A strip tail positioning control method for cold tandem coiler

A positioning control and coiling machine technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as inaccurate positioning, achieve easy maintenance, increase yield, and save capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

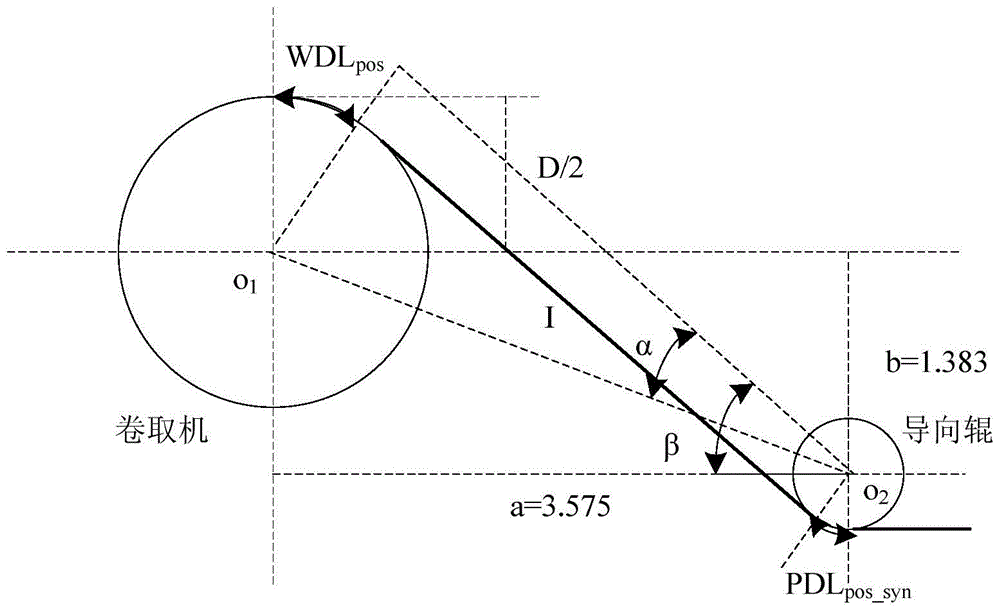

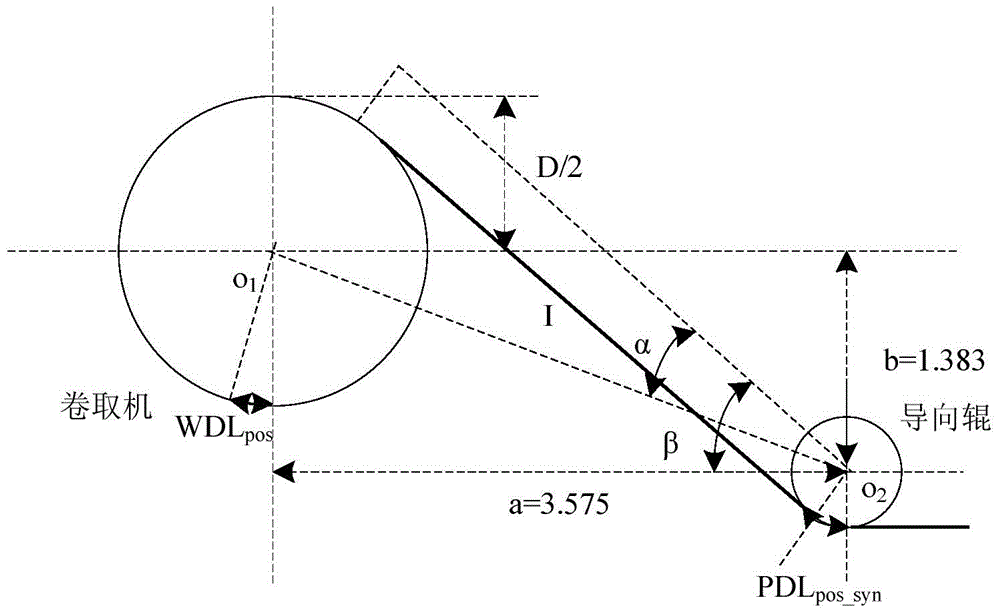

[0049] The strip tail positioning control method of the cold rolling coiler of the present invention takes the minimum strip tail positioning deviation as the objective function, and establishes a whole set of speed, primary length positioning and secondary length positioning control methods for the strip tail positioning control of cold-rolled strip steel products , to obtain the best tail positioning effect.

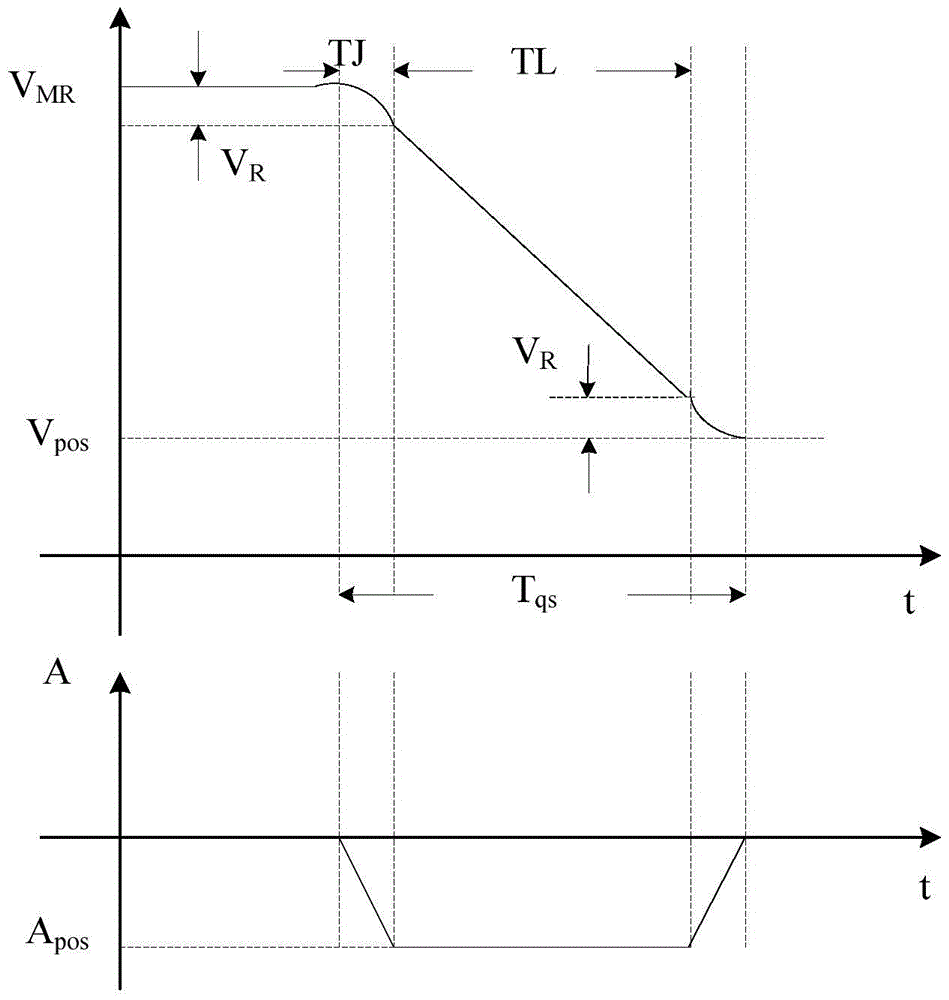

[0050] 1. Tail positioning speed calculation model

[0051] The process of strip positioning is to determine the length of the tail of the strip to be positioned, and to control the speed ramp positioning according to the actual length feedback from the tension roller in real time. When shearing occurs, the flying shears cut the strip into two parts, the first part continues to be coiled on the coiler, and the latter part continues to run forward, ready to be threaded on the other coiler. When the "cutting finished" signal is sent out, the strip tail on the coiler mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com