Temperature Compensation Boiler Drum Level Gauge

A boiler steam drum and temperature compensation technology, which is applied in the direction of displaying the liquid level indicator through pressure measurement, which can solve the problems of output signal change and inaccurate liquid level data, and achieve the effect of changing the phenomenon of pressure change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

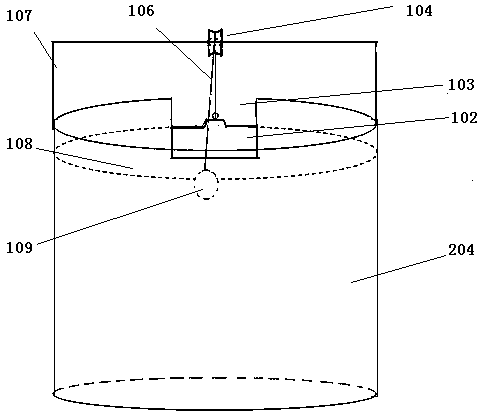

[0017] The following reference figure 1 In the figure, 101: reference cup, 102: gate, 103: notch, 104: fixed pulley, 106: rope body, 107: support frame, 108: liquid level, 109: floating body.

[0018] In this invention, a notch 103 is provided on the wall of the condensed water reference cup 101. The notch 103 is provided with a gate 102 that slides up and down along the notch 103. A floating body 109 is provided in the reference cup 101. The gate 102 utilizes a rope 106 is connected with the floating body 109 through the fixed pulley 104, and the fixed pulley is arranged on the support frame 107. The rise or fall of the floating body 109 drives the gate 102 to fall or rise to adjust the liquid level of the reference cup 101, and the condensed water reference cup wall 101 There may also be two gaps on the top, and the two gaps are respectively provided with gates 102 that slide up and down along the gaps. The gates 102 are connected to the floating body through a fixed pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com