Multicomponent glass up-conversion white light optical fiber lighting device

A fiber optic lighting, multi-component technology, applied in lighting devices, lighting device parts, lighting and heating equipment, etc., can solve the problems of reduced light scattering and uneven light emission of optical fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and beneficial results of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments and with reference to the accompanying drawings, but the protection scope of the present invention is not limited. Furthermore, while the present invention provides illustrations containing particular values for certain parameters, it should be understood that these parameters need not be exactly equal to the respective values, but rather approximately equal to the respective values within certain error margins or design constraints.

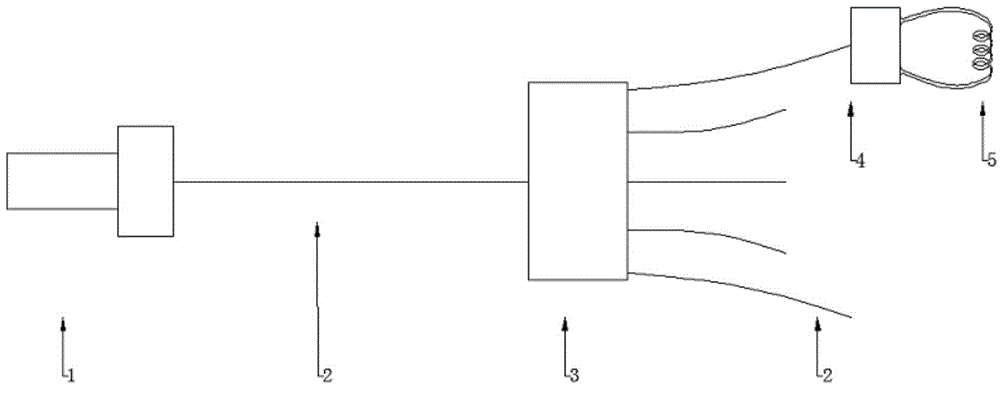

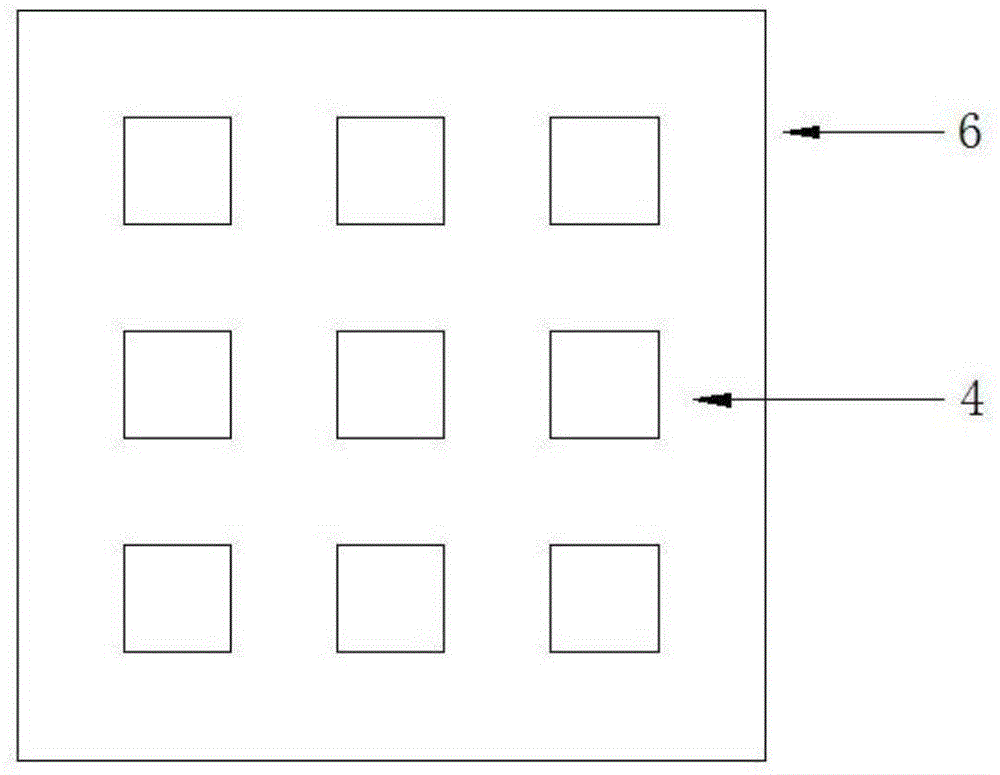

[0027] The invention provides a multi-component glass up-conversion white light optical fiber lighting device, such as figure 1 As shown, the device includes a 980nm laser 1 for providing pump light and its transmission fiber 2 , a fiber optic splitter 3 , a 3dB power splitter 4 and a helically wound multi-component glass up-conversion lum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com