Automatic height adjustment valve for optical vibration isolation platform

A vibration isolation platform and automatic adjustment technology, applied in multi-way valves, valve devices, shock absorbers, etc., can solve the problems of low vibration isolation response accuracy, poor sealing performance, and low height reset sensitivity of vibration isolators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention will be further described.

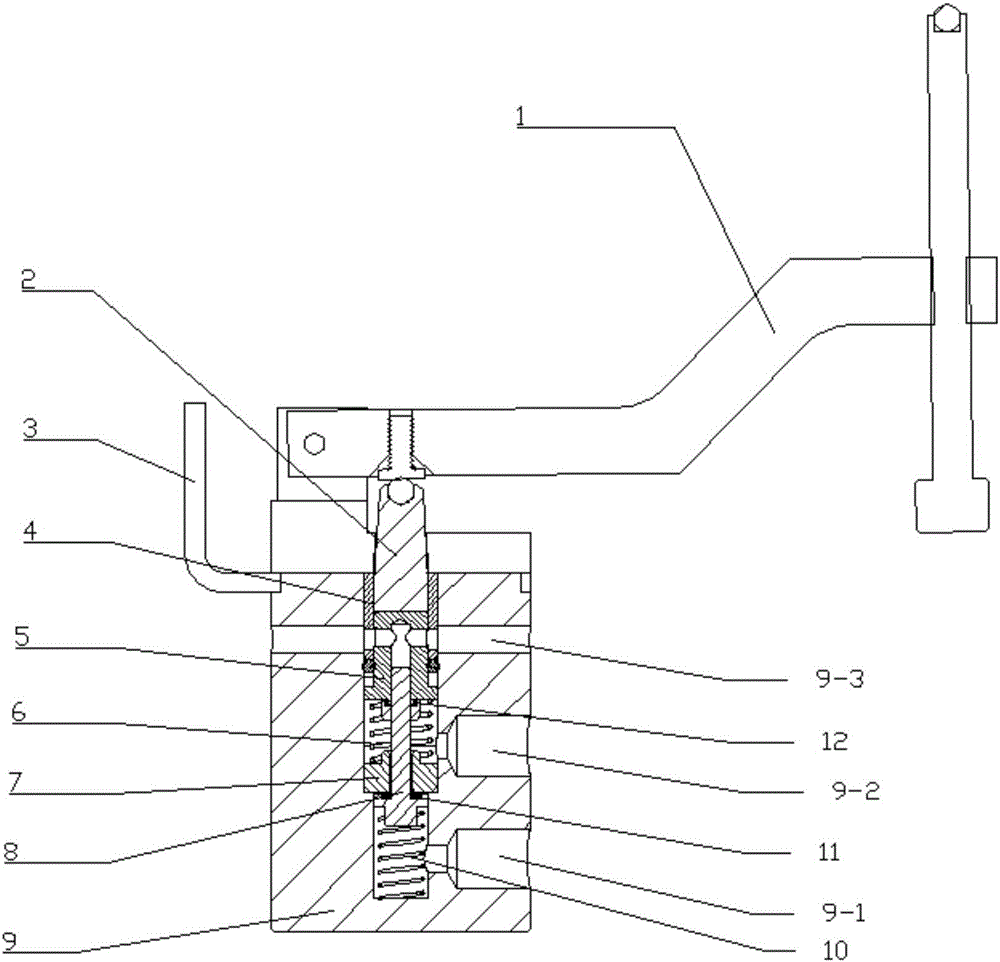

[0021] see first figure 2 , figure 2 It is a structural schematic diagram of the automatic height adjustment valve of the optical vibration isolation platform of the present invention

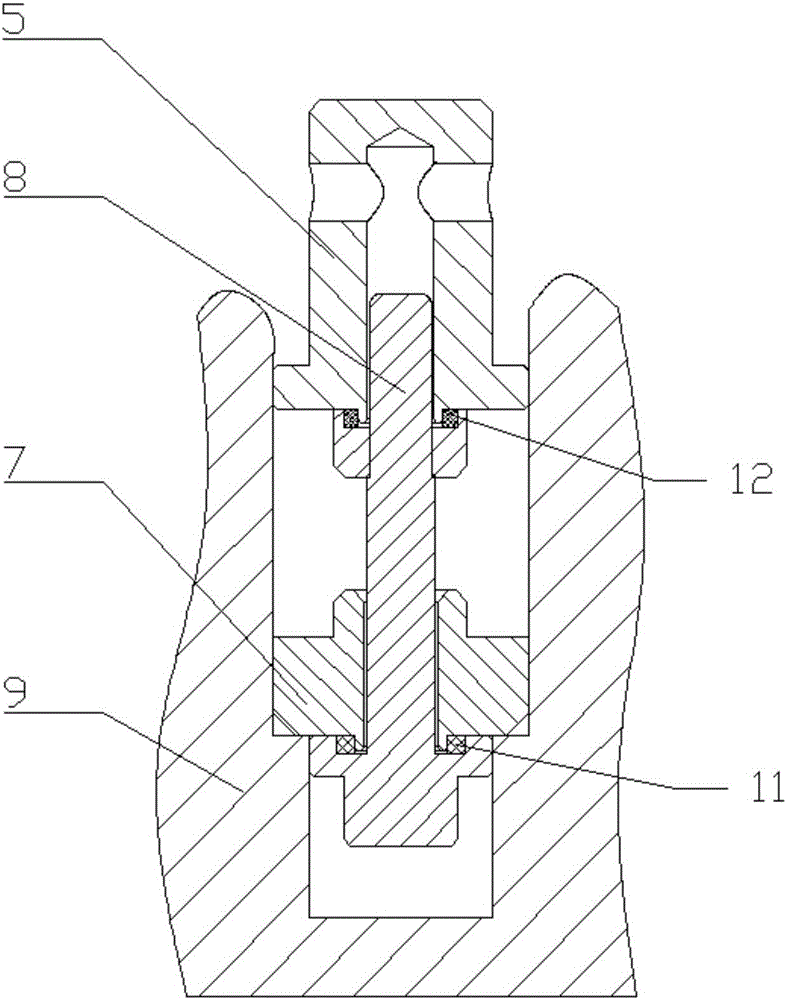

[0022] An automatic height adjustment valve for an optical vibration isolation platform, including a lever plate 1, a thimble 2, a hinge seat 3, an insert sleeve 4, an upper steel sleeve 5, a lower steel sleeve 7, a valve core 8, a valve body 9, and a first compression spring 6 , the first thin sealing ring 12, the second compression spring 10 and the second thin sealing ring 11, the inner cavity of the valve body 9 is composed of a lower vertical cavity with a smaller diameter and a larger upper circular cavity with a larger diameter. cavity, the lower circular cavity has an air inlet 9-1, the upper circular cavity has an air discharge port 9-2 and an air outlet 9-3, and the valve core 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com