Automatic cutting technology for cloth

A cloth and automatic technology, which is applied in the cutting of textile materials, marking of textile materials, textiles and papermaking, etc., can solve the problems of no coding of cloth, confusion in use, waste, etc., and achieve good results, improve quality, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

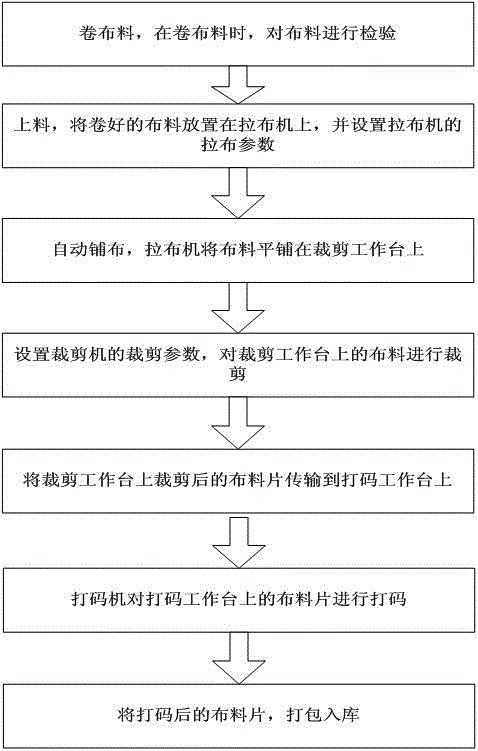

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] The automatic cloth cutting process of the present invention inspects the cloth when rolling the cloth, removes the defective cloth section, improves the quality of the cut cloth piece, and codes the cut cloth piece to facilitate subsequent use, management, and stacking , easy to use, good effect, such as figure 1 As shown, it specifically includes the following steps,

[0022] Step (1), roll the fabric. When rolling the fabric, inspect the fabric. If the fabric is flawed, stop rolling the fabric, cut off the fabric at the flaw, and roll the fabric. If the fabric is flawed, stop rolling the fabric. The fabric at the defect is cut off, and the fabric is being rolled to remove the defective fabric section to improve the quality of the cut fabric piece;

[0023] Step (2), loading, place the rolled fabric on the stretching machine, and set the stretching parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com