Method for manufacturing bimetallic seamless plastic insert casting piece

A production method and technology of metal workpieces, applied in the production field of bimetal seamless embedded casting workpieces, can solve the problems of waste of human and material resources, high cost, low production capacity, etc., and achieve saving of human and material resources, low cost and high production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

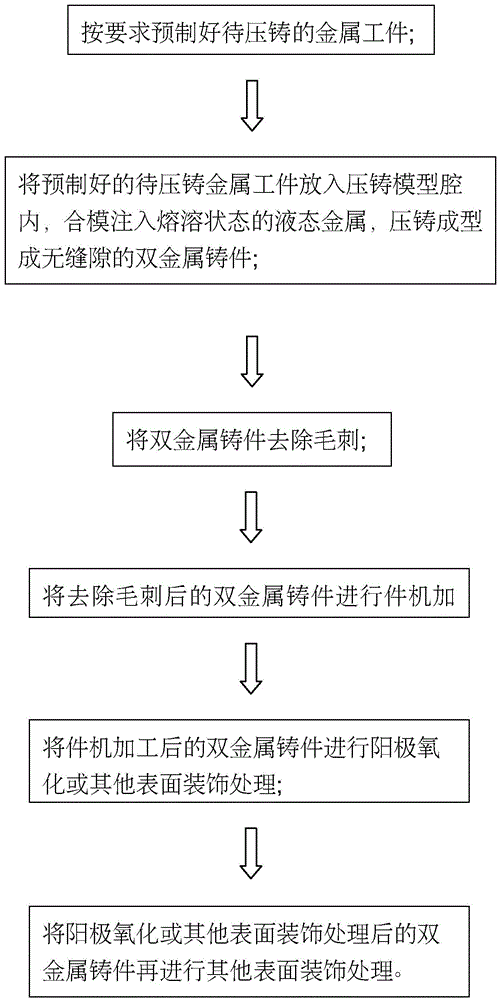

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below, but not as a limitation of the present invention.

[0021] At present, the existing production method of metal casings for high-end mobile phones, tablet computers, notebook computers, and cameras is as follows: the metal (aluminum alloy, stainless steel, titanium alloy) blank is formed into a preliminary shape by multiple times of forging and then mechanically processed into a finished product. Or use sheet metal to directly machine into finished products. The machining process requires a lot of cumbersome processing by CNC. The processing process wastes a lot of human and material resources, low efficiency, low production capacity and high cost, which cannot meet the huge market demand. In order to solve the above-mentioned deficiencies in the prior art, after continuous research and exploration of the die-casting technology, a production method of the bimetal seamless embedded casting workpiece of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com