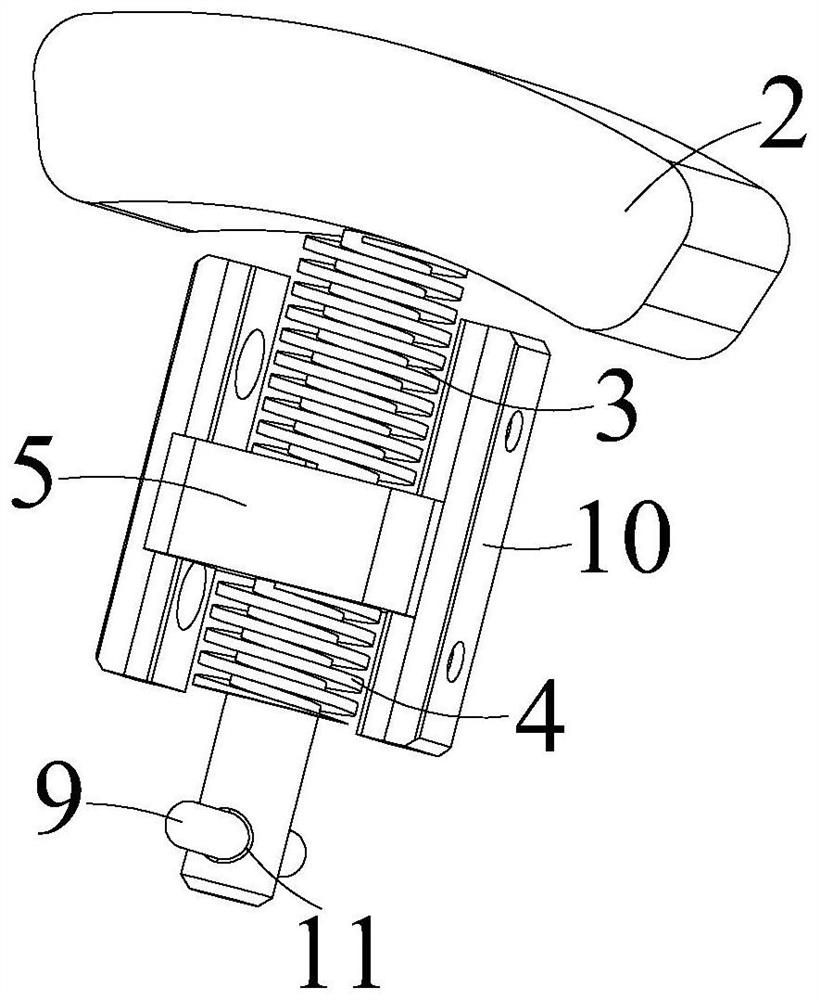

[0017] An adaptive dynamic damping gear, including a gear 1, the gear 1 is embedded with several damping modules, and the damping modules include a damping mass 2, an centrifugal mass 5, an upper spring 3 and a lower spring 4 , the gear 1 is provided with a mounting groove 7, the vibration-damping mass 2 is fixed in the mounting groove 7, a connecting rod is fixed on one side of the vibration-damping mass 2, and the other end of the connecting rod Fixed in the installation groove 7, the centrifugal mass 5 slides on the connecting rod, the upper spring 3 and the lower spring 4 are respectively provided on both sides of the centrifugal mass 5, and the upper spring 3 and the lower spring 4 are both sleeved on the connecting rod, one end of the upper spring 3 is against the damping mass 2, the other end is against the centrifugal mass 5, and one end of the lower spring 4 is against the centrifugal mass 5. The other end of the mass block 5 is against the bottom of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com