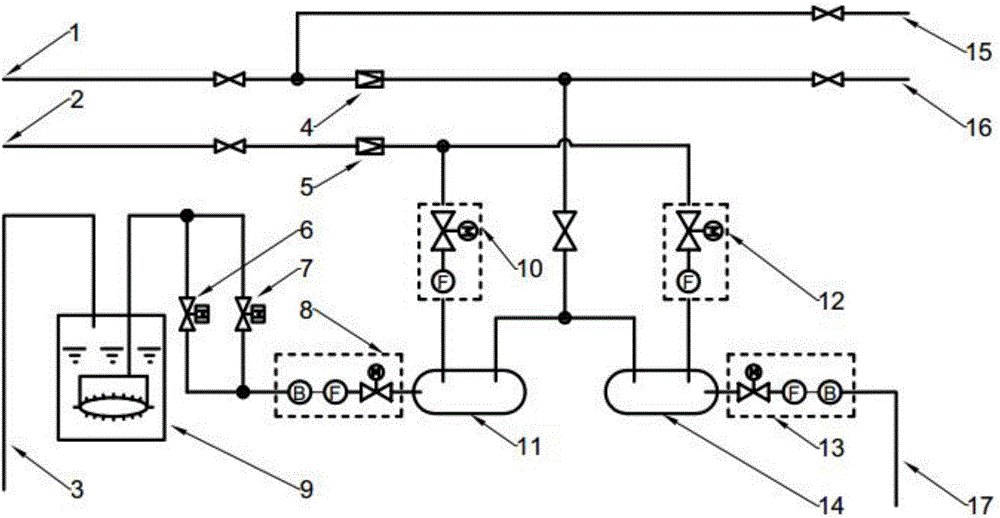

Novel silicon steel continuous annealing furnace nitrogen-hydrogen ratio humidification device and continuous annealing decarburization method

A technology of continuous annealing furnace and humidification device, applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problems of insufficient blowing and carbon increase, achieve high uniformity, avoid large fluctuation of furnace pressure, and avoid the proportion of hydrogen excessive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A typical silicon steel strip decarburization process using a new silicon steel continuous annealing furnace nitrogen-hydrogen ratio humidifier is shown in Table 1:

[0026] Table 1 Typical silicon steel strip decarburization process

[0027] serial number

[0028] According to the above embodiments, when the carbon content of the silicon steel raw material is 30-50ppm, the carbon content of the finished silicon steel product can be reduced to 27ppm through the continuous annealing and decarburization process, thereby reducing the loss of silicon steel and increasing the magnetic polarization to meet customer needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com