Magnetic bearing, shaft and shaft mounting

A technology of magnetic bearings and permanent magnets, applied in shafts and bearings, magnetic bearings, bearings, etc., can solve problems such as large tolerance movement, and achieve the effects of small current heat loss, uniform flux density distribution, and minimized eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

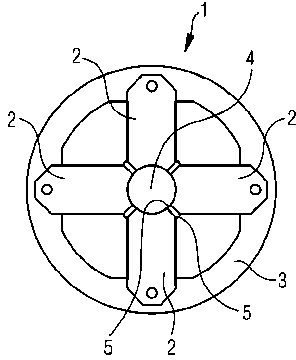

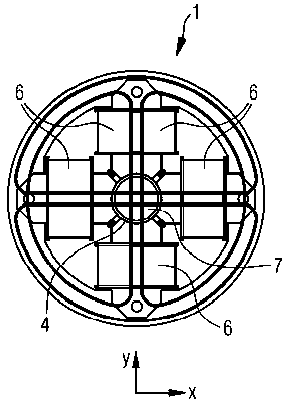

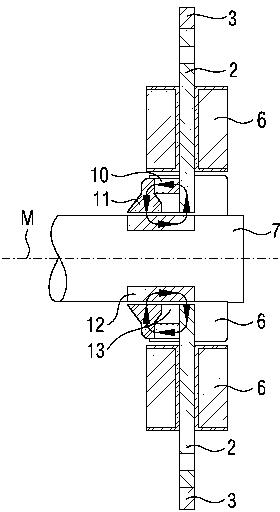

[0049] exist figure 1 A stator 1 is shown in , which has four pole cores 2 which are connected to each other as a stator cross structure. Arranged at the outer end of the pole core 2 is a stator ring 3 which surrounds all the pole cores 2 . At the other end of the pole core 2 there is provided an opening 4 which can receive a shaft (not shown here). The pole cores 2 are connected to one another at their inner ends by means of saturated webs 5 . The first saturated web 5 is arranged in the vicinity of the opening 4 , while the second saturated web 5 is arranged at a greater distance from the opening 4 . In each case two saturation bridges 5 connect two adjacent pole cores 2 . The saturating webs 5 are designed in such a way that the coil flux essentially does not flow through the saturating webs 5 or adjacent pole cores arranged therebetween, but instead flows through the shaft which is then arranged in the opening 4 . The pre-magnetizing flux through the permanent magnet w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com