Multiple steel wire induction heating and water-cooling production line

An induction heater and water heating technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of high energy consumption per unit output, low production efficiency, and environmental pollution, and achieve high production efficiency, low cost, and induction fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

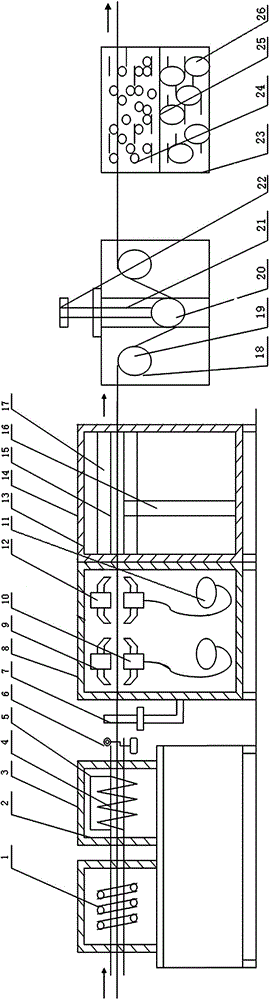

[0027] Such as figure 1 As shown, the multi-wire induction heating water cooling production line of the present invention includes an induction heater 1, a constant temperature device 2, a steel wire carding mechanism 7, a water mist cooler 9, an isothermal treatment device 13, and an oxide skin peeling mechanism arranged in sequence. 18 and the cleaning mechanism 23, a plurality of steel wires are subjected to induction heating, temperature maintenance, carding, and then enter the water medium to cool and keep warm through various devices arranged in sequence, and then peel off and remove the surface oxide skin.

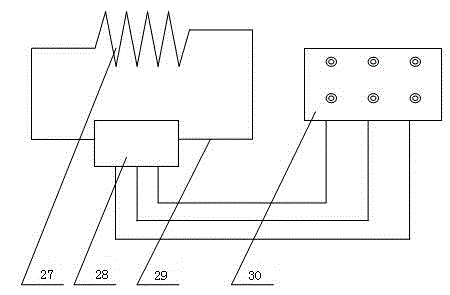

[0028] refer to figure 2 , In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com