Full-automatic imitation handmade pancake machine

A manual and fully automatic technology, applied in the direction of baking pancakes, baking, oil/fat baking, etc., can solve the problems of inability to guarantee the taste of pancakes, inefficiency, time-consuming and laborious, and achieve the preservation of physical properties and feel, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

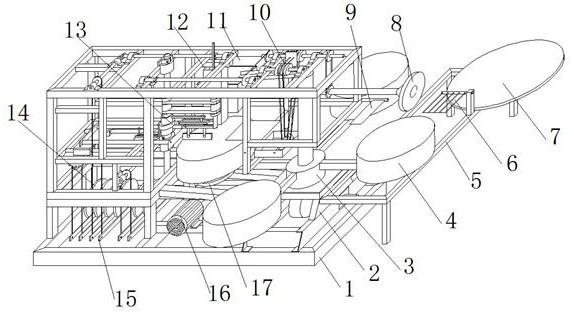

[0019] see figure 1 , in the embodiment of the present invention, a kind of full-automatic imitation manual pancake machine comprises frame 1, power mechanism, intermittent divider 2, cam assembly 14, heating plate 4, spread pancake device 13, batter unloading device 12, batter Recovery device 10, pancake stacking device 9 and control panel, the power mechanism is installed on the frame 1, the power mechanism is installed on the motor 16 and reducer, the motor 16 is connected with the reducer through the clutch 17, the intermittent The divider 2 and the cam assembly 14 are installed on the frame 1, the intermittent divider 2 and the cam assembly 15 are connected with the power mechanism, the intermittent turntable 3 is installed on the intermittent divider 2, and several The heating plate 4, the cam assembly 14 is connected with a swing link mechanism 15, and the frame 1 is equipped with a pancake spreading device 13, a batter cutting device 12, a batter recovery device 10, a ...

Embodiment 2

[0023] On the basis of the first embodiment, the batter feeding device 10 includes a hopper, and the hopper is provided with a hopper valve.

[0024] Workflow: The intermittent divider 2 rotates, driving the intermittent turntable 3 to turn the heating plate 4 to the designated working position, the hopper valve is opened, and a certain amount of batter is pressed out by the plunger inside the hopper, the hopper valve is closed, the batter falls on the heating plate 4, and the clutch 17 is engaged, the heating plate 4 starts to rotate, and the pancake spreading device 13 falls onto the heating plate 4, and begins to spread pancakes. After the pancakes are spread for a circle, the clutch 17 disengages, the heating plate 4 stops rotating, and the pancake spreading device 13 rises, and the batter The push plate pushes the remaining batter onto the paste receiving plate, and the batter recovery device 10 recycles the batter into the hopper. The intermittent turntable 3 continues t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com