An installation structure of a wheel disc brake and a bogie using the installation structure

A technology for installation structure and brakes, which is applied in the field of bogies, can solve problems such as unfavorable bogie internal equipment layout and design, can not relieve the pressure of urban transportation, and cannot meet the needs of subway passenger capacity, etc., to achieve compact structure, Reduced welding area and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

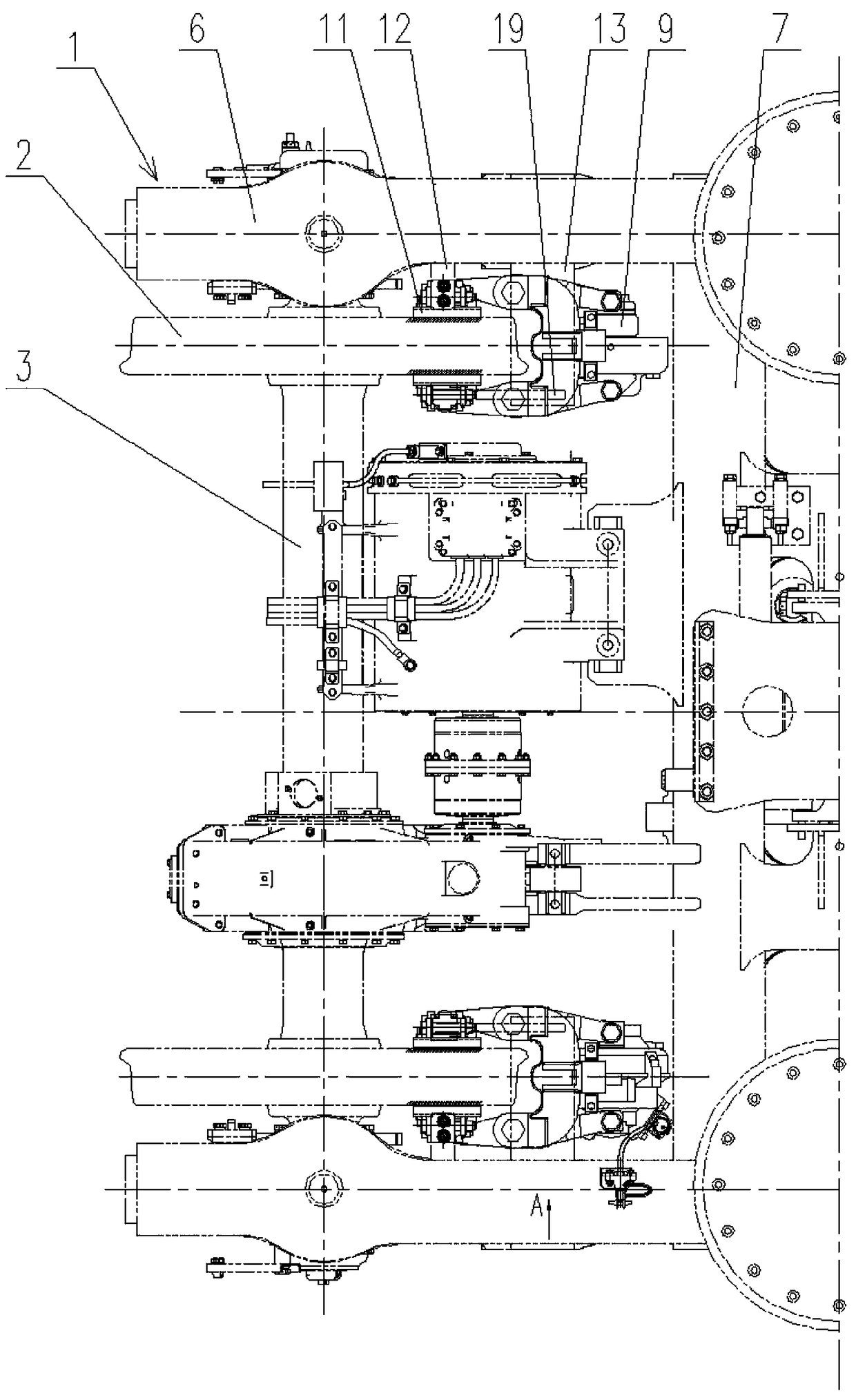

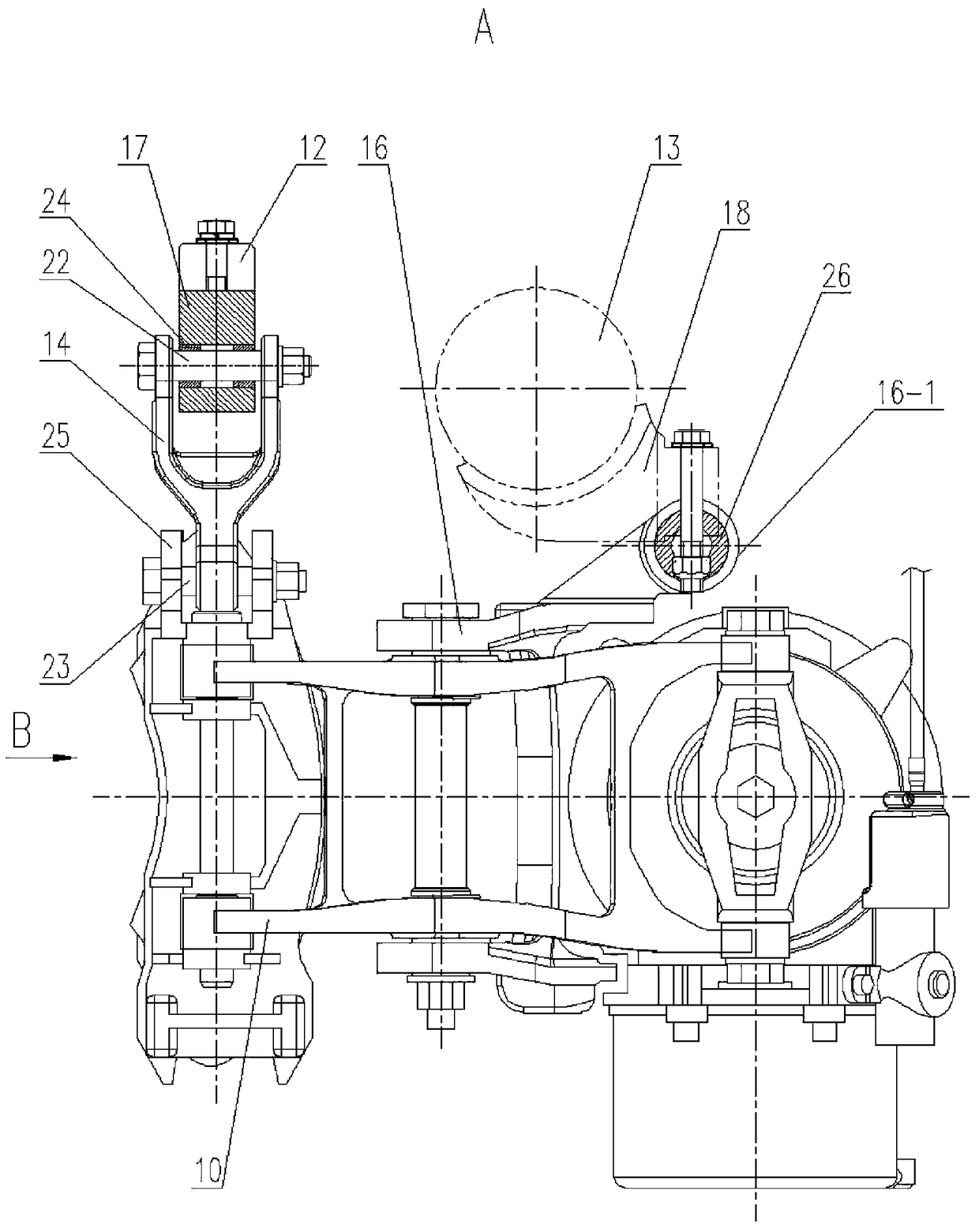

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0032] For the convenience of readers, figure 1 and image 3 The second connection part 19 is omitted in the Figure 4 The round steel pipe and the second connection part 19 of the rear mounting seat 13 are omitted in the Figure 6 The schematic part of the second suspension point 15 is added in .

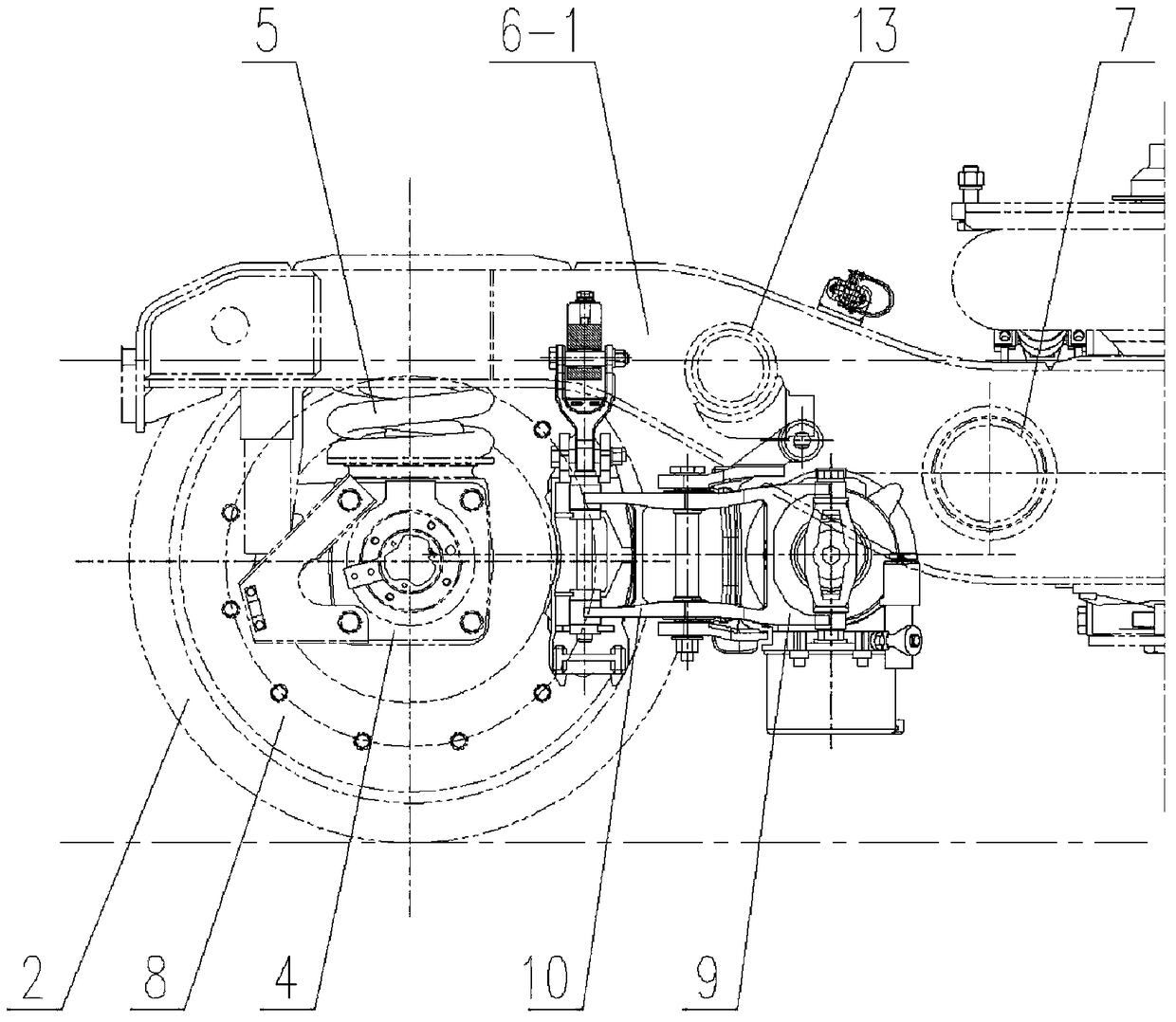

[0033] Such as Figure 1 to Figure 4 As shown, a disc brake installation structure includes a disc brake 9, a frame 1 and a wheel set. The frame 1 includes side beams 6 on both sides, and a cross beam 7 is set in the middle of the side beams 6 to fix the side beams 6 on both sides. . The wheel set includes an axle 3 and wheels 2 at both ends of the axle 3 , and an axle box 4 is arranged outside the wheel 2 , and the axle box 4 is fixedly connected to the side beam 6 through a series of suspension devices 5 .

[0034] Both sides of the wheel 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com