Solid-liquid two-phase energy dissipating fender and manufacturing method thereof

A cancellation and fender technology, applied in shipping equipment, climate change adaptation and other directions, can solve the problems of secondary injury to ships or personnel, and can not be reused, and achieve the effect of good buffering energy absorption and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

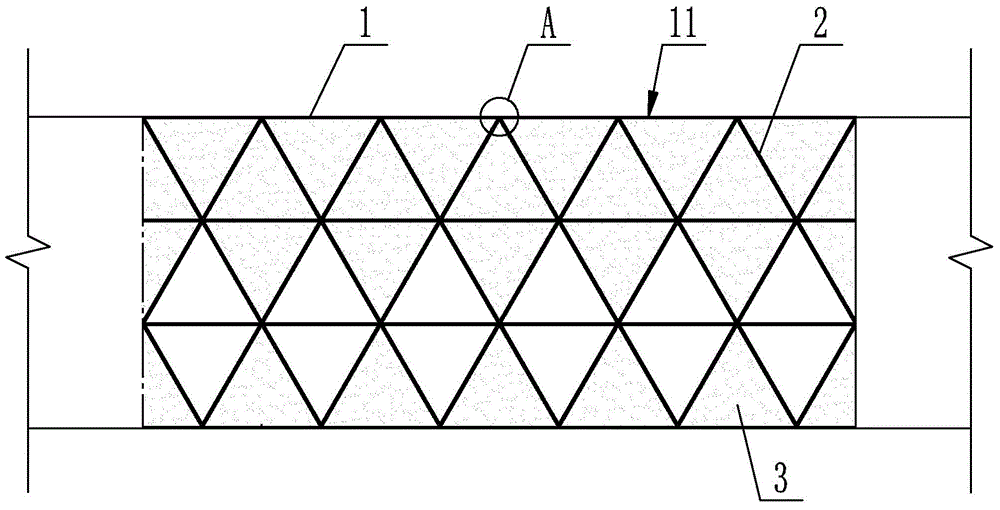

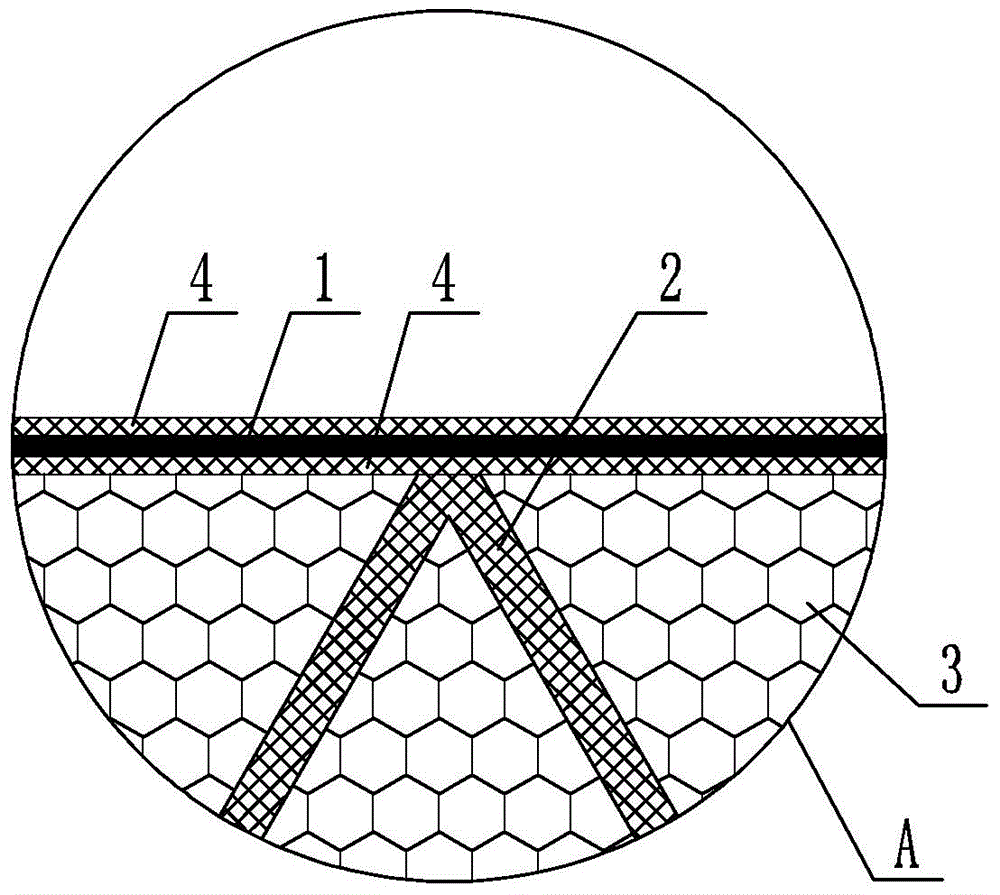

[0032] A solid-liquid two-phase energy-dissipating fender includes an outer shell 1 and a hollow tube 2 arranged inside the outer shell 1. The material of the outer shell 1 can be steel, composite material, or steel-clad composite material or composite material-clad steel. In this example, if figure 2 As shown, the shell 1 is a steel plate, and the inner and outer surfaces of the steel plate are provided with an anti-corrosion layer 4 .

[0033] The shell 1 has a collision surface 11, and the hollow tubes 2 are integrally formed with the shell 1, and two adjacent hollow tubes 2 are in surface contact and tightly fitted, and the hollow tubes 2 are arranged and combined to fill the entire inner space of the shell 1. The shape of the hollow tube 2 is a prism, such as a triangular prism or a quadrangular prism. The cross-sections of the prisms are respectively triangular or square. Two adjacent hollow tubes 2 are in surface contact with each other on the sides of the prism. The ...

Embodiment 2

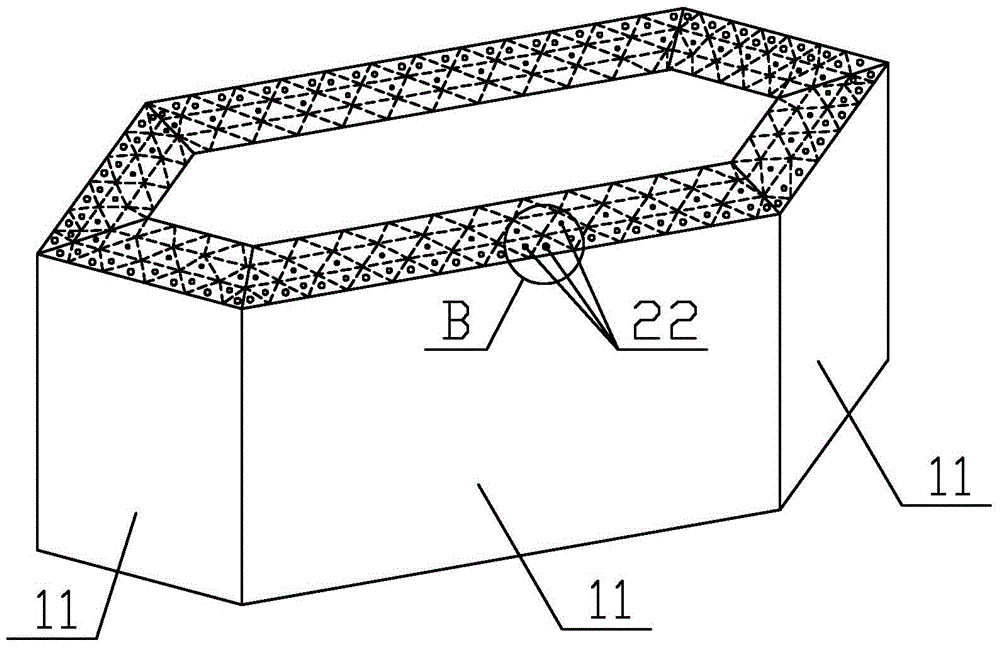

[0040] This embodiment is roughly the same as Embodiment 1, the difference is that, as Figure 5 As shown, the injection of the hollow tube 2 filled with the liquid 3 is realized in that the hollow tube 2 is a closed structure, and the hollow tube 2 filled with the liquid 3 has a prestressed hole 22 that can be broken after being hit, and the prestressed hole 22 and The remaining parts of the hollow tube 2 jointly form a hollow structure for filling the liquid 3 . The prestressed hole 22 is a closed structure before being hit by an external force, and the hole will be broken after being hit. In this embodiment, the thickness of the prestressed hole 22 is smaller than that of its surroundings. The thickness of the prestressed hole 22 is related to the impact force, and it can be designed that when a certain impact force is reached, the prestressed hole 22 will be broken. After the prestressing hole 22 is broken, the liquid 3 in the hollow tube 2 will be sprayed out to achieve...

Embodiment 3

[0043] This embodiment is roughly the same as Embodiment 1, the difference is that, as Figure 7 As shown, the diameter of the hollow tube 2 filled with the liquid 3 gradually decreases from the collision surface 11 inward as the collision depth increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com