Cleaning installation for a continuous belt consisting of metal, and a strip caster installation comprising such a cleaning installation

A metal belt and endless belt technology, applied in metal processing equipment, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as economic loss of downtime, improve economy, improve product quality, simplify cleaning and The effect of maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] First of all, it should be ensured that in the differently described embodiments, the same parts have the same reference signs or the same component designations, and that the disclosure content contained in the entire description can be transferred to on the same part of the name. The positions selected here in the description, such as top, bottom, side, etc., relate to the currently described and shown figures and can be transferred to the new position if the position changes. Furthermore, individual features or combinations of features of the various exemplary embodiments shown or described can themselves constitute independent, inventive or inventive solutions.

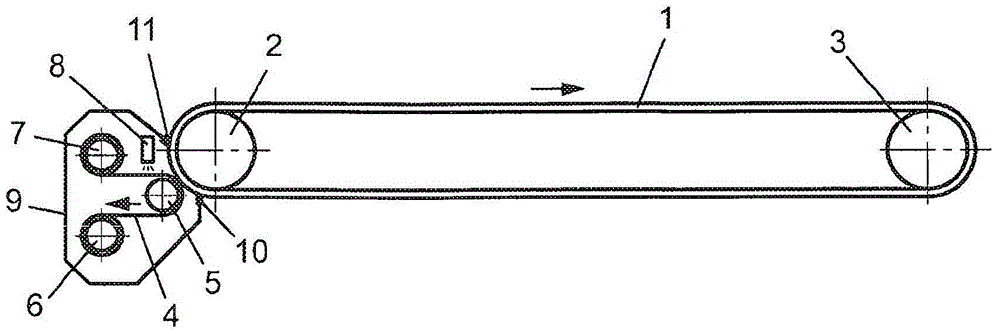

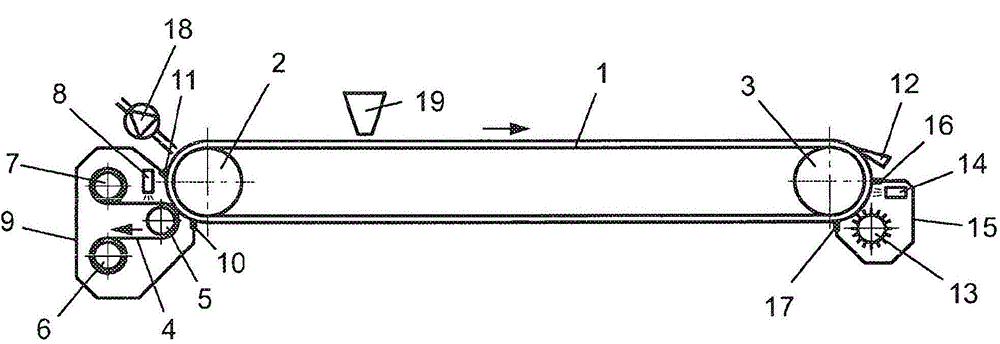

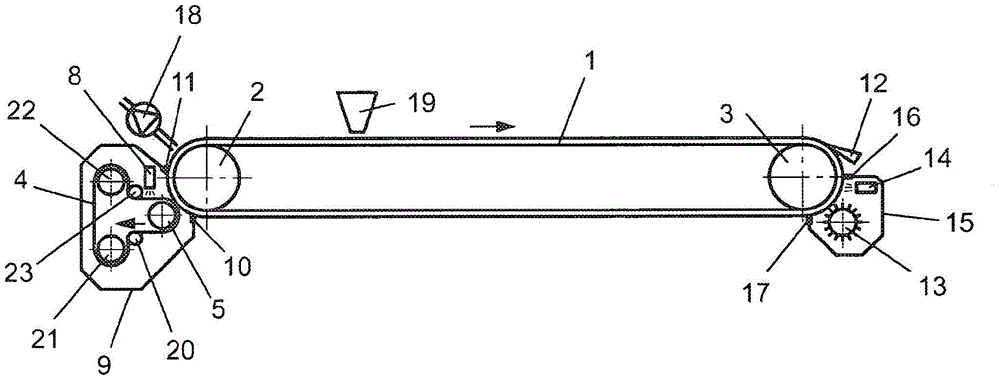

[0039] figure 1 A schematically shown first arrangement system is shown, which comprises an endless belt 1 made of metal and two deflection rollers 2 , 3 around which the endless belt 1 is guided. The arrangement system also comprises first drive means provided for moving the metal strip 1 . In the exemp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com