Display substrate and manufacturing method therefor and display device

A display substrate and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of light leakage, light color, light output rate and color purity of OLED display devices, and optoelectronic properties of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

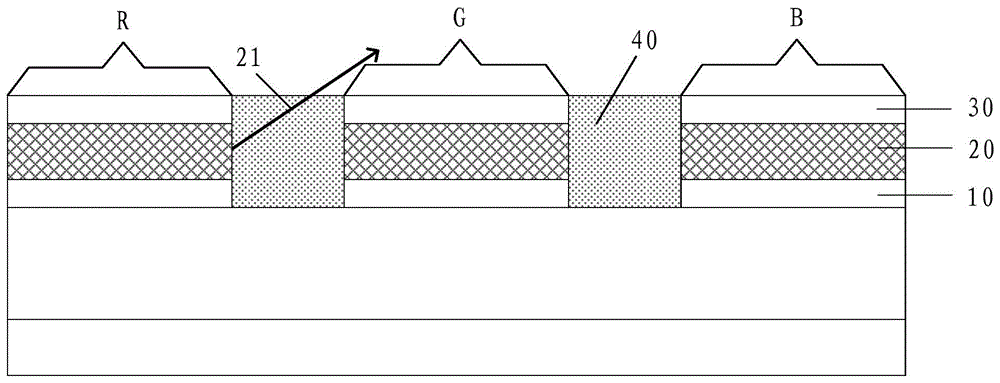

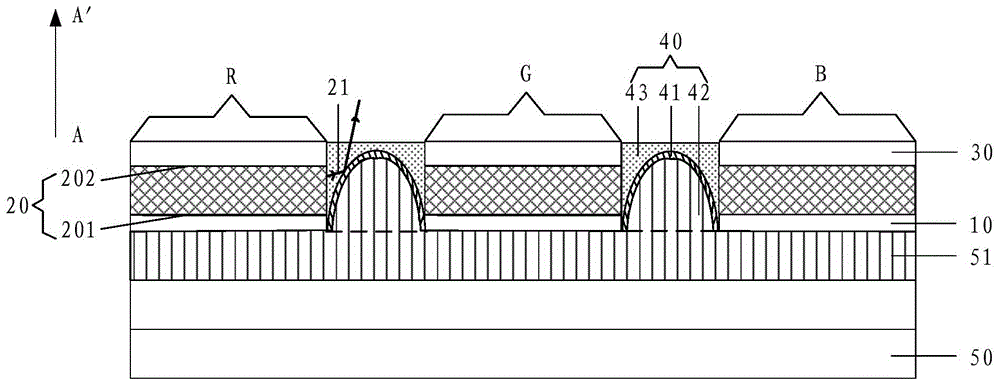

[0023] An embodiment of the present invention provides a display substrate, referring to Figure 2-3 As shown, the display substrate includes: a transparent substrate 50, a pixel defining layer 40 formed on the transparent substrate 50, and a light emitting layer 20 located in the sub-pixel region defined by the pixel defining layer 40; the pixel defining layer 40 includes: a reflective Layer 41, the reflective layer 41 is convex toward the light-emitting side of the display substrate, and is used to reflect the light emitted from the light-emitting layer to the reflective layer to the light-emitting side of the display substrate; in the area where the pixel defining layer is located, from the reflective layer to the display substrate The light-emitting side part is transparent.

[0024] In the above display substrate, the embodiment of the present invention does not limit the material of the light-emitting layer, for example, the material of the light-emitting layer may be an...

Embodiment 2

[0033] An embodiment of the present invention provides a display substrate, referring to figure 2 As shown, the display substrate includes: a transparent substrate 50, a pixel defining layer 40 formed on the transparent substrate 50, and a light emitting layer 20 located in the sub-pixel region defined by the pixel defining layer 40; the pixel defining layer 40 includes: a reflective Layer 41, the reflective layer 41 is convex toward the light-emitting side of the display substrate, and is used to reflect the light emitted from the light-emitting layer to the reflective layer to the light-emitting side of the display substrate; the pixel defining layer 40 also includes: The projection 42, the reflective layer 41 covers all or part of the projection 42, and the first transparent portion 43 located on the reflective layer 41; the light-emitting side of the display substrate is the surface of the display substrate away from the transparent substrate.

[0034] In the above displa...

Embodiment 3

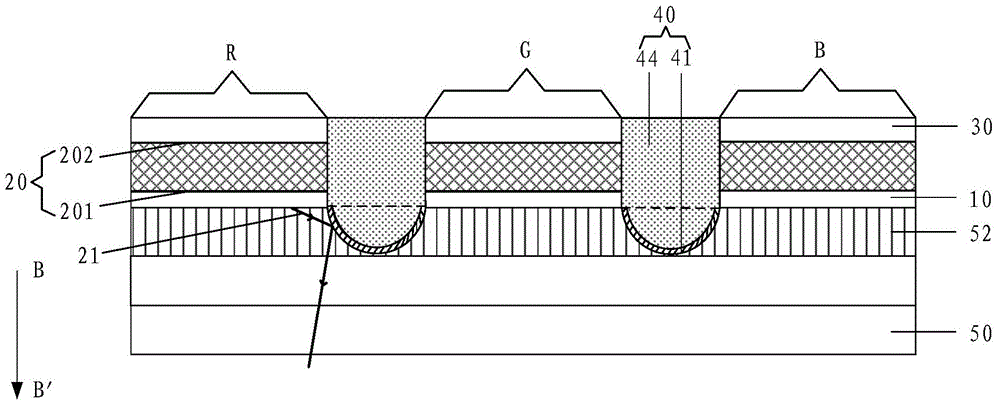

[0043] An embodiment of the present invention provides a display substrate, referring to image 3 As shown, the display substrate includes: a transparent substrate 50, a pixel defining layer 40 formed on the transparent substrate 50, and a light emitting layer 20 located in the sub-pixel region defined by the pixel defining layer 40; the pixel defining layer 40 includes: a reflective Layer 41, the reflective layer 41 is convex toward the light-emitting side of the display substrate, and is used to reflect the light emitted from the light-emitting layer to the reflective layer to the light-emitting side of the display substrate; the display substrate also includes a second transparent layer on the transparent substrate 50 layer 52, the second transparent layer 52 is formed with a groove in the area where the pixel defining layer 40 is located, and the reflective layer 41 covers all or part of the groove; the pixel defining layer 40 also includes: a second transparent portion 44 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com