Multipurpose belt deviation correcting device

A correction device and multi-purpose technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of inability to realize real-time control of the positive belt, loose structure of the deviation correction device, and poor working environment of the conveyor belt, etc., to achieve Compact structure, improved service life and high adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

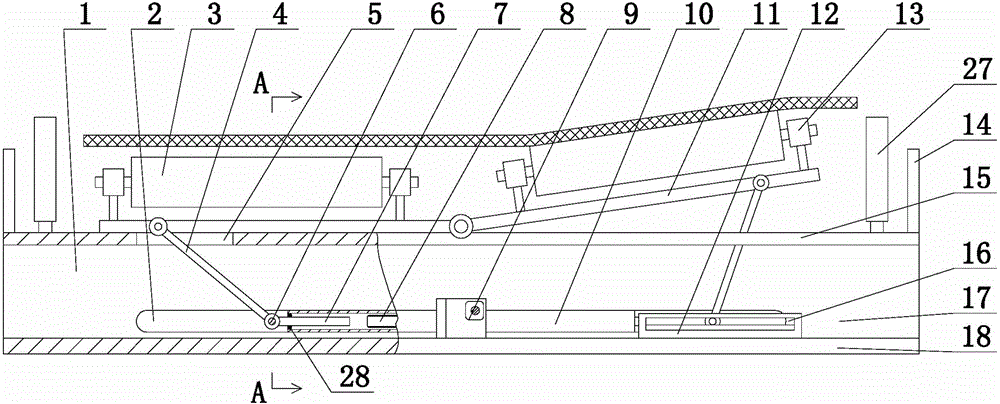

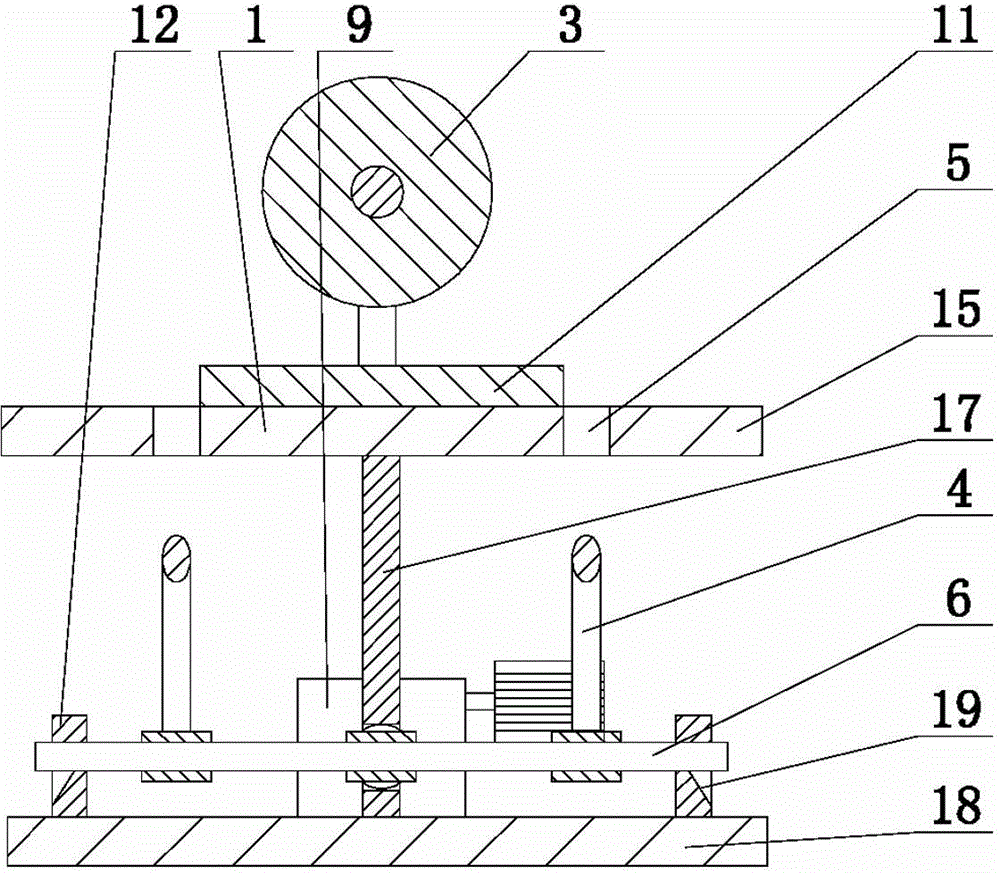

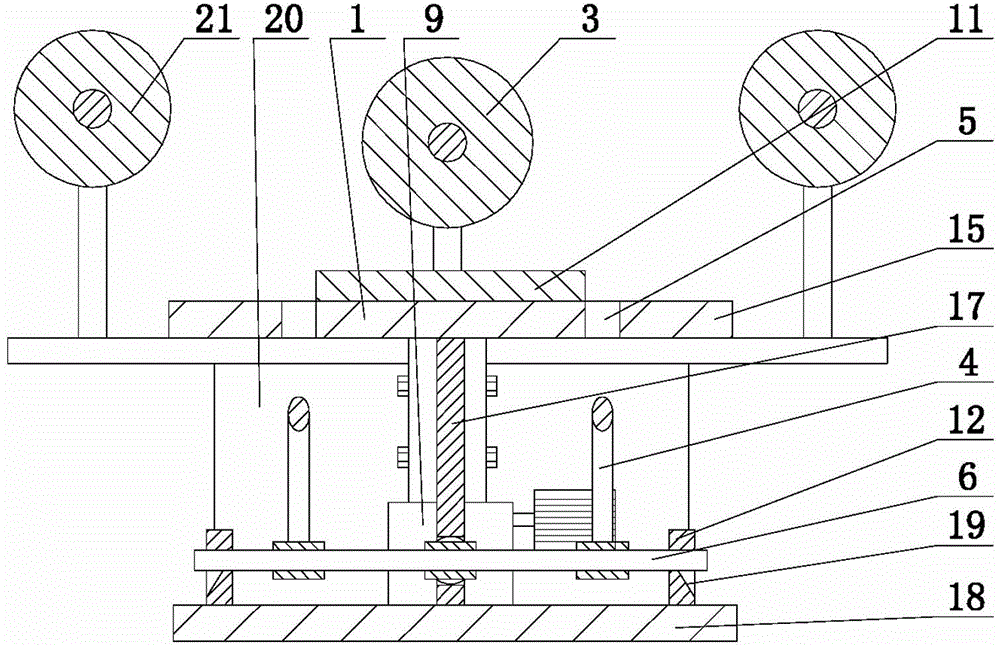

[0029] The present invention includes a frame 1, which is characterized in that: both sides of the upper surface of the frame 1 are provided with overturning frames 11, and both overturning frames 11 are provided with deflection adjustment rollers 3 through bearings 13, and the opposite ends of the two overturning frames 11 are on the same machine The frame 1 is hinged; the bottom of the flip frame 11 is hingedly provided with a pole 4; the frame 1 is provided with a lead screw reducer 9, and the two sides of the lead screw reducer 9 are screw rods 8, and the two parts in the frame 1 Both ends are provided with slideway groups 12, and both slideway groups 12 are provided with slide rods 6, and the two slide rods 6 are respectively provided with ejector rods 7 corresponding to the screw rods 8 on both sides of the screw reducer 9; The poles 4 at the bottom of the two overturning frames 11 are hinged with the two slide bars 6 respectively.

[0030] As a preferred solution of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com