Aircraft using distributed electric ducted fan flap lift-rising system

A ducted fan, distributed technology, applied in the field of aircraft using distributed electric ducted fan flap lift system, can solve the problems of unsuitable use of electric mode, large lift coefficient, large frictional resistance, etc., to achieve improved Economy and load capacity, the effect of improving economy and load capacity, increasing the lift-to-drag ratio and lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019]The aircraft that can be formed by the combination of the fuselage and the fuselage and the distributed electric ducted fan flap lift system described in the first embodiment is different from the fuselage described in the second embodiment, the fuselage and the distributed electric duct The other parts of the aircraft that can be constituted by the combination of the fan flap increased lift system have the same structure, and the combination of the fuselage described in Embodiment 1 and the fuselage and the distributed electric ducted fan flap increase system can be achieved below. Taking the constituted aircraft as an example, continue to describe the structure of other parts of the aircraft.

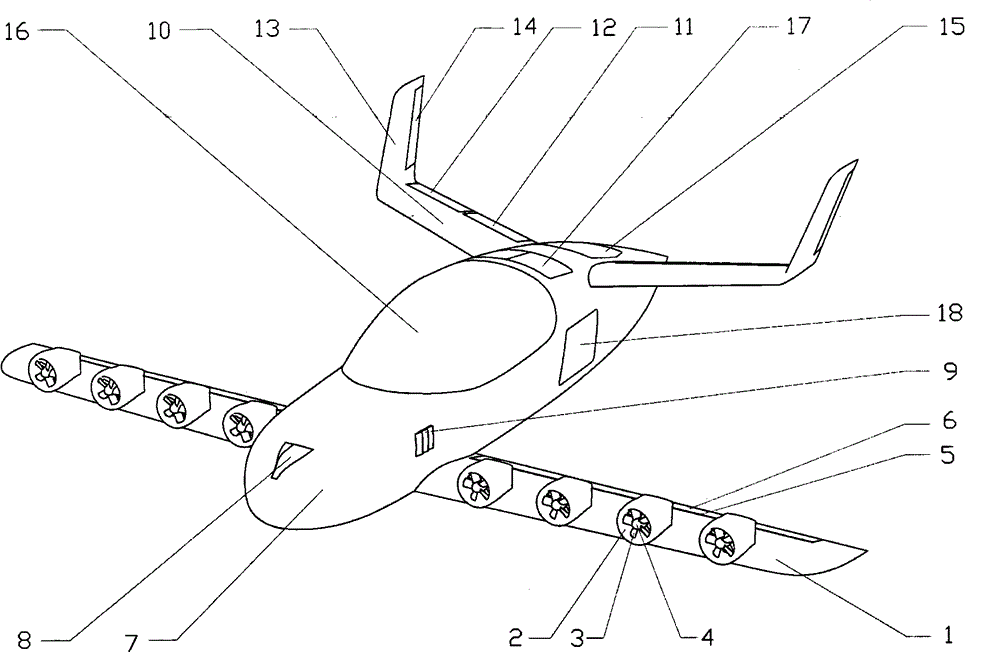

[0020] Such as figure 1 , shown in 2, the lift fan 20 is one, the air inlet of the lift fan 20 is provided with a cover plate 15 that can be opened and closed toward the head of the fuselage as required, and the exhaust port is provided with a longitudinal deflection panel that ...

Embodiment 2

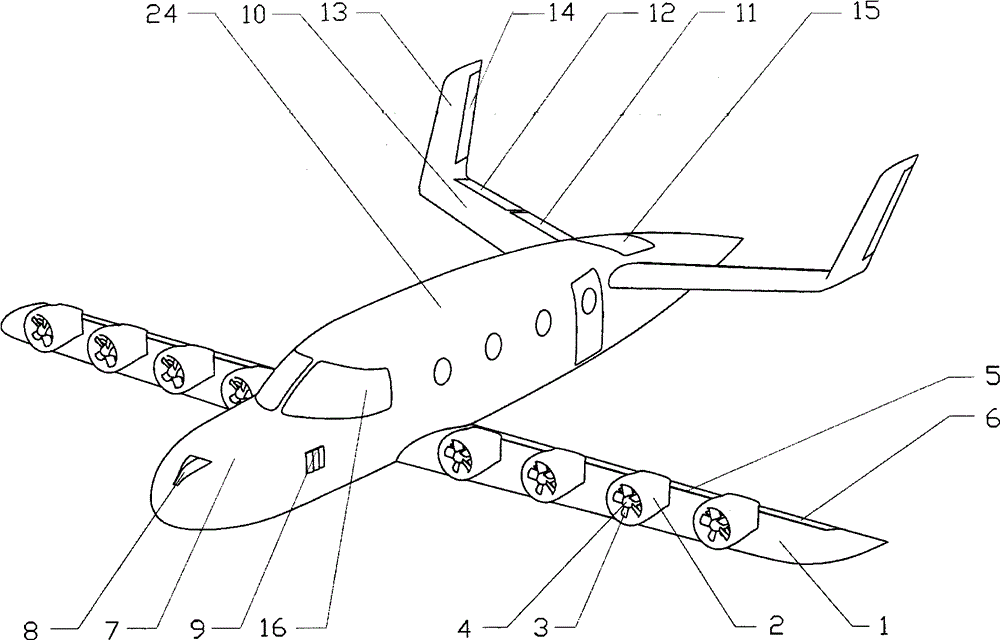

[0036] The aircraft in the form of a business jet that can be formed by the combination of the fuselage and the fuselage and the distributed electric ducted fan flap increase system described in the second embodiment is the same as the fuselage and the distribution of the fuselage described in the first embodiment. The working process of the household form aircraft that can be formed by the combined mode of the electric ducted fan flap increasing the lift system is the same, so it is no longer repeated.

[0037] In this embodiment, when the aircraft is flying in the vertical take-off and landing state and the horizontal flight state, it is necessary to use the control stabilization system for manual stabilization.

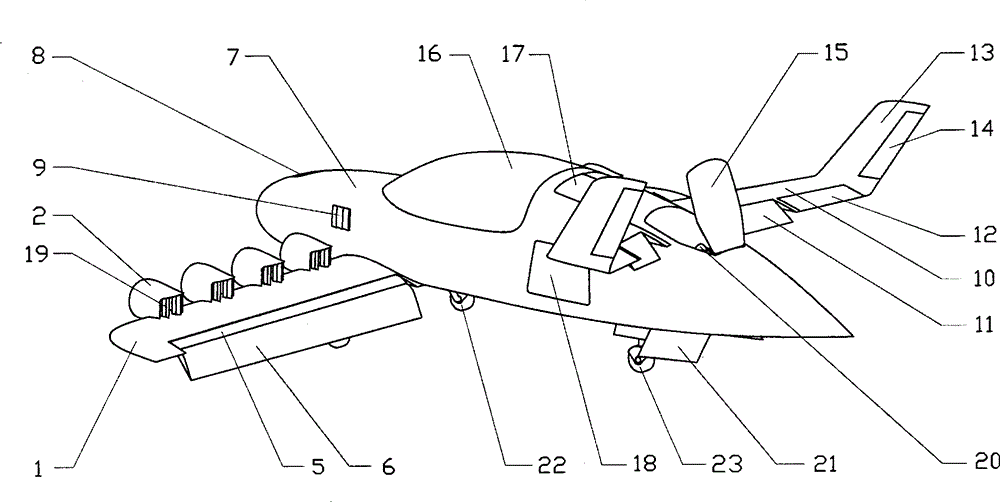

[0038] Present embodiment aircraft is arranged on the front part of fuselage because two distributed electric ducted fan flaps increase lift system, and the duct 2 of each electric ducted fan has left and right two facades, and these facades are as The vertical tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com