Ventilating waterproof structure of prefabricated cabin

A breathable, waterproof, prefabricated cabin technology, applied in roof drainage, building structure, roof insulation materials, etc., can solve the problems that cannot meet the requirements of breathable and waterproof, and achieve the effect of simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

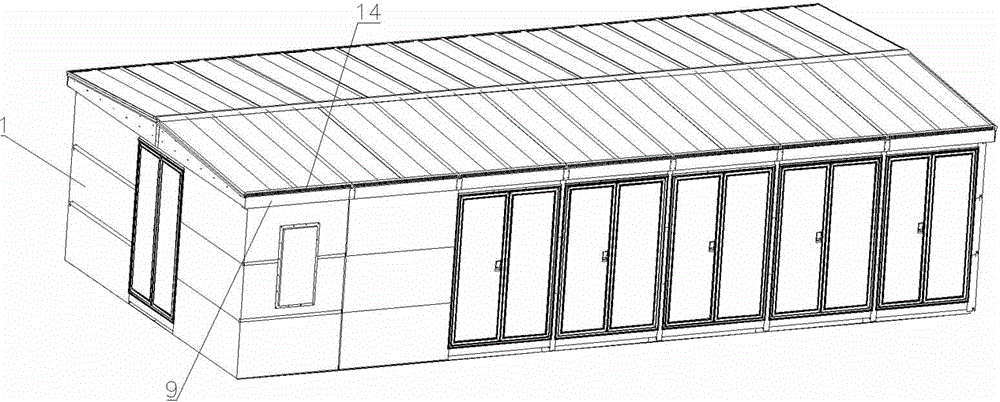

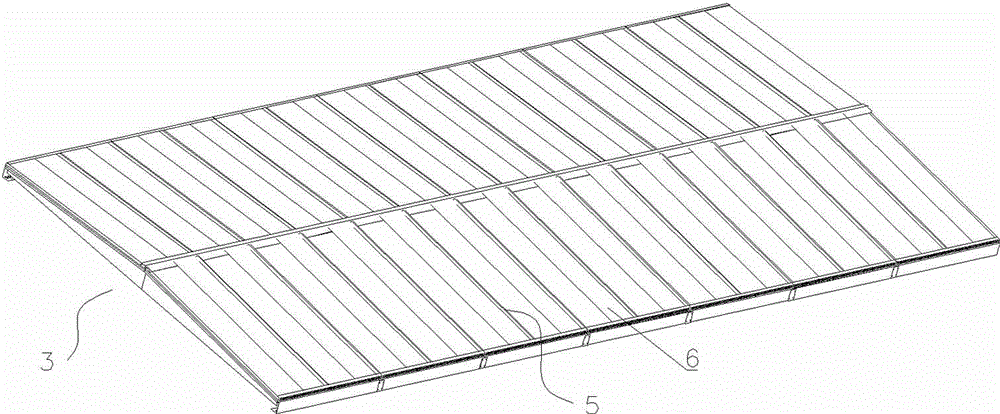

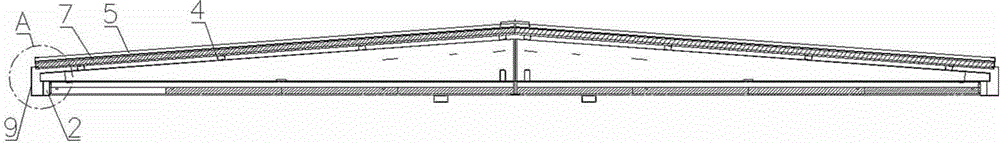

[0025] An embodiment of the air-permeable and waterproof structure of the prefabricated cabin in the present invention is as Figure 1~Figure 7 As shown, it includes a cabin body 1 , a top cover 3 arranged on the top of the cabin body 1 , and a breathable and waterproof member 9 connected between the cabin body 1 and the top cover 3 . Wherein the cabin body 1 includes a cabin body frame, a sealing plate and a door panel, and the cabin body frame includes a welded base, a column and a top frame 2, and the top frame 2 is made of square steel. The top cover 3 includes a herringbone roof frame and a top plate 5. The herringbone roof frame constitutes a skeleton 4, which is assembled by welding a number of herringbone beams arranged along the width direction of the cabin body 1 and a number of transverse bearing brackets of different cross-sections. 5 is welded on the top of the frame 4, and is formed by splicing together several top plate panels 6, so that the top surface of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com