An oven cigarette clip loading and unloading device

A technology for loading and unloading equipment and cigarette clips, which is applied in the fields of tobacco, tobacco preparation, transportation and packaging, etc., can solve the problems of reducing the quality of tobacco leaves, the cigarette clip cannot be placed in a designated position, and the efficiency is reduced, so as to improve space utilization and ensure Quality and integrity, reducing the effect of not being placed in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

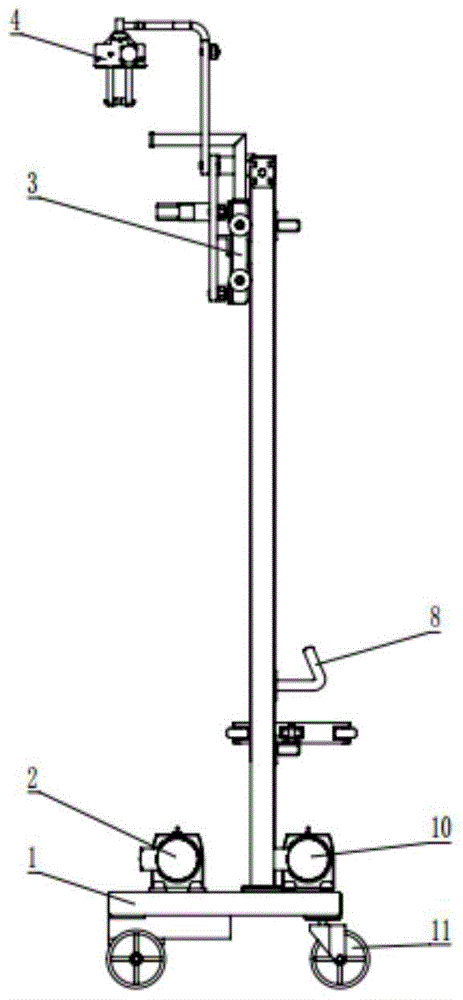

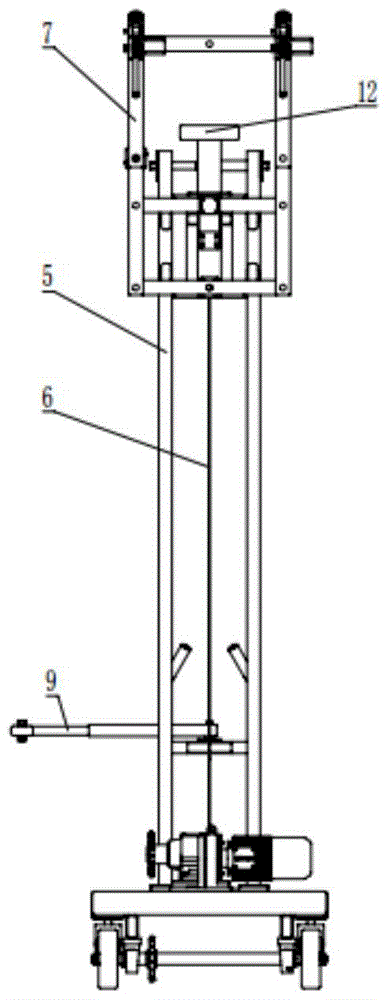

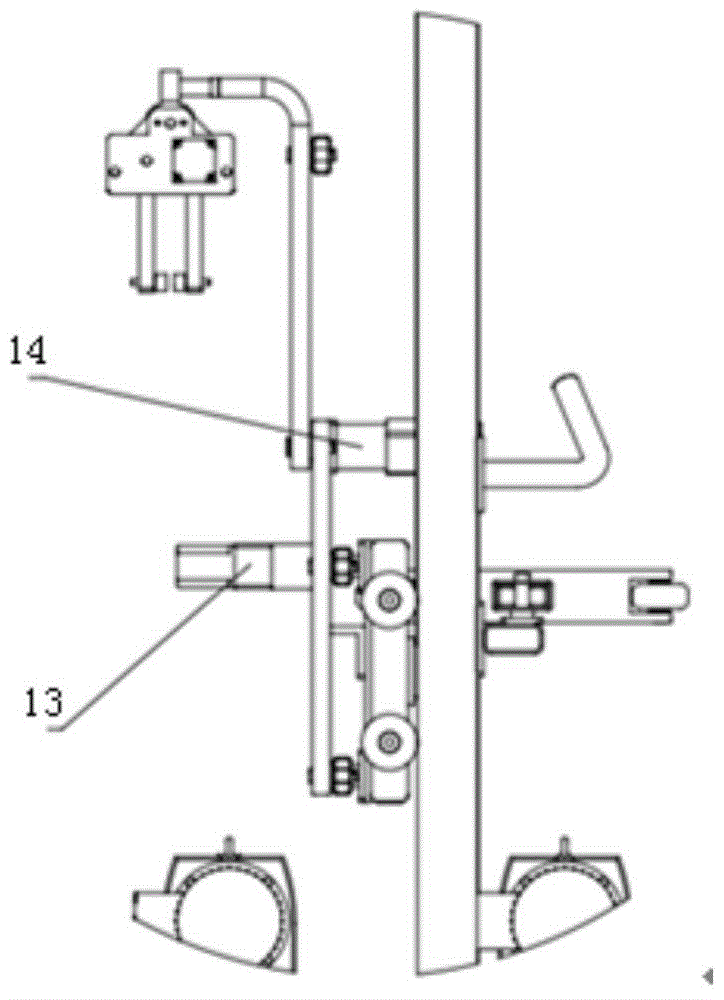

[0031] Depend on figure 1 and figure 2 It can be seen that an oven cigarette clip loading and unloading device includes a device body, a rotary lifting device 7 for lifting the cigarette clip, and a clamping device for grasping the cigarette clip, wherein the device body includes a support base 1 and is fixed on the support The vertical bracket at the upper end of the seat 1, the rotating lifting device 7 is installed on the vertical bracket, the clamping device is installed on the rotating lifting device 7, and the rotating lifting device 7 can keep the clamped cigarette clip horizontal Lifting and rotating movements on the ground, or lifting and rotating movements inclined relative to the ground.

[0032] Described rotary elevating device 7 comprises bearing, a parallelogram frame and first vertical rod 18 and the second vertical rod 19 that are connected with the first vertical lifting rod 16 of parallelogram frame and the second vertical lifting rod 20 respectively, para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com