Mulch recycling machine

A technology of removing machine and plastic film, applied in the field of agricultural machinery, can solve the problems of damage to the picking mechanism, increase the difficulty of residual film, hinder the picking up of residual film, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

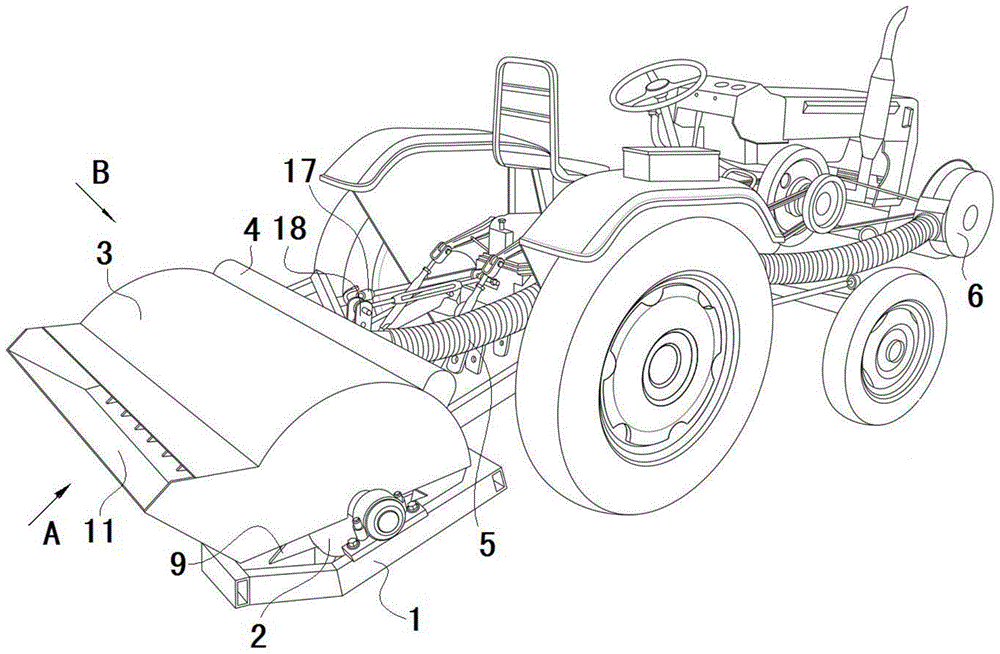

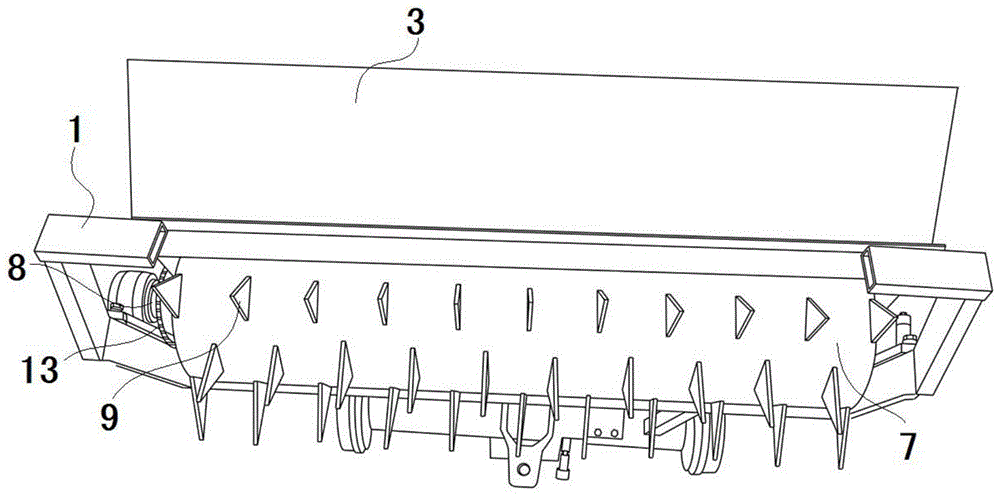

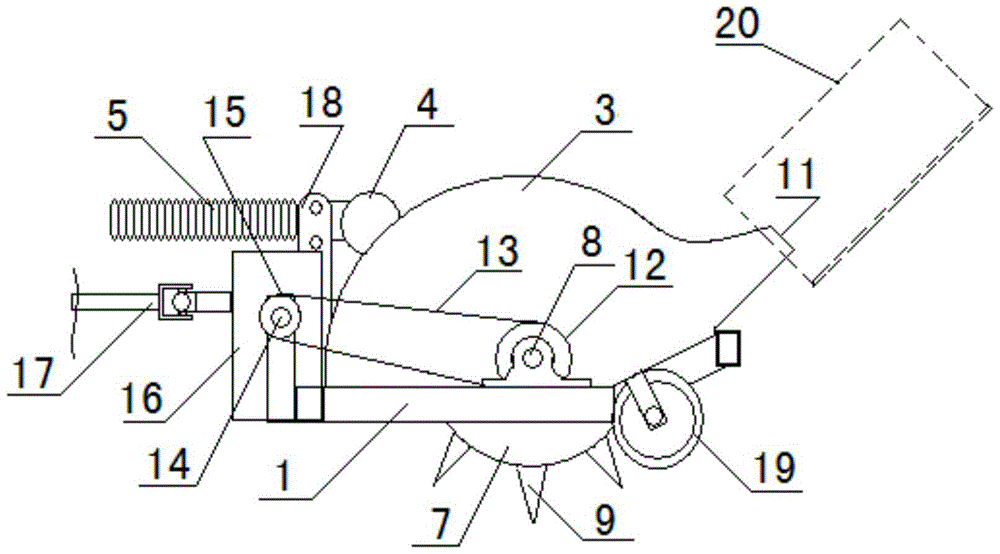

[0022] attached by figure 1 , 2 , shown in 3 and 5: the mulch recovery clearing machine comprises frame 1, the mulch picker 2 that is arranged on the frame 1, the exhaust hood 3 that is arranged on the mulch picker 2 on the frame 1, is arranged on the exhaust The airflow distributor 4 on the cover 3 is connected to the air supply pipe 5 of the airflow distributor 4, and the blower fan 6 connected to the end of the air supply pipe 5. The mulch pick-up device 2 is arranged at the center of the pick-up roller 7 by the pick-up roller 7 The transmission shaft 8 and the multiple rows of pick-up claws 9 uniformly arranged on the circumference of the pick-up roller 7 are composed of the exhaust hood 3, which is a semi-cylindrical structure, with a row of air intake holes 10 on the inner side along the axial direction, and the outer side is inclined upward. There is a rectangular waste film discharge port 11 along the axial direction.

[0023] attached by figure 1 and 4 As shown: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com