Aircraft carrier ejector

A technology for catapults and aircraft carriers, applied in the direction of launching/dragging transmissions, etc., can solve problems such as huge power consumption, complex technologies or processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

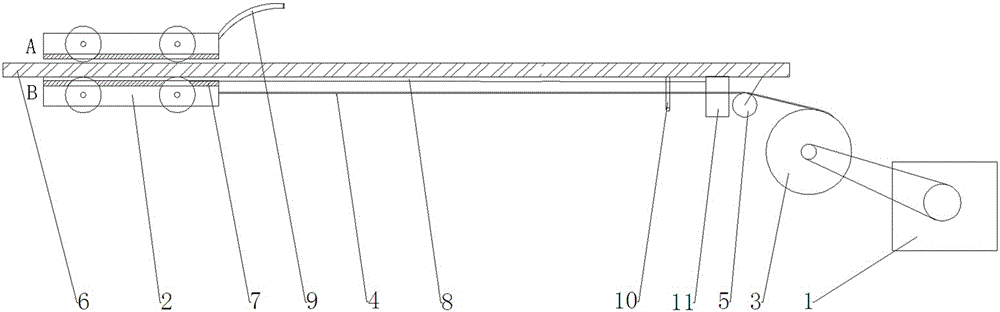

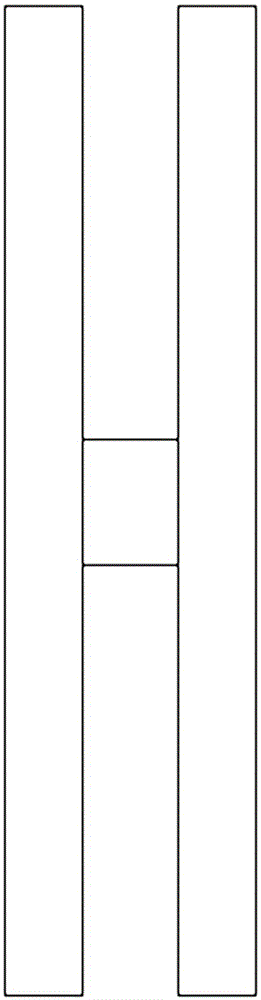

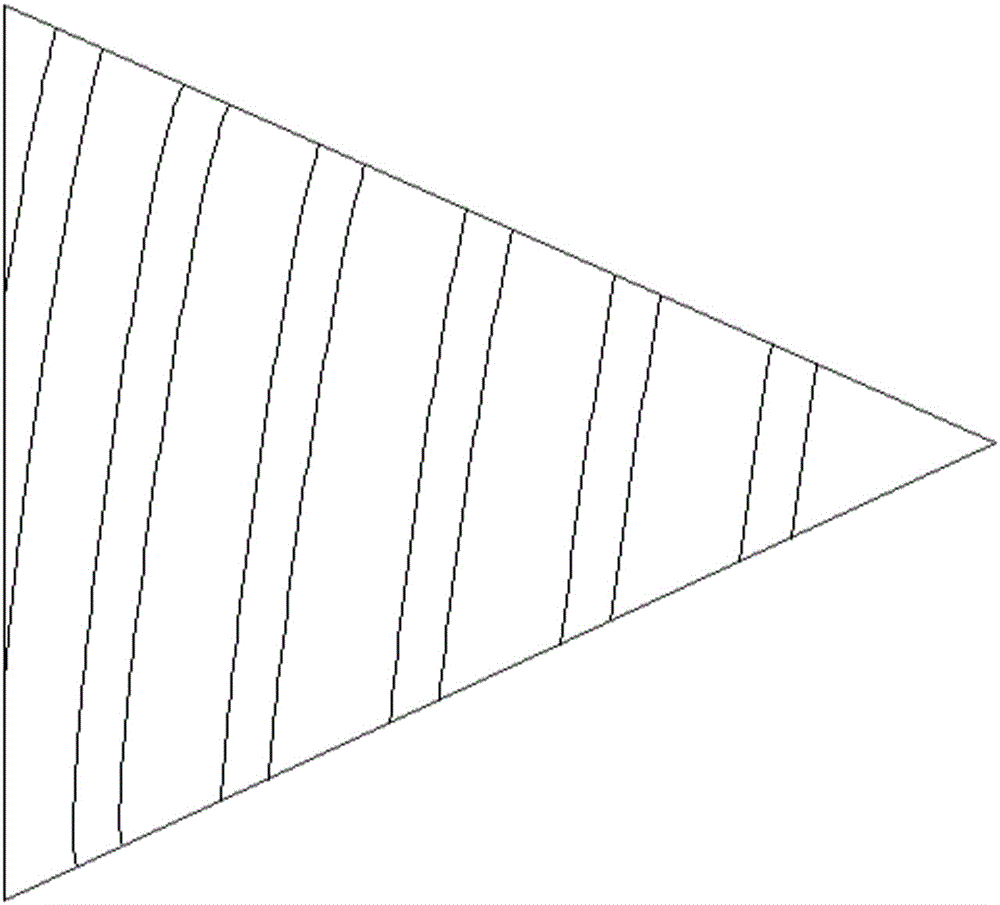

[0016] Such as figure 1 As shown, the aircraft carrier catapult includes a diesel unit 1 and a magnetic vehicle 2, the diesel unit 1 is connected to the input shaft of the acceleration wheel 3 through a belt, one end of the traction rope 4 is connected to the magnetic vehicle 2, and the other end passes through the fixed pulley 5 and is wound on the acceleration wheel 3, the magnetic car includes A car and B car, A car is located on the deck 6, B car is located under the deck, the lower surface of the A car and the upper surface of the B car are all provided with strong magnets 7, and a magnet 7 is provided between the B car and the deck. There are track grooves 8, two thrust bushings 9 are provided at the end of car A, a traction rope fixing device is provided at the end of car B, and a detection contact 10 is provided near the fixed pulley under the deck, and the detection contact 10 is connected to the controller for control For the diesel engine switch, a buffer 11 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com