Processing method and processing apparatus for fresh-cut Zhejiang fritillaria bulb decoction pieces

The technology of a processing method and processing device is applied in the field of processing method and processing device of fresh-cut Fritillaria decoction pieces, which can solve the problems of uneven thickness of slices, low production efficiency, high labor intensity, etc., to reduce the loss of active ingredients, slice Uniform thickness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of processing method of fresh-cut Fritillaria decoction pieces comprises the following steps successively:

[0031] A: Wash fresh Fritillaria;

[0032] B: Sliced fresh fritillary;

[0033] C: Put the slices into an oven for drying.

[0034] The slice thickness of the fresh Fritillaria slices is 2-6mm, and the slice thickness is 4mm in the present embodiment. The temperature of the oven during the drying process is 60-80° C., and the temperature of the oven during the drying process in this embodiment is 60° C. The drying time is 5-7 hours, and the drying time in this embodiment is 6 hours.

[0035] It is proved by experiments that the processing method of Fritillaria in this example can preserve the active ingredients (Piimin A, Peiminin B) and extracts to the greatest extent.

Embodiment 2

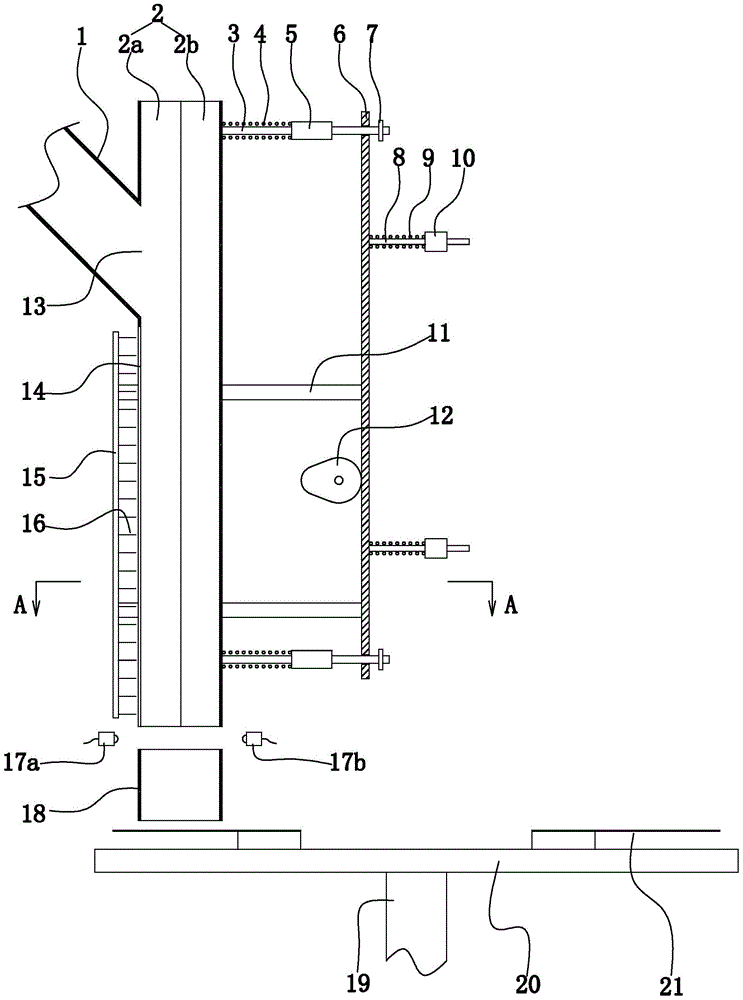

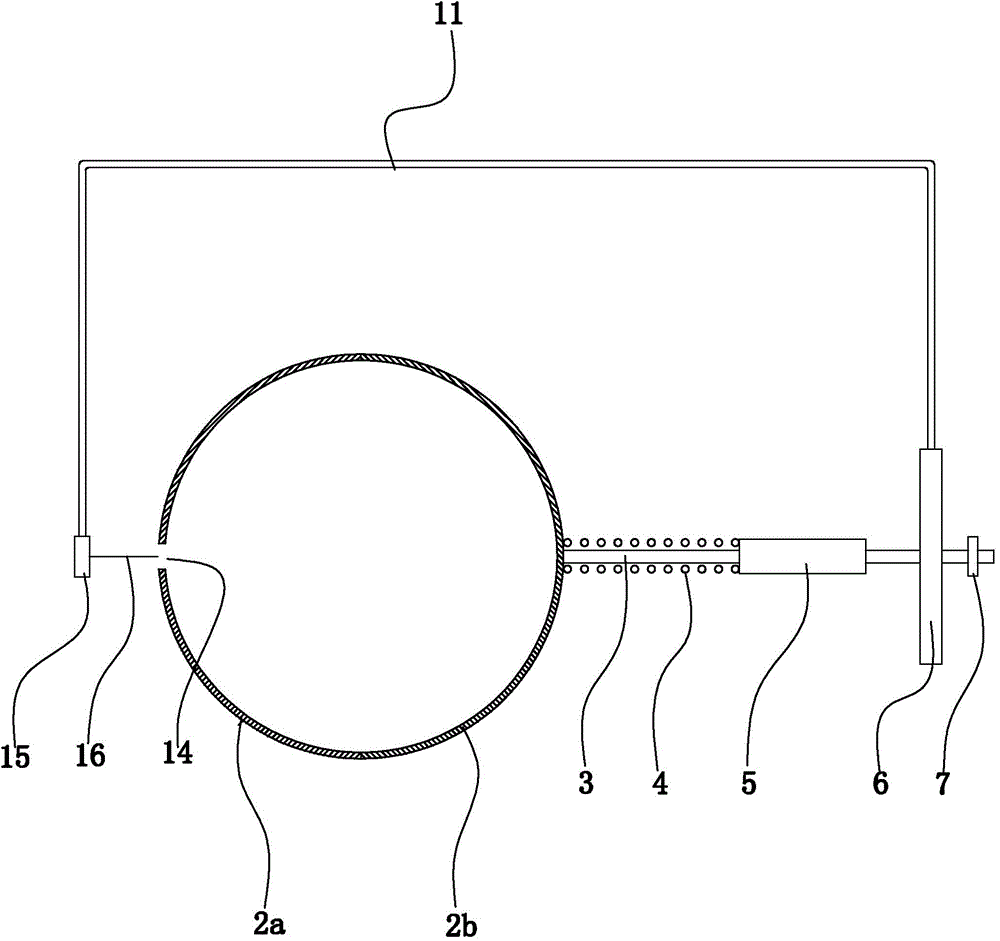

[0036] Embodiment 2: as figure 1 As shown, a processing device for freshly cutting Fritillaria decoction pieces includes a frame, a cutter head 20 that is rotatably arranged on the frame through a vertical rotating shaft 19, and two cutting blades 21 that are symmetrically arranged on the upper surface of the cutter head. The frame is used to rotate the rotary actuator of the cutter head, the vertical feeding pipe 2 arranged on the frame, the vertical limit sleeve 18, the feeding pipe 1 extending obliquely downwards and the anti-blocking device. The cutter head is set horizontally. The cutting blade is set horizontally. The distance between the cutter disc and the cutting blade is 2-6mm. The rotary actuator includes a drive motor for driving the vertical shaft to rotate.

[0037] The vertical feeding pipe and the vertical limit sleeve are round pipes. The lower end of the vertical feed pipe is open. The vertical limit sleeve is fixed on the frame. The vertical feeding pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com