Method for dry-etching silicon groove

A dry etching, silicon groove technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as increased scrap rate, processing cost impact of processing cycle, device failure, etc., to reduce processing costs and reduce processing costs. The steps are clear and orderly, and the product quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

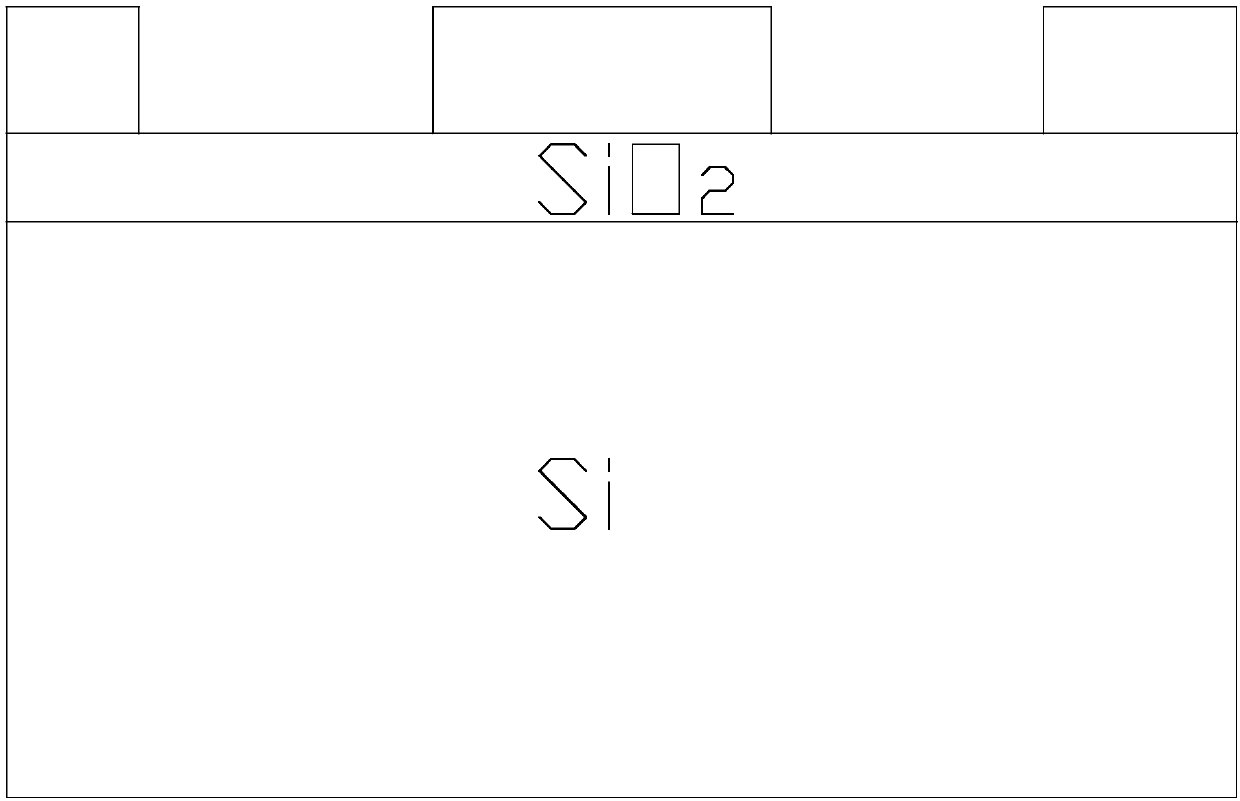

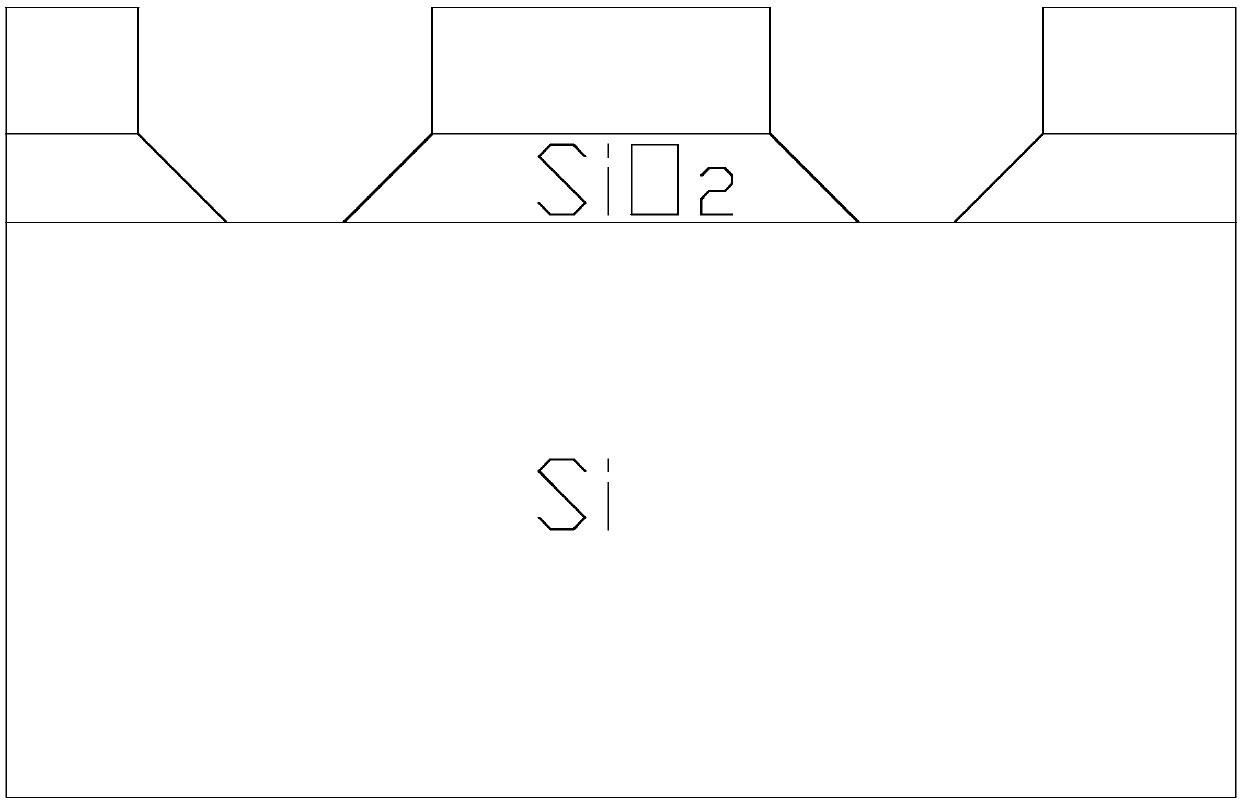

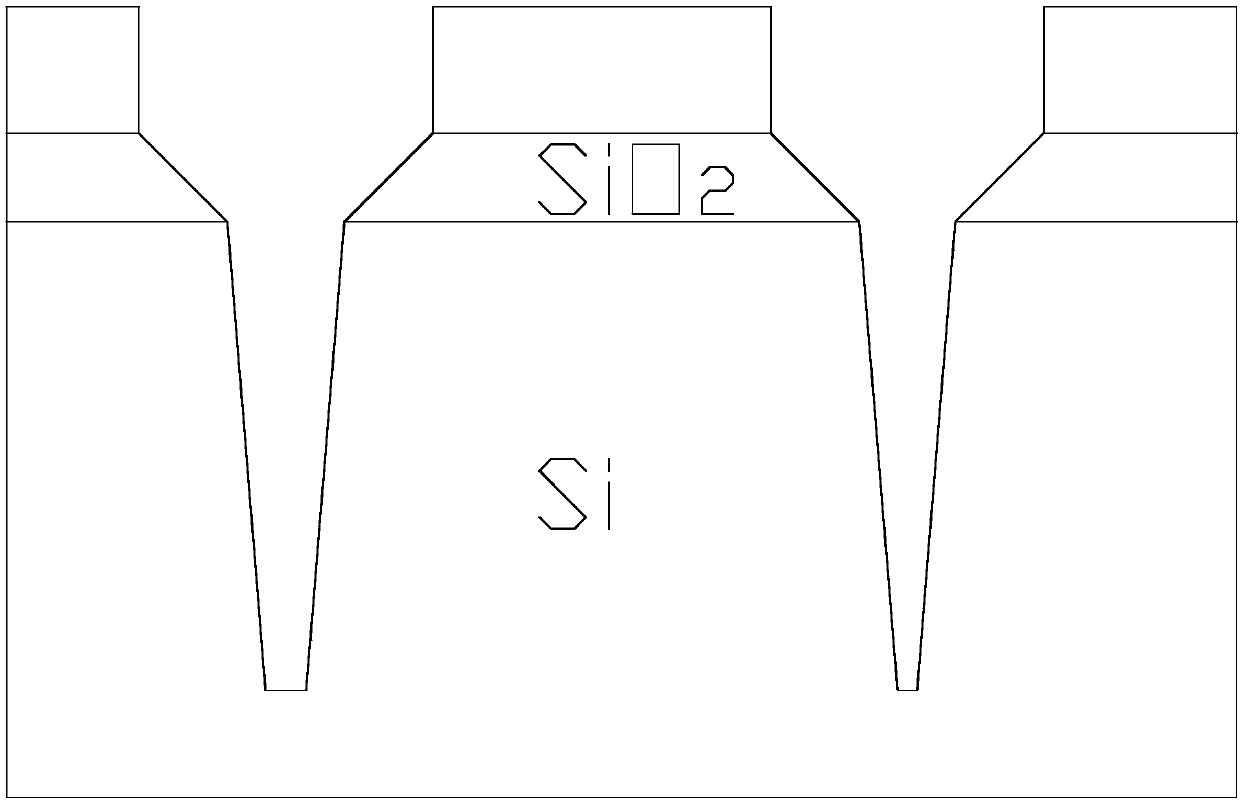

[0016] The invention as Figure 1-3 shown, follow the steps below:

[0017] 1) Place photoresist: place photoresist according to the position of the preset pattern;

[0018] 2) Preparation of mask layer: through Ar, CHF 3 、CF 4 Etching several trenches on the silicon oxide to form a mask layer;

[0019] 3), etching silicon groove: through Cl 2 , SF 6 , Ar physically etch silicon under the action of a high-frequency electric field; complete. Even with Cl 2 Add to SF 6 With the formulation of Ar, adjust the bombardment voltage (bias electric field) of the chassis to physically etch silicon. The formulation starts with Cl 2 , AR as the main body, SF 6 is fine-tuning, where SF 6 It is isotropic etching, but it can be used to fine-tune the rate of etching Si to meet the requirements of production efficiency, and at the same time, it can avoid the "pit" at the bottom of the silicon groove caused by the rebound of the Cl-based process on the side wall of the silicon groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com