Piston cylinder rotation type air pressure multi-disc friction clutch

A technology of friction clutches and piston cylinders, which is applied in the direction of friction clutches, clutches, fluid-driven clutches, etc., can solve problems such as abnormal operation of friction clutches, increased leakage, high purchase, maintenance and repair costs, and expand the application field and application range, reduce manufacturing and use costs, and improve the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

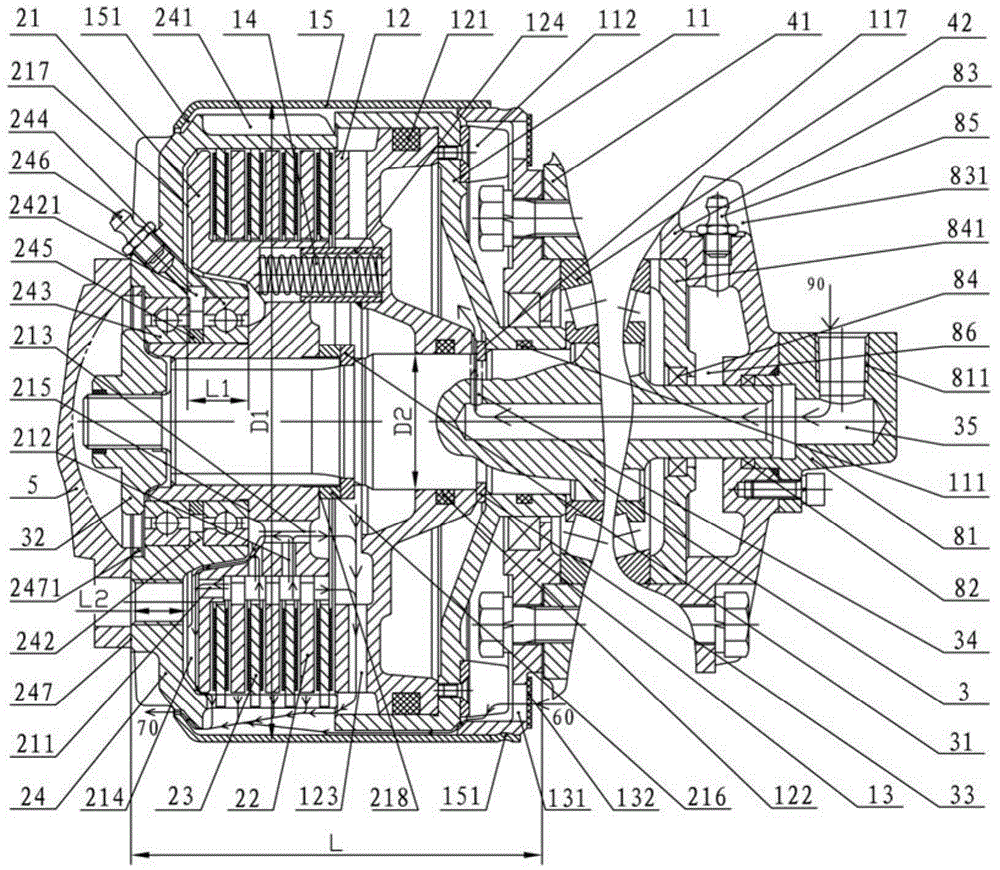

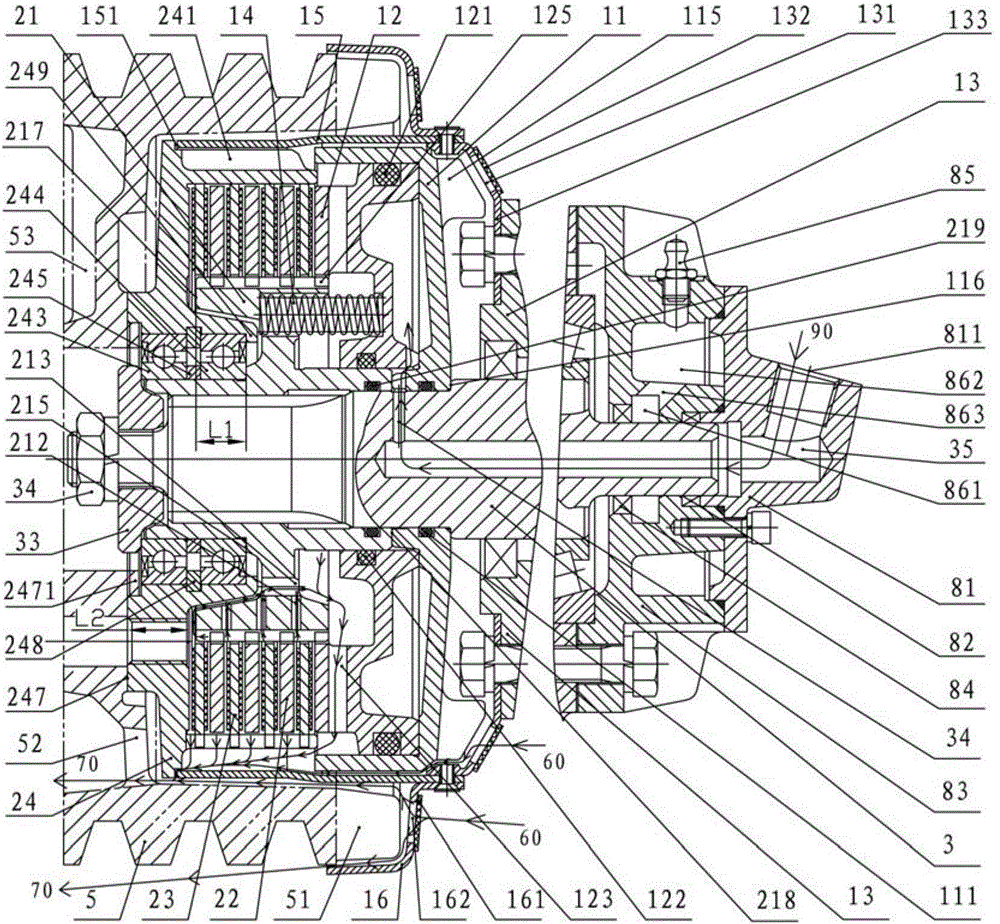

[0030] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0031] The invention discloses a pneumatic multi-disc friction clutch of a piston-cylinder rotary type, which is connected between a first transmission device and a second transmission device. shaft, wherein the control air pressure interface device is connected to the first end of the connecting shaft, the second transmission device is arranged on the second end of the connecting shaft, and the connecting shaft is from the first end to the The direction of the second end runs through the first transmission device, the front structure and the rear structure in sequence, the front structure includes a guide seat, a piston cylinder, a piston and a return spring, and the rear structure includes an inner friction plate seat, a plurality of inner friction plates, a plurality of outer friction plates and an outer friction plate con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com