Stamping rice ball machine

A punching and rice ball technology, which is applied in the fields of food forming, food science, and application, can solve the problems of easy gripping, unsecured safety, and no protection measures, and achieves the effect of uniform quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

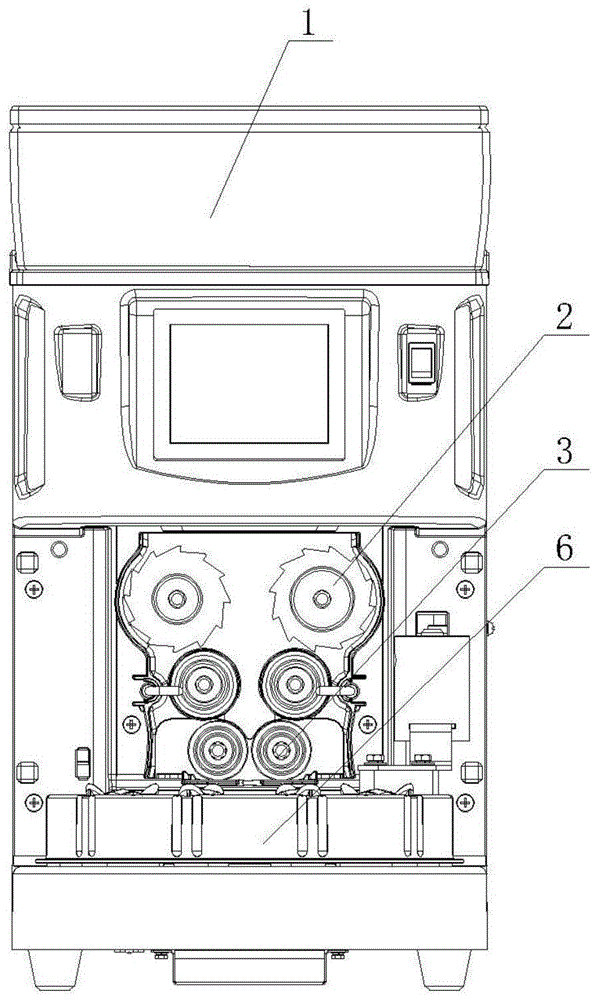

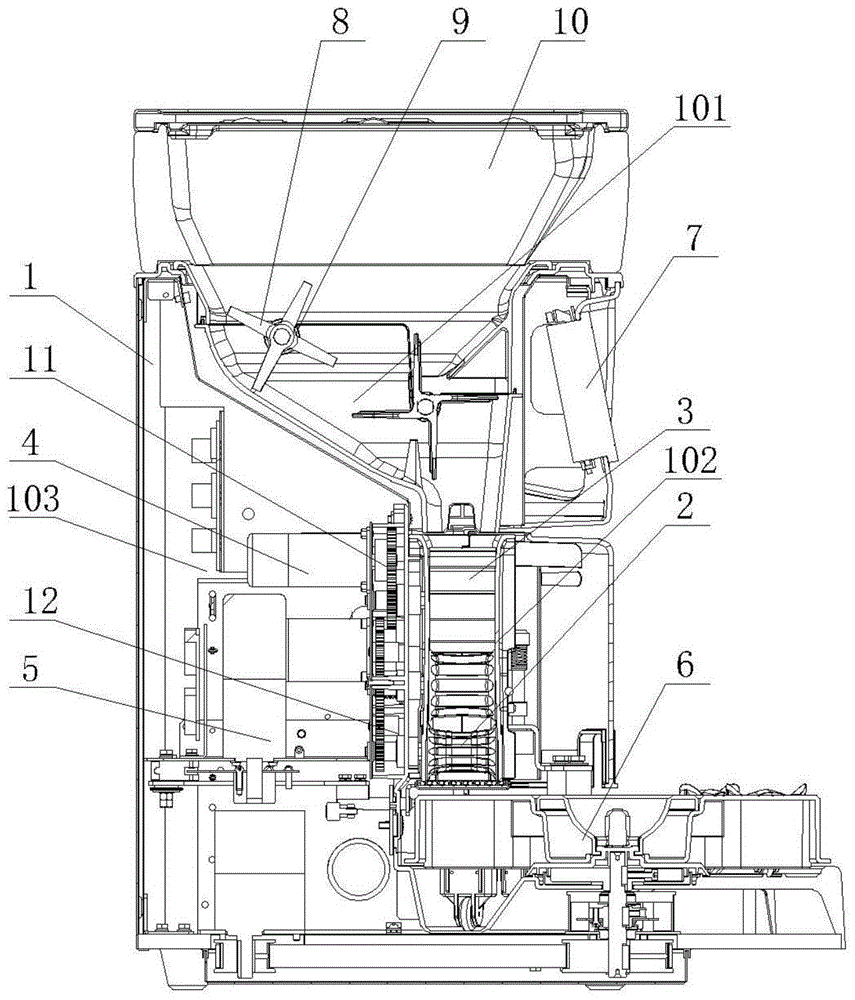

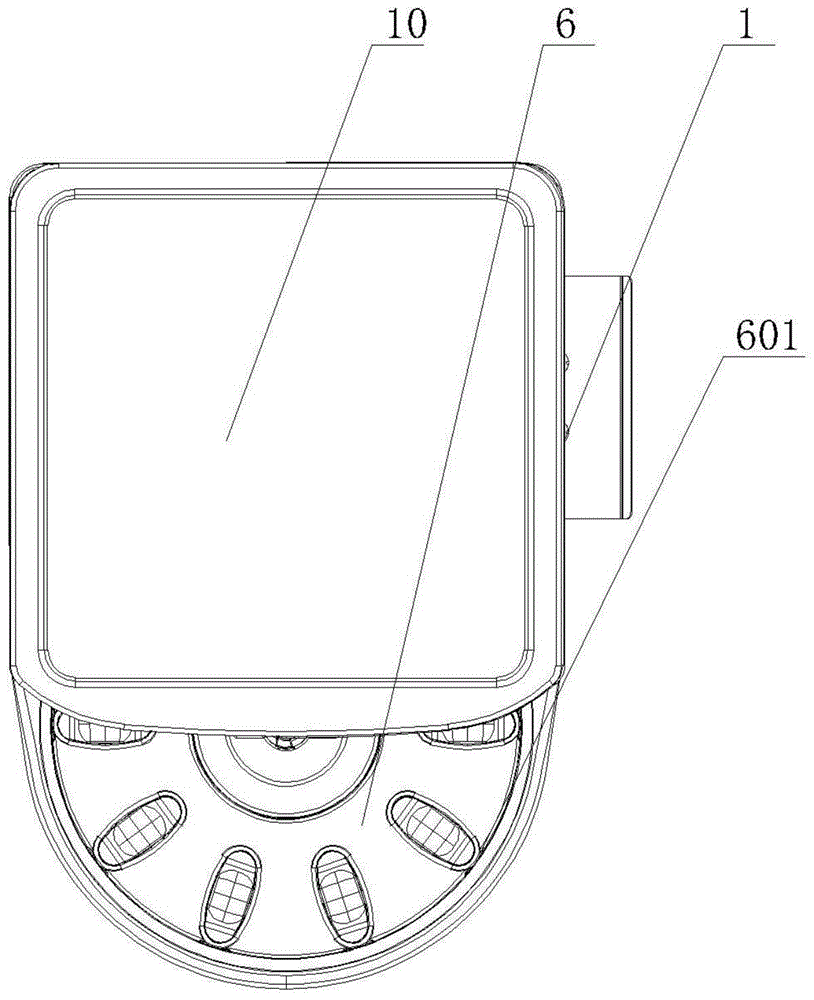

[0021] Such as Figure 1 to Figure 4 As shown, the stamping rice ball machine of this embodiment includes a casing 1, an extrusion wheel set 2, a feed roller set 3, a feed motor 4, an extrusion motor 5, a turntable indexing device 6, a material partition plate 7, and a turning paddle 8 , a second motor 9, a shell cover 10, a second induction switch and a magnet, the casing 1 is provided with a raw material chamber 101, an extrusion chamber 102 and a transmission chamber 103, and the raw material chamber 101 is located at the top of the casing 1 and There is a feed port, the extrusion chamber 102 and the transmission chamber 103 are located at the bottom of the casing 1, the extrusion chamber 102 communicates with the raw material chamber 101, and the bottom of the extrusion chamber 102 is provided with a discharge port, so The two extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com