Circle finishing chamfering device used for tube stock

A technology for chamfering and pipe material, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems affecting the welding quality of pipe fittings and pipes, the socket and socket of pipes and pipe fittings are not in place, and increase the difficulty of construction. Burr-free, clogging-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

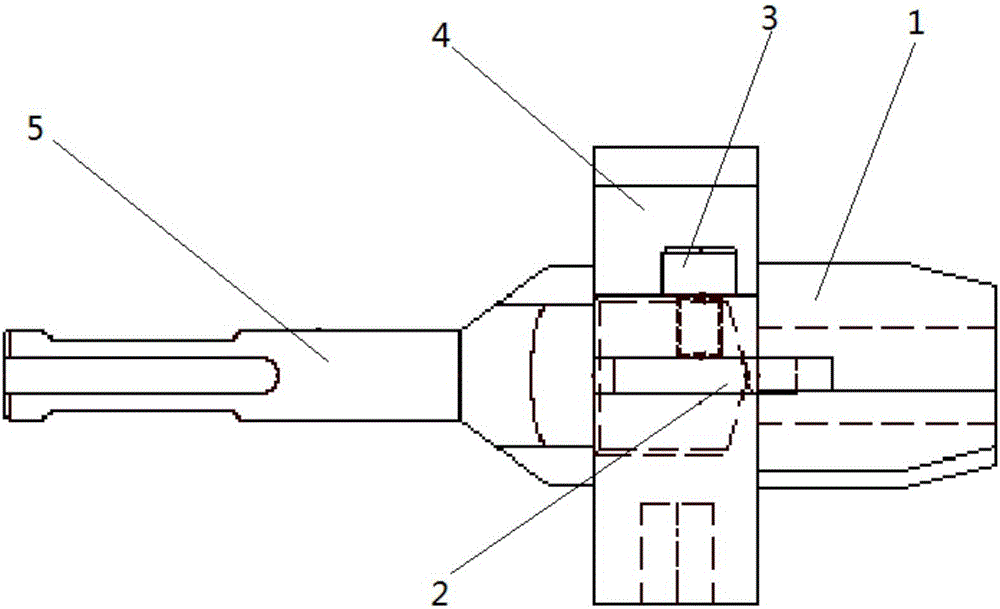

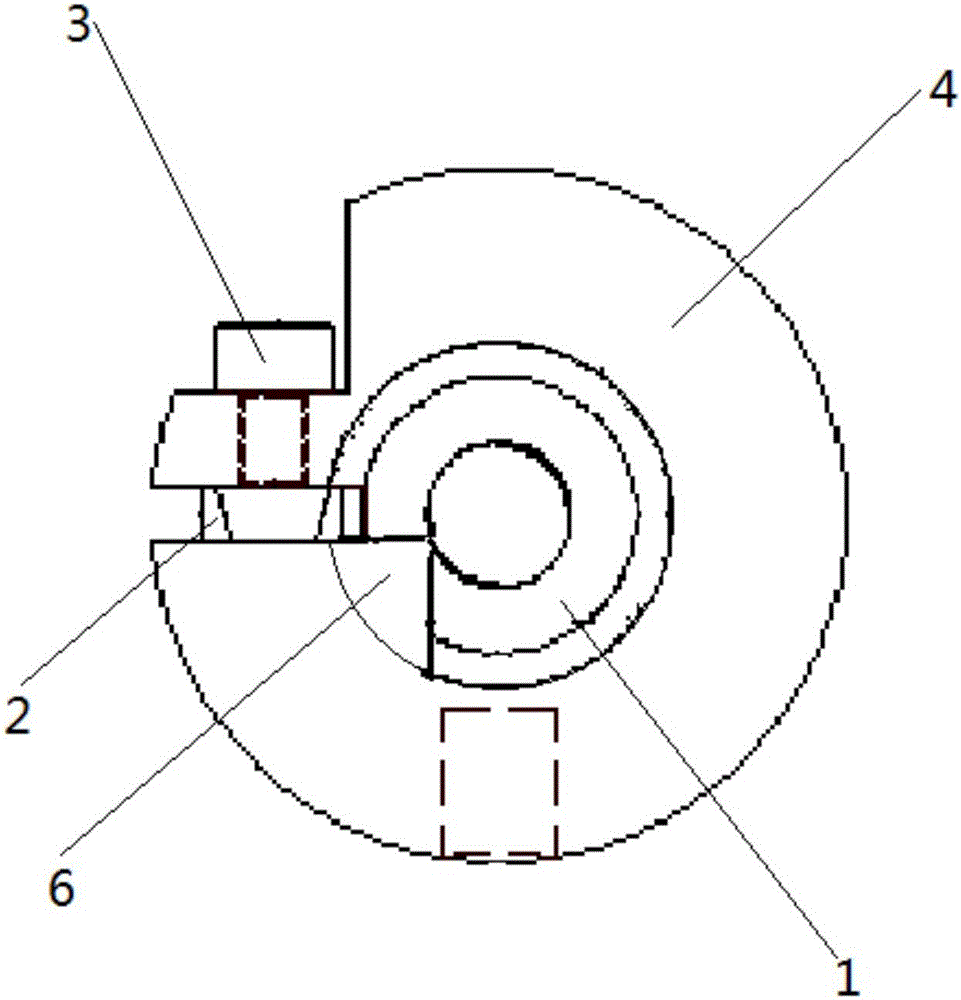

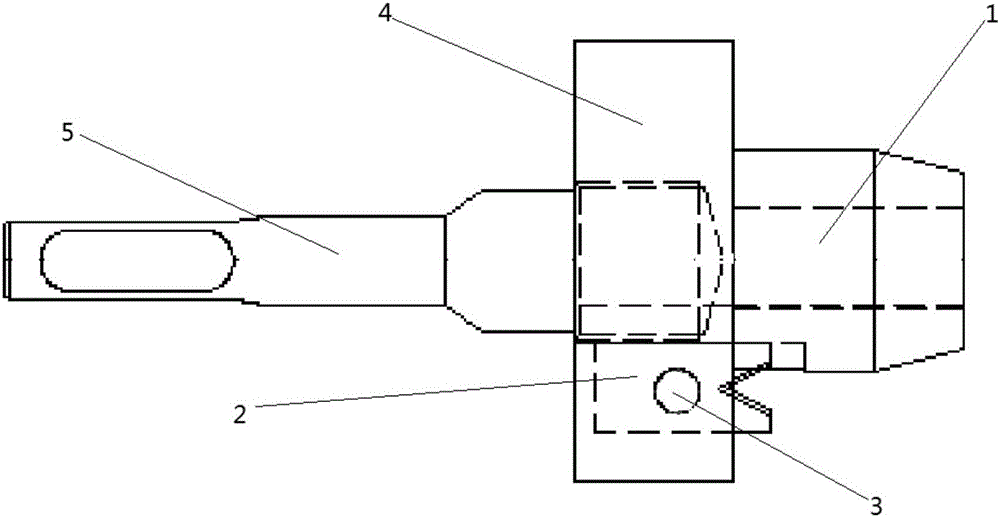

[0015] The full-circle chamfering device for pipes includes the main body of the full-circle chamfering device. The main body of the full-circle chamfering device includes the full-circle mechanism 1, the chamfering mechanism and the fixing piece 4. The top of the full-circle mechanism 1 can be inserted into the inner diameter of the pipe, and the bottom The end is connected with the fixing part 4 , the rounding mechanism 1 includes a cylindrical structure, one end of the cylindrical structure is connected with the bottom surface of a truncated cone structure, and the other end of the cylindrical structure is connected with the fixing part 4 .

[0016] The chamfering mechanism is a cutting blade 2 with a "V"-shaped structure at the top, the bottom of the cutting blade 2 is embedded in the fixing part 4, and the "V"-shaped structure at the top protrudes and is located on one side of the bottom of the full circle mechanism 1. One side of the cutting blade 2 is embedded in the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com