Automatic punching device provided with multiple drill bits

A punching device and multi-drill technology, which is applied in metal processing and other directions, can solve the problems of poor stability and low yield of punching devices, and achieve the effects of ensuring cleanliness, saving manpower workload, and simple division of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0018] The invention will be described in detail below with reference to the accompanying drawings and examples.

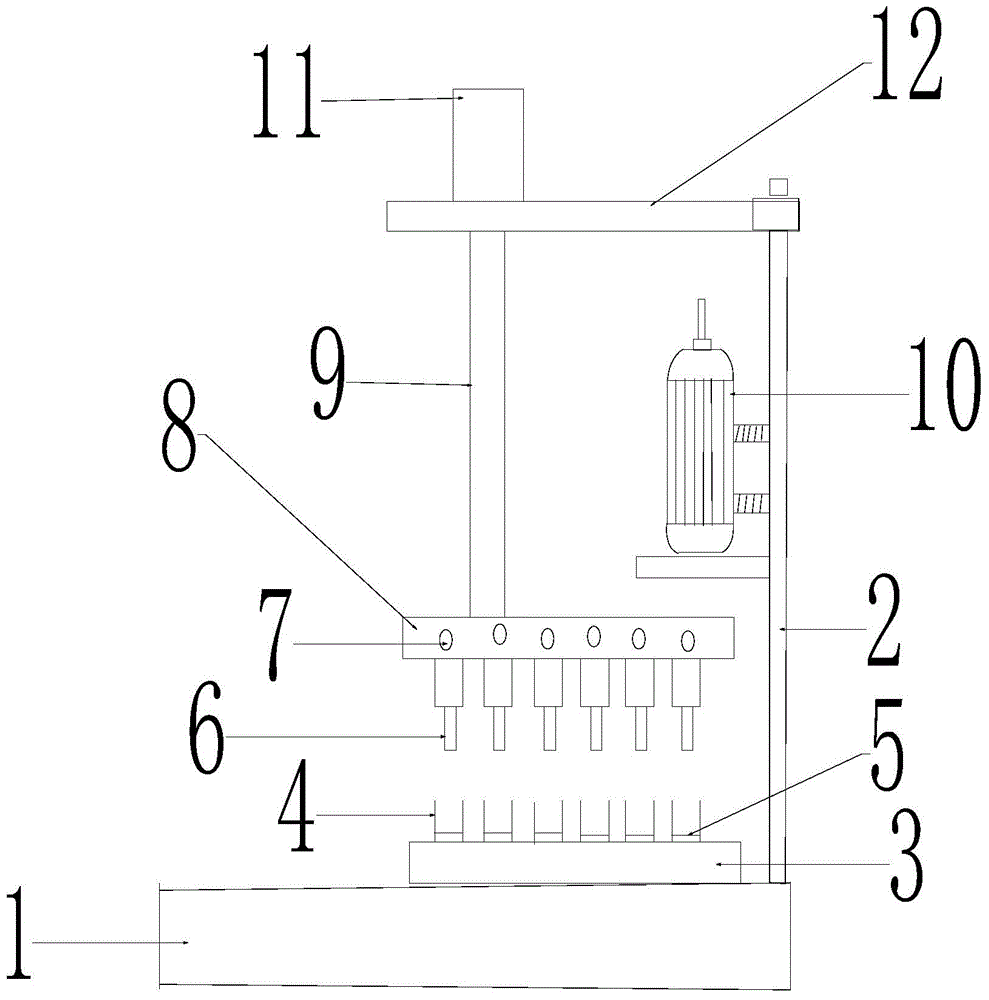

[0019] The multi-bit automatic drilling device includes a base 1, a bracket 2, a support plate 3, a baffle plate 4, a vertical slide seat 5, a drilling bit 6, a waste outlet 7, a pressure plate 8, a connecting rod 9, an engine 10, a driving mechanism 11, Cross bar 12, support plate 3 is fixed on the base 1, six pairs of baffles 4 are arranged on the support plate 3, a vertical sliding seat 5 is installed in the middle of each pair of baffles 4, bracket 2 is fixed on the edge of base 1, and bracket 2 An engine 10 is provided, a cross bar 12 perpendicular to the support 2 is provided on the top of the support 2, and a driving mechanism 11 is arranged above the cross bar 12. The driving mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com