Cofferdam launching method

A technology of cofferdams and water pipes, applied in construction, infrastructure engineering, caissons, etc., can solve the problems of unfavorable bracket recovery, difficulty in salvaging brackets, and high water depth requirements at water inlets, so as to reduce water depth requirements, reduce depth, and facilitate The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] An embodiment of the present invention provides a method for launching a cofferdam, comprising the following steps:

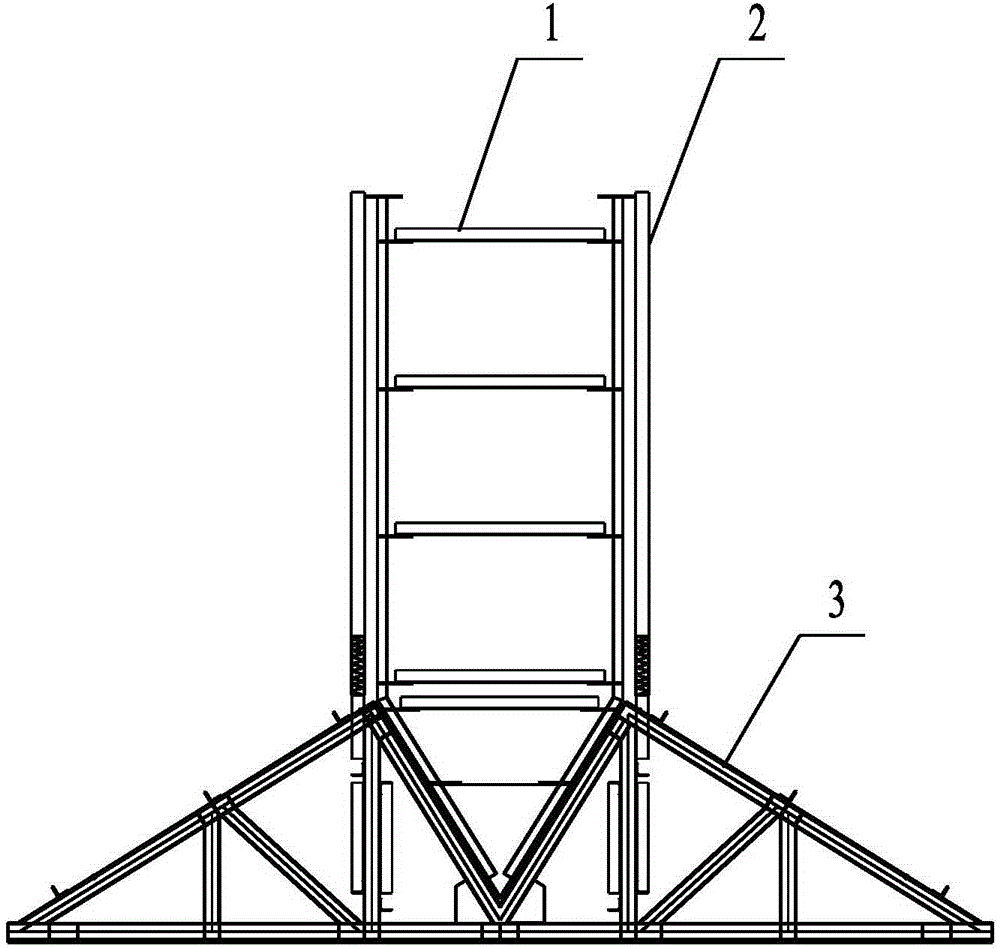

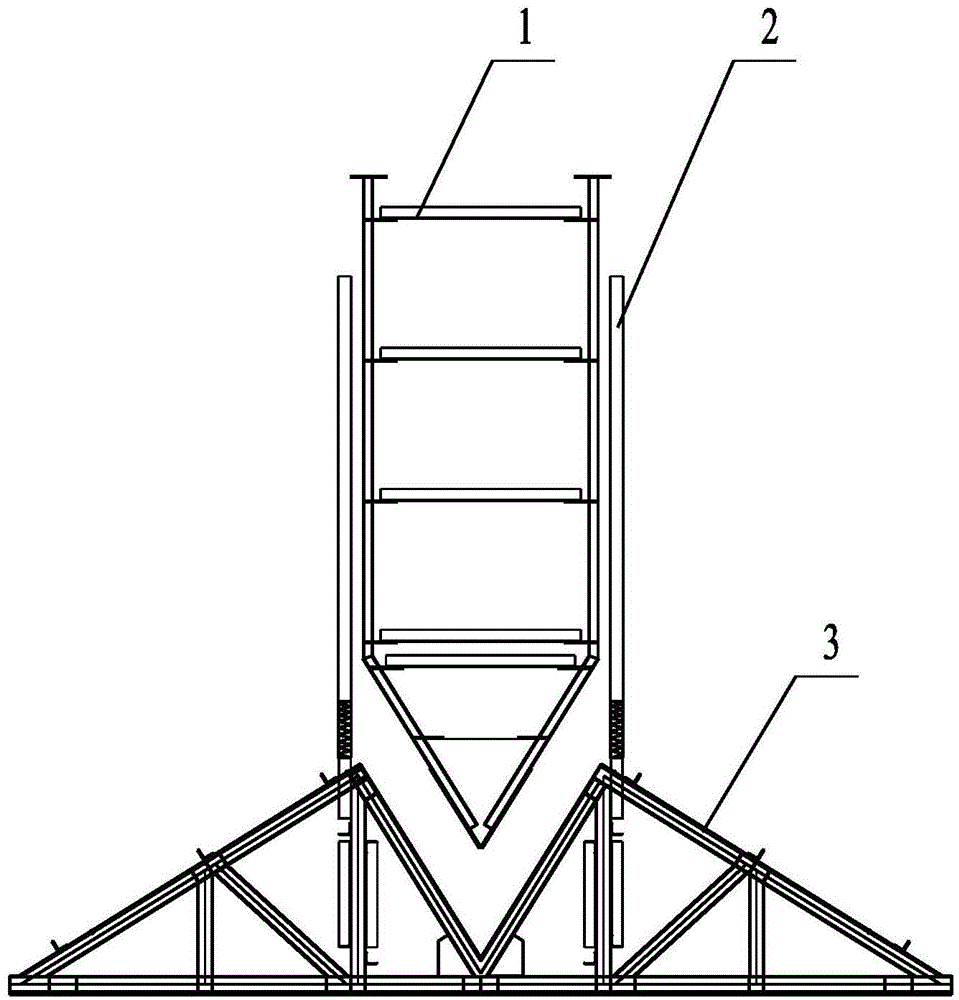

[0030] A, arrange the launching site of the cofferdam 1, arrange the air bag and the anchorage on the launching site, arrange the buoyancy box 3 on the air bag, the buoyant box 3 includes several segments, each segment is provided with a water pipe 2, and the buoyant tank 3 Assemble the cofferdam 1, connect the cofferdam 1 to the anchorage through cables, inflate the airbag after the cofferdam 1 is assembled, lift the cofferdam 1, and go to step B.

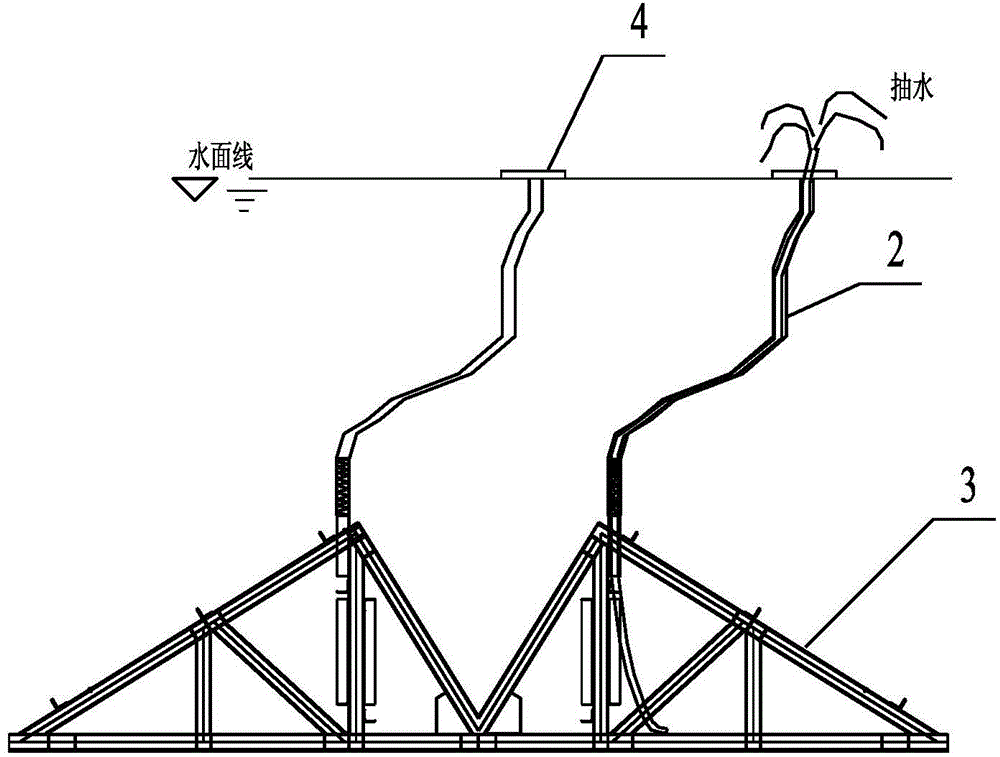

[0031] B. see figure 1 As shown, cut the cables between the cofferdam 1 and the anchorage, so that the cofferdam 1 and the buoyancy tank 3 are launched into the water at the same time; see figure 2 As shown, after both the cofferdam 1 and the buoyancy tank 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com