Shell-and-tube heat exchanger

A kind of shell and tube heat exchanger, heat exchange tube technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

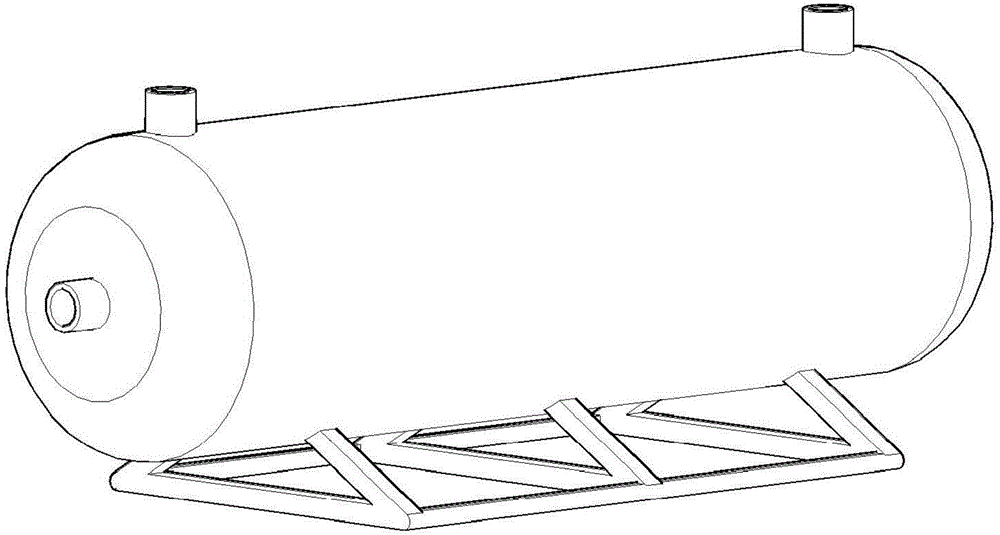

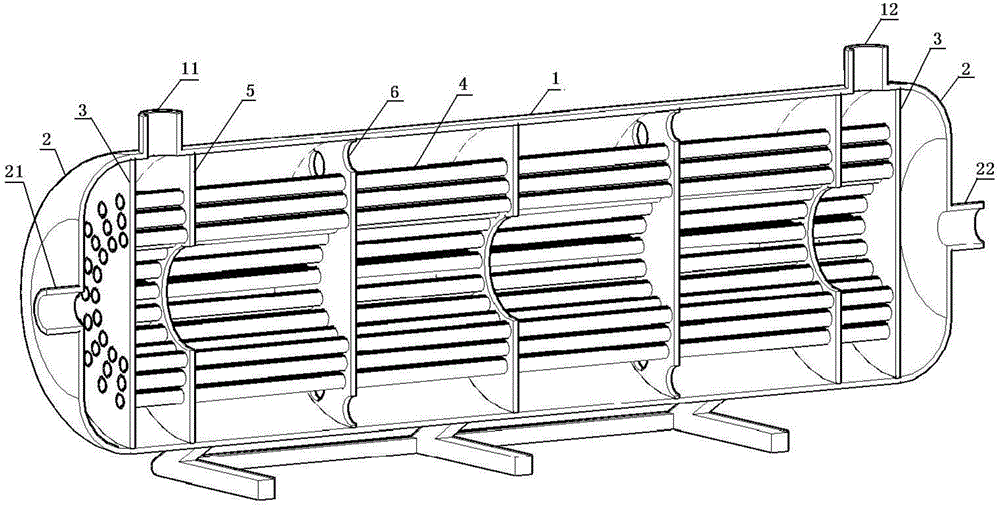

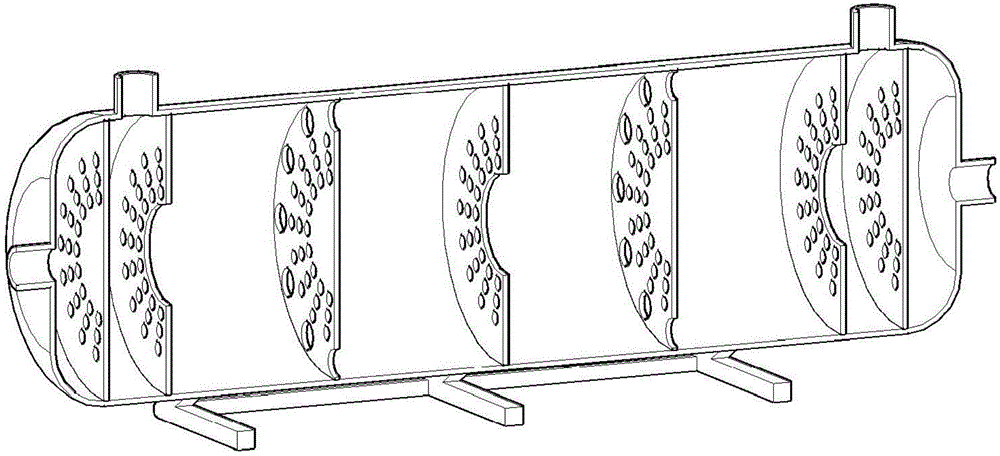

[0027] Such as figure 1 and figure 2 As shown, the shell and tube heat exchanger mainly consists of a shell 1, a tube box 2 located on both sides of the shell 1, a tube plate 3 between the tube box and the shell, and a heat exchange tube 4 placed in the shell composition. A saddle is provided under the casing to fix the shell-and-tube heat exchanger on the ground or other equipment. The housing is generally cylindrical.

[0028] A shell-side fluid inlet 11 is provided on the outer wall of the shell near one end edge of the shell, and a shell-side fluid outlet 12 is provided on the outer wall of the shell near the other end edge of the shell. The interstitial flow exits through the shell-side fluid outlet.

[0029] The tube box at one end of the shell side fluid inlet is provided with a tube side fluid inlet 21, and the other tube box is provided with a tube side fluid outlet 22; On the plate, the openings at both ends of the heat exchange tubes are respectively located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com