Slip ring arrangement

A technology of slip ring and ring, applied in the field of slip ring arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

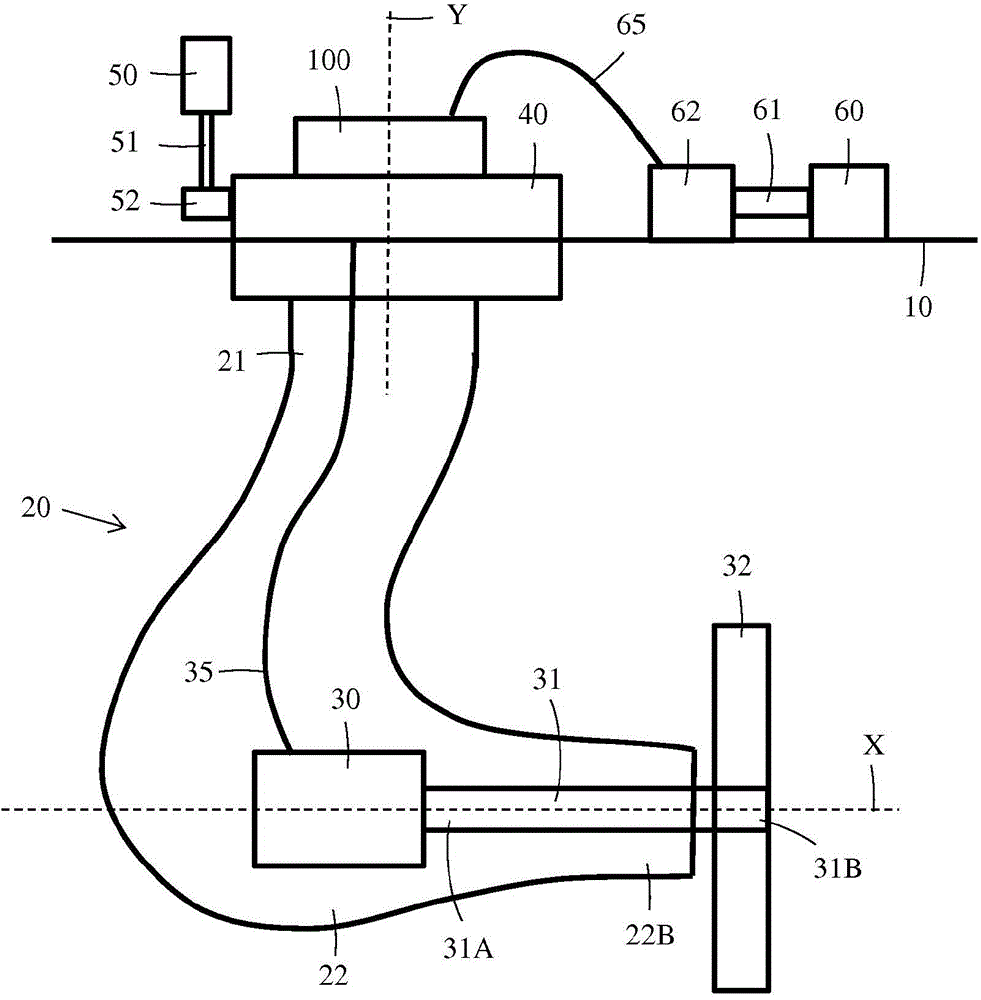

[0030] figure 1 A vertical section is shown of a compartment arrangement in a ship to which the slip ring arrangement according to the invention can be applied. The compartment arrangement comprises a hollow compartment 20 having an upper part 21 and a lower part 22 . The compartment 20 is attached at the hull 10 of the ship from the upper part 21 . The lower part 22 of the compartment 20 forms a longitudinal compartment comprising a first electric motor 30 and a first shaft 31 . A first end 31A of the first shaft 31 is connected to the electric motor 30 and a second end 31B of the first shaft 31 protrudes from the rear end 22B of the lower part 22 of the compartment 20 . The pusher 32 is connected to the second outer end 31B of the first shaft 31 . The axis X of the first shaft 31 forms a shaft line. The compartment 20 is rotatably attached to the vessel 10 via the upper part 21 so that the compartment 20 can be turned 360 degrees around a vertical central axis Y. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com