Communication connector

A connector and electrical connection technology, applied in the direction of connection, parts of connection devices, and the manufacture of contact boxes/bases, etc., can solve problems such as residual glue in finished products and affecting connection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

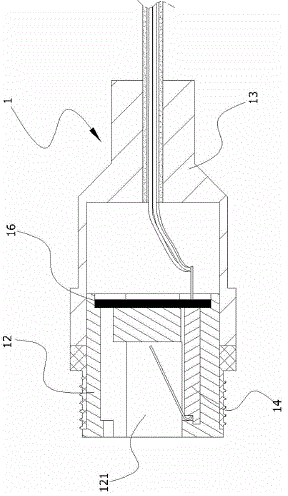

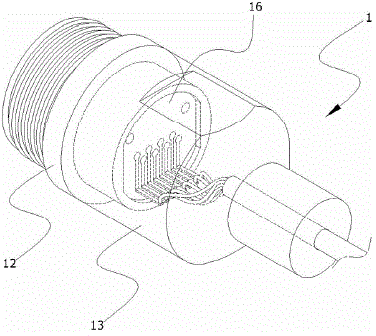

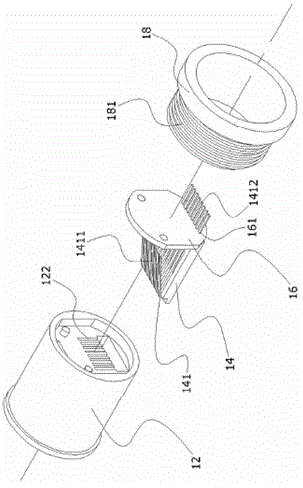

[0021] see figure 1 , as shown in the figure is a schematic cross-sectional view of the application, as shown in the figure, the communication connector 1 is mainly pre-assembled by part of the structure, and then the other part is injected into the mold to make a complete physical system The finished product, as shown in the figure, its pre-configurable part mainly includes a main base body 12, a pin seat 14, and a stopper 16, and the part injected into the mold is coated on the main base body 12 Covering part 13 of the rear end; please refer to figure 2 , shown in the figure is the three-dimensional appearance view (1) of the application, after the communication connector 1 is manufactured, it will be as shown in this figure; please refer to image 3 , shown in the figure is a schematic diagram of the component combination of the present application (1). As shown in the figure, before the pre-configuration operation is carried out, the stitch base 14 has several stitches 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com