An indoor test method for monitoring the difference in fluid production capacity between layers

An indoor test and capability technology, applied in the fields of earthwork drilling, wellbore/well components, etc., can solve problems such as the inability to realize indoor monitoring, and achieve the effect of enriching monitoring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

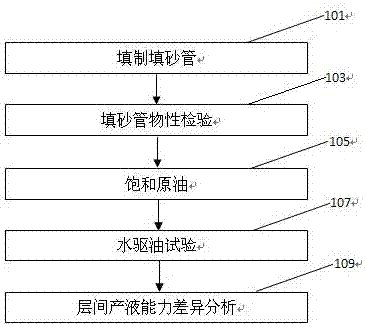

[0024] Such as figure 1 as shown, figure 1 It is a flowchart of a specific embodiment of the indoor test method for monitoring the difference in liquid production capacity between layers of the present invention.

[0025] In step 101, the sand filling pipe is filled. According to the porosity and permeability of each layer in the test block, the type of filling, pressing pressure and pressing time are determined, and the sand filling pipe with the physical properties of the simulated reservoir is filled. In one embodiment, according to the porosity and permeability of each layer with the same vertical thickness in the test simulation block A reservoir (see Table 1), three Φ2.5cm×100cm sand fillings with different permeability are filled with qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com