Stepping type trash can

A trash can and stepping technology, applied in the field of garbage storage equipment, can solve the problems of complex structure, environmental pollution and easy overturning of stepping trash cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

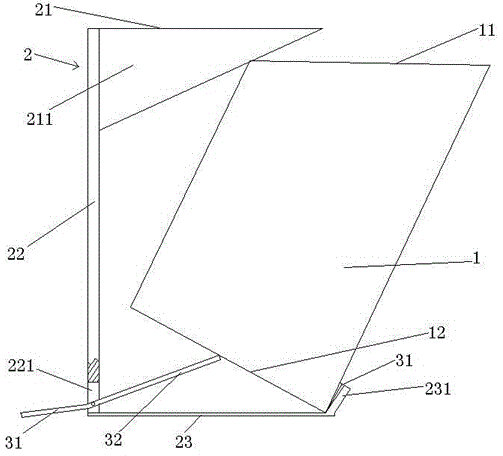

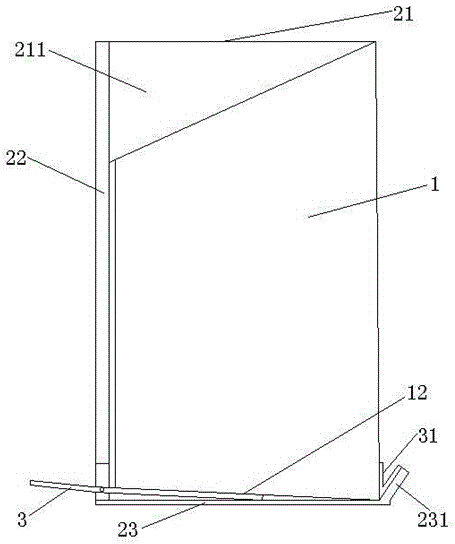

[0017] Such as figure 1 with figure 2 The stepping trash can shown includes a bucket body 1 and a frame body 2, and the frame body 2 includes a horizontally placed top plate 21 and a bottom plate 23 and a vertical plate 22 connecting the ends of the top plate 21 and the ends of the bottom plate 23,

[0018] The bucket body 1 is placed in the frame body 2,

[0019] At the opening 221 at the bottom of the vertical plate 22, a seesaw 3 is installed. The seesaw 3 includes a pedal 31 and a lifting plate 32. The joint between the lifting plate 32 and the pedal 31 is hinged with the vertical plate 22. The pedal 31 stretches out vertical plate 22, lifting plate 32 is on the base plate 23, barrel body 1 is placed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com