Magnetic bar cleanser

The technology of a washer and a magnetic rod is applied in the directions of chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., which can solve problems such as low construction efficiency, and achieve a lightweight structure, convenient and fast cleaning operations, and easy to carry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

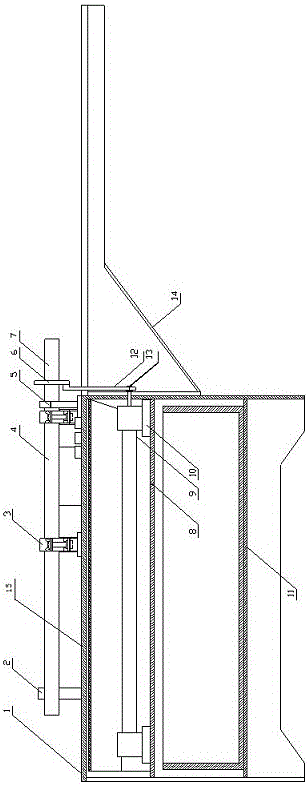

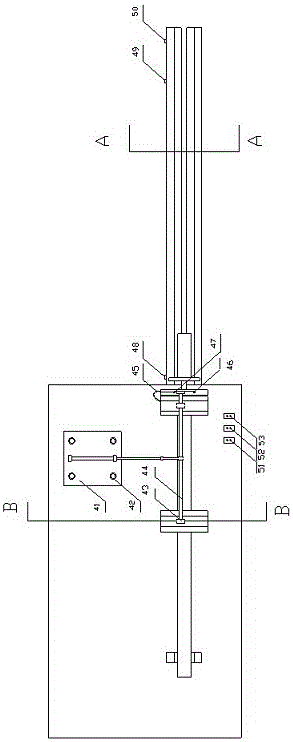

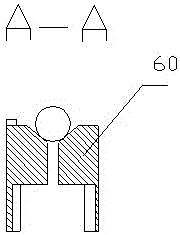

[0020] Such as figure 1 , figure 2 , image 3 As shown, a magnetic rod cleaner includes a magnetic rod cleaner body 1, the magnetic rod cleaner body 1 is provided with a pneumatic valve table 34 and a cleaning unit 3 connected to the pneumatic valve table 34 through a pipeline 36, a blower Sweeping unit 5, the first cylinder 20, the second cylinder 9, the cleaning unit 3 is a crank connecting rod structure, including a fixed semi-circular sealing seat 26, a swinging semi-circular sealing seat 25, a short connecting rod 22, a long The connecting rod 44, the fixed semi-circular seal seat 26 is connected to the swing center of the swing semi-circular seal seat 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com