Device for transferring heat in solid energy storage body by means of high-temperature steam

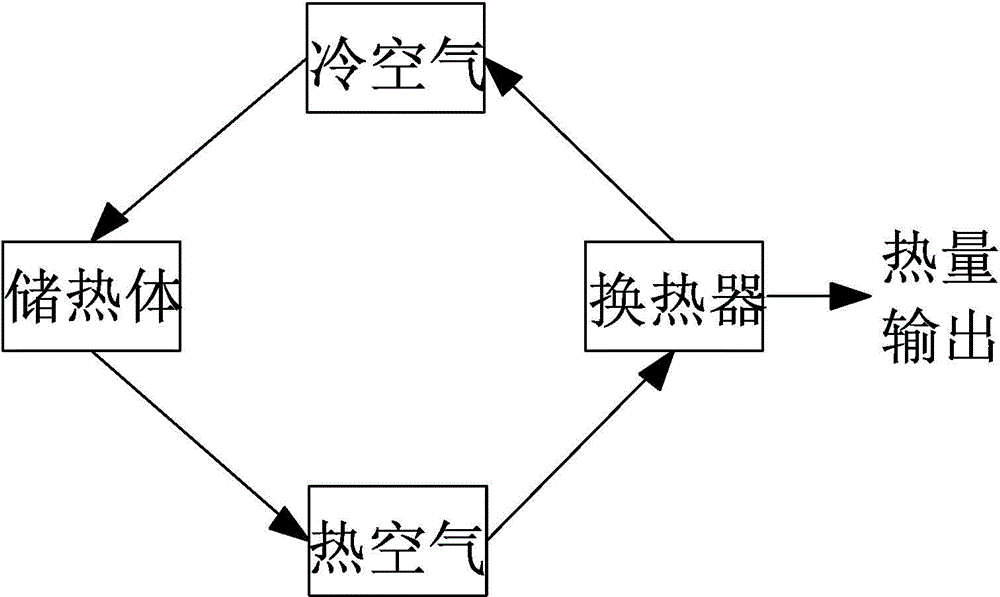

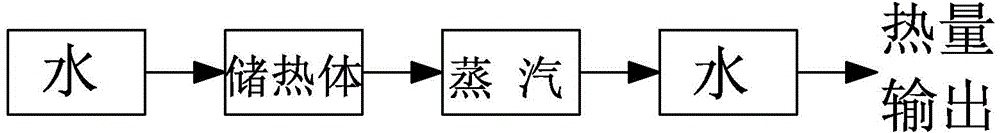

A high-temperature steam and heat storage device technology, applied in the field of electric energy control, can solve the problems of low heat storage and slow heat transfer speed, and achieve the effects of increasing heat storage, solving slow heat transfer speed, and increasing heat storage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

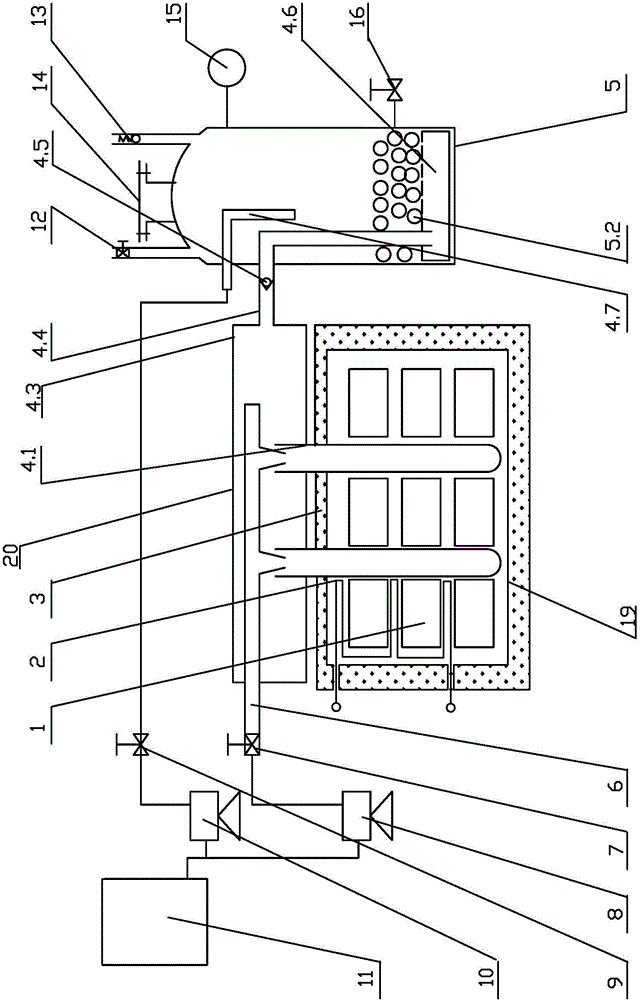

[0031] Embodiment: Turn on the power during the off-peak time, the current flows through the heating wire 2, and the heating wire 2 releases heat to heat the solid heat storage material 1 to 100----1000°C to complete the heat storage process. When the pure water tank 11 is full of pure water, turn on the supplementary water pump 10 and the controller 9, inject pure water into the saturated steam generator 5, control the liquid level to be higher than the filler 5.2, and lower than the height of the saturated steam generator 5. one-third. Then the high-temperature steam water feed pump 8 is turned on, and the water flow is regulated by the flow regulating valve 7. The water flows through the high-temperature steam water pipe 6 and enters the heating pipe 4.1 inside the high-temperature steam generator 20 . Since the high-temperature solid heat storage material 1 conducts heat to the heating tube 4.1 by means of heat radiation and heat conduction, and the temperature of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com