Super large super deep basement ground pit construction method

A construction method and basement technology, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as the inapplicability of foundation pits in super-large and super-deep basements, and achieve the effects of solving construction safety problems, increasing utilization rates, and reducing total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

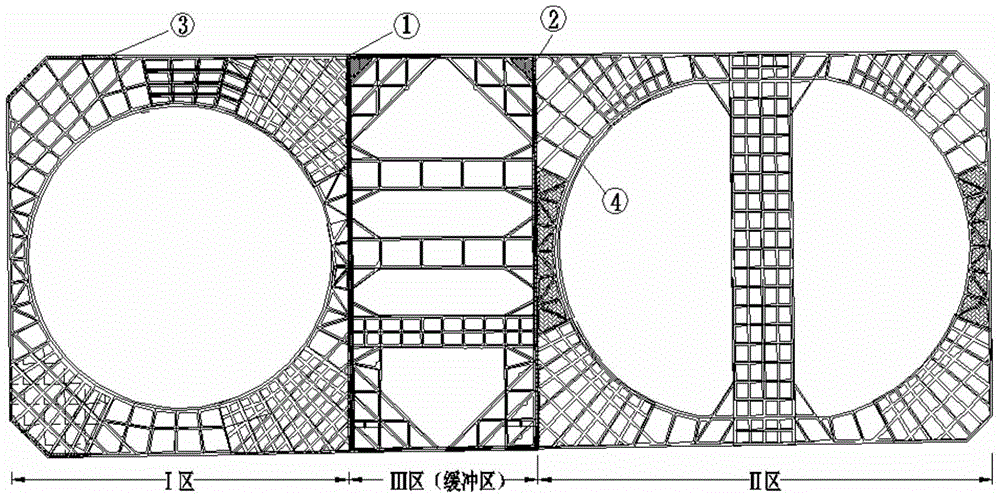

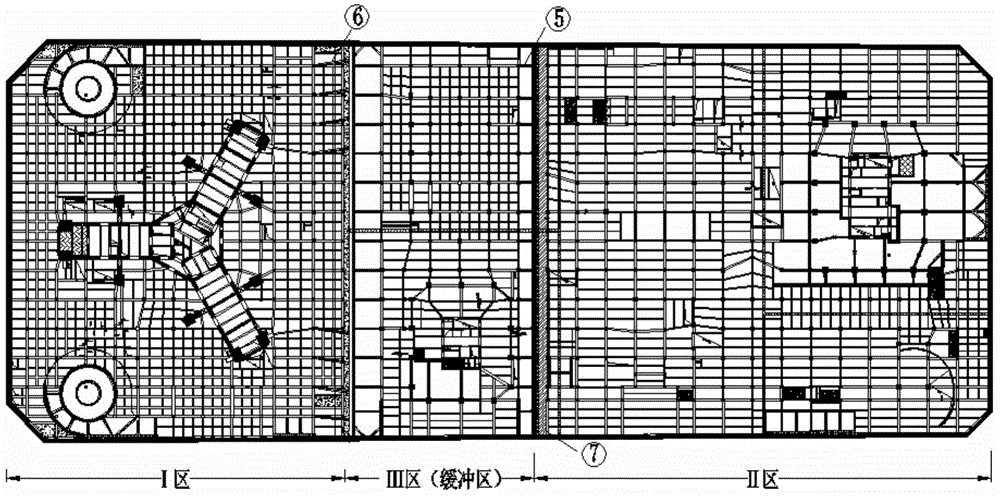

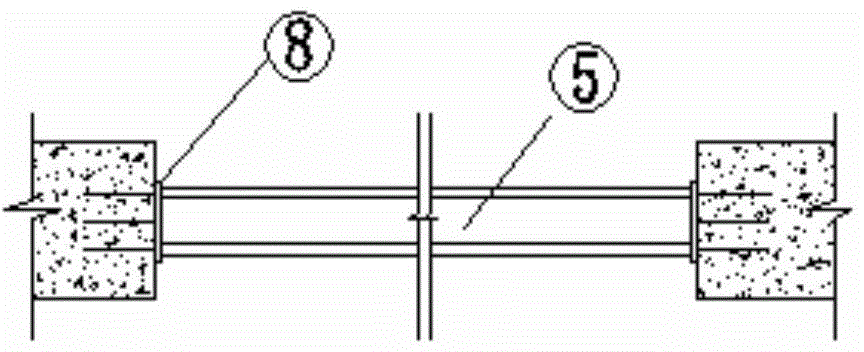

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a partition construction method of super large and super deep basement pit is characterized in that it is carried out according to the following steps:

[0018] Step (1) Set up a "two walls in one" underground diaphragm wall 3 around the foundation pit of the super-large and deep basement as the foundation pit enclosure, and set a temporary connecting wall 1 and bored pile row 2 in the foundation pit to integrate the whole It is divided into three parts, and the two sides are subdivided for construction at the same time, and the middle area is used as a buffer zone for construction;

[0019] Step (2) Set ring support 4 during the excavation of the foundation pit on both sides, that is, zone I and zone II, and transmit the horizontal force around the foundation pit to the buffer zone, zone III, through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com