A falling film evaporation process and device for coking sewage desorption wastewater

A technology of coking sewage and falling film evaporation, applied in the direction of heating water/sewage treatment, etc., can solve the problems of low heat utilization rate, hindering popularization and application, complicated system operation, etc., and achieve high heat utilization rate, low input cost, and process Reasonably compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

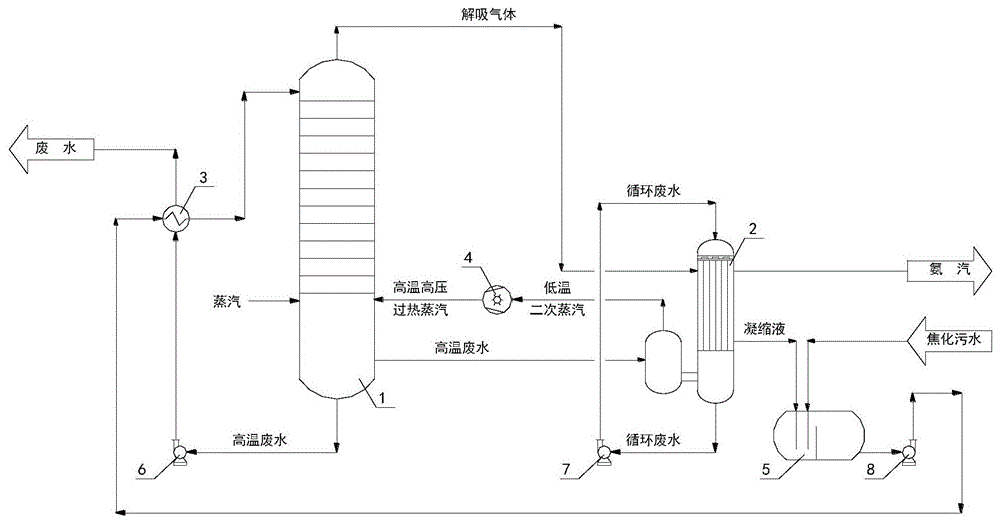

[0035] The coking sewage enters the raw sewage tank 5, and is pumped out by the raw sewage pump 8 to send the sewage / wastewater heat exchanger 3 to exchange heat with the high-temperature waste water and raise the temperature to 97°C, then send it to the upper part of the desorption tower 1, and contact with the rising steam in the tower countercurrently, Desorb the NH contained in it by heating and stripping 3 、H 2 S, HCN and other components.

[0036] The temperature of the high-temperature wastewater obtained after desorption is 105°C. Most of the high-temperature wastewater is sent to the biochemical process for further treatment through the wastewater / wastewater heat exchanger 3 through the wastewater / wastewater heat exchanger 3, and then sent to the biochemical process for further treatment. A small part of the high-temperature wastewater enters the separation chamber of the falling film evaporator 2. The circulating wastewater at the bottom of the falling film evaporator...

Embodiment 2

[0040] The coking sewage enters the raw sewage tank 5, and is pumped out by the raw sewage pump 8 to send the sewage / wastewater heat exchanger 3 to exchange heat with high-temperature waste water and raise the temperature to 98°C. Desorb the NH contained in it by heating and stripping 3 、H 2 S, HCN and other components.

[0041] The temperature of the high-temperature wastewater obtained after desorption is 106°C. Most of the waste water is sent to the biochemical process for further treatment after the waste water pump 6 passes through the sewage / waste water heat exchanger 3 to exchange heat with the coking sewage. A small part of the high-temperature wastewater enters the separation chamber of the falling film evaporator 2. The circulating wastewater at the bottom of the falling film evaporator 2 is sent to the liquid distribution device at the top of the evaporator 2 by the circulating wastewater pump 7 to form a uniform liquid film and enter the heating tube, and partiall...

Embodiment 3

[0045] The coking sewage enters the raw sewage tank 5, and is pumped out by the raw sewage pump 8 to send the sewage / wastewater heat exchanger 3 to exchange heat with the high-temperature waste water and raise the temperature to 106°C. Desorb the NH contained in it by heating and stripping 3 、H 2 S, HCN and other components.

[0046] The temperature of the high-temperature wastewater obtained after desorption is 114°C. Most of the waste water is sent to the biochemical process for further treatment after the waste water pump 6 passes through the sewage / waste water heat exchanger 3 to exchange heat with the coking sewage. A small part of the high-temperature wastewater enters the separation chamber of the falling film evaporator 2. The circulating wastewater at the bottom of the falling film evaporator 2 is sent to the liquid distribution device at the top of the evaporator 2 by the circulating wastewater pump 7 to form a uniform liquid film and enter the heating tube, and par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com