Automatic water blowing device

An automatic, plate-mounted technology, used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as inability to dry workpieces, waste of energy, and high noise, achieve high-efficiency drying, reduce energy consumption, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

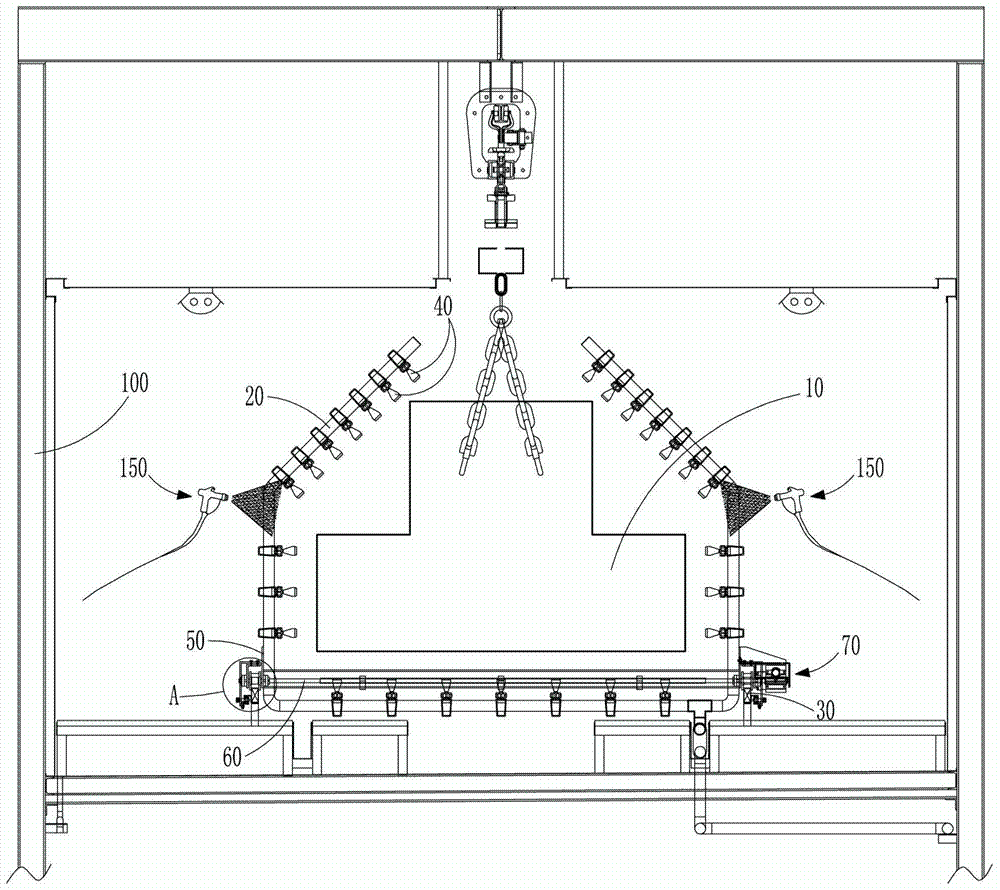

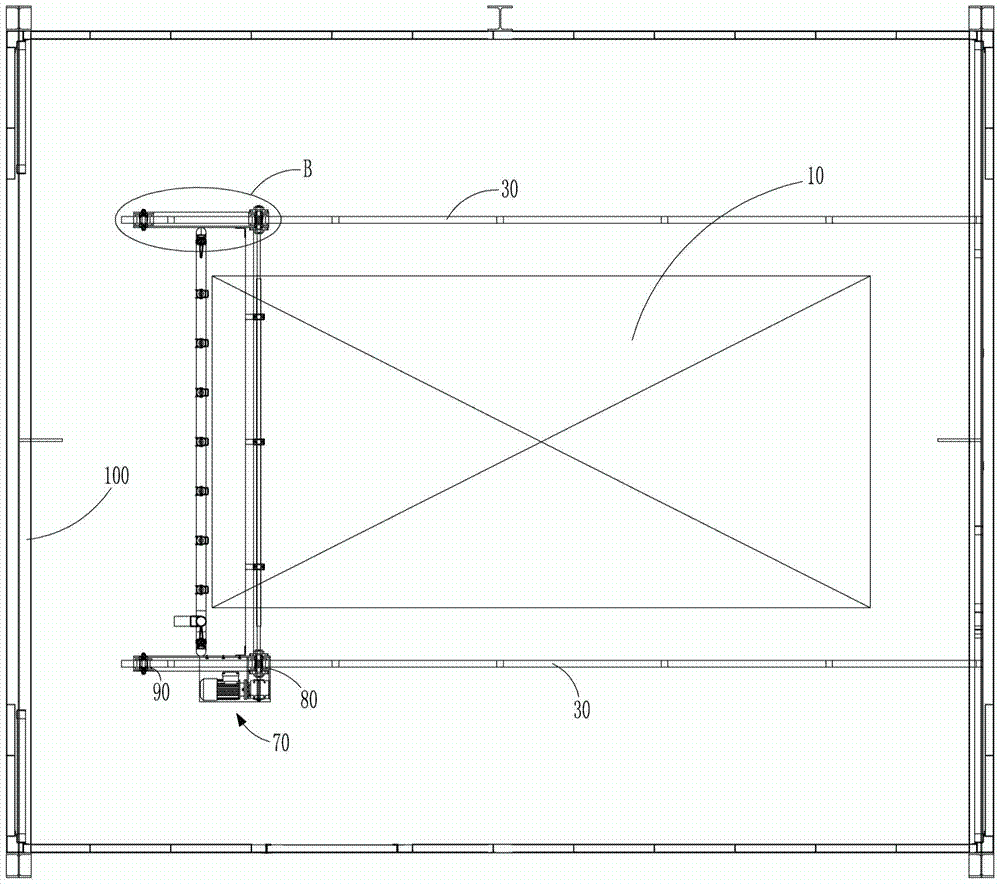

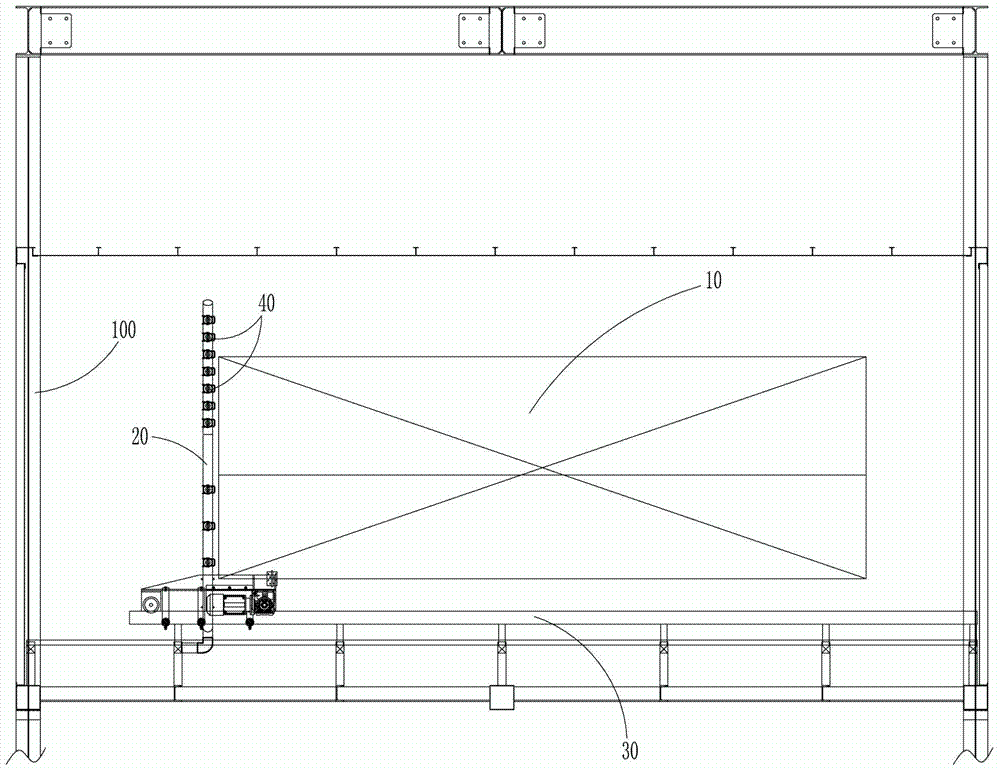

[0018] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0019] as attached figure 1 to attach image 3 As shown, an automatic water blowing device of the present embodiment is used to dry the residual water on the surface of the workpiece 10 after cleaning, and it includes a support frame 20 extending approximately along the periphery of the longitudinal section of the workpiece 10, a support frame 20, a pair of rails 30 that move, and a drive mechanism that drives the support frame 20 to move along the rails 30. The support frame 20 is provided with several air outlet blow nozzles 40 pointing to the workpiece 10 along its extension direction, and the air outlet blow nozzles 40 are connected to the air source. , in this embodiment, the support frame 20 is a hollow pipe structure, the support frame 20 is connected to the air source through a three-way joint and a hose, and through the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com