Gantry type slab-bottom flat cutting machine

A gantry-type, flat machine technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of different shapes of block bottoms, occupying space, difficult to handle the bottom of the board, etc., to achieve compact structure and good rigidity , the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

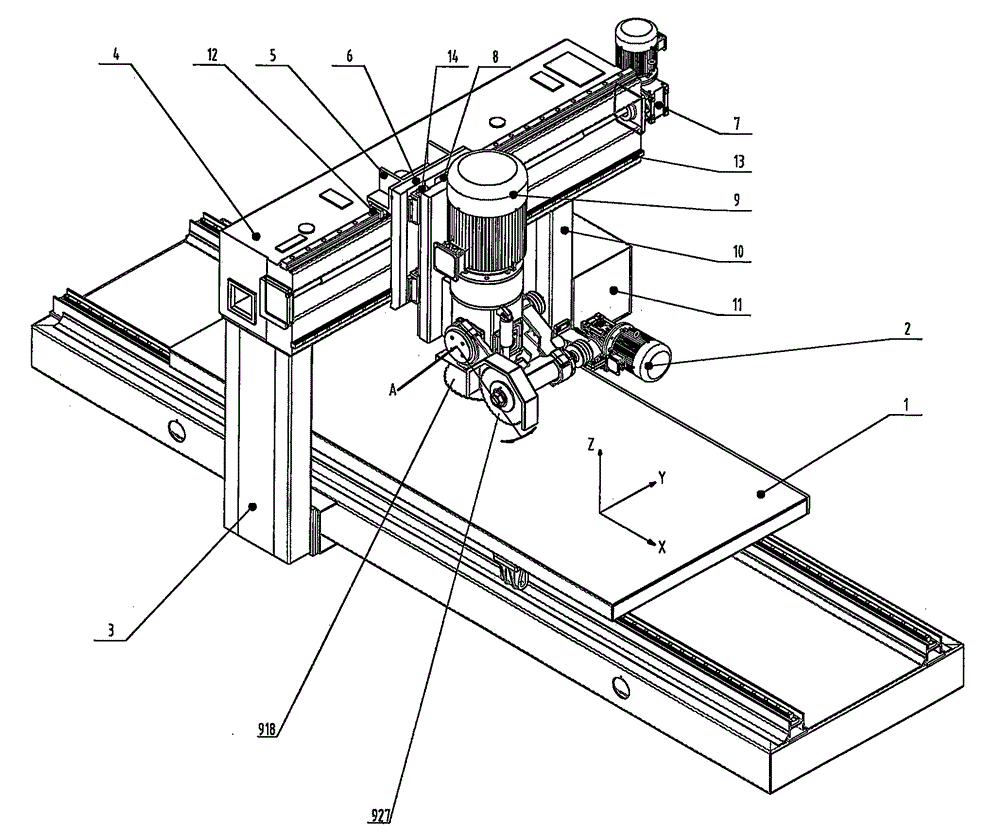

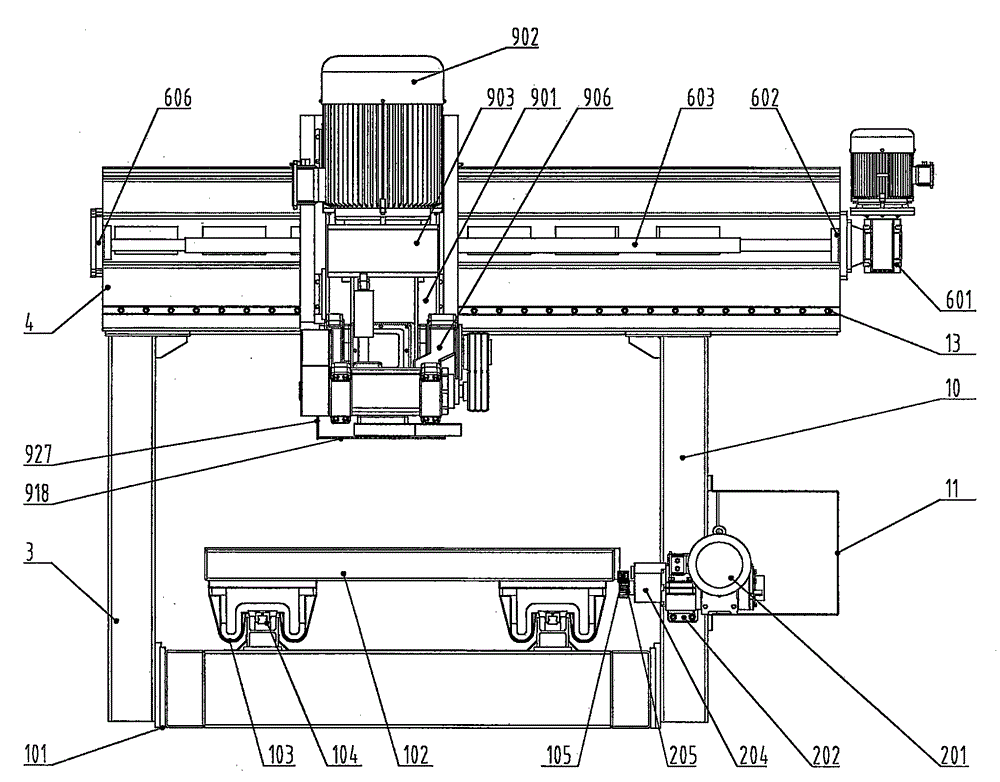

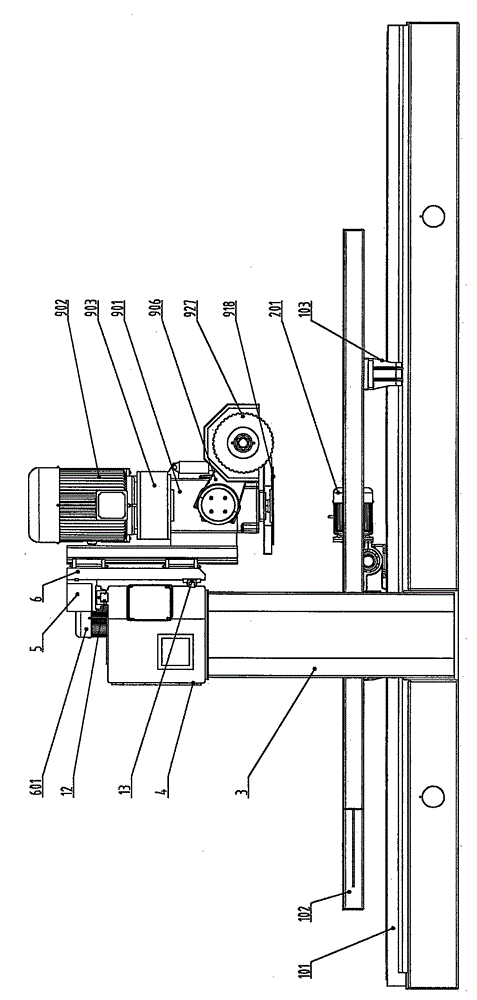

[0071] A gantry type plate bottom cutting machine, according to Figure 1-4 As shown, it includes: the main base 101, the left column 3, the right column 10 and the beam 4 are fixed as a gantry structure, a translation workbench 102, and a power head assembly 9, and the power head assembly 9 is fixed on the lifting bracket 901, The lifting bracket 901 is connected to the cross slide 6 through the linear guide rail pair 14, and is driven by the hydraulic mechanism 8 to slide and cooperate with the cross slide 6 up and down, that is, the Z axis; the cross slide 6 is driven by the cross slide drive device 7 along the cross beam 4, that is, the Y axis Sliding fit, the power head assembly 9 is connected to the flat cutting saw blade 908 through the flat cutting main shaft 911; the power head assembly 9 drives the cutting saw blade 927 through the swing transmission device for cutting the saw blade; at the same time, the cutting of the swing transmission device for cutting the saw bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com