Dyeing method of cheese and the sealing lock used

A cheese and lock technology is applied in the field of the cheese dyeing method and the sealing lock used, which can solve the problems of increased energy consumption, dyeing quality problems, increased ineffective flow rate, etc. The effect of traffic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

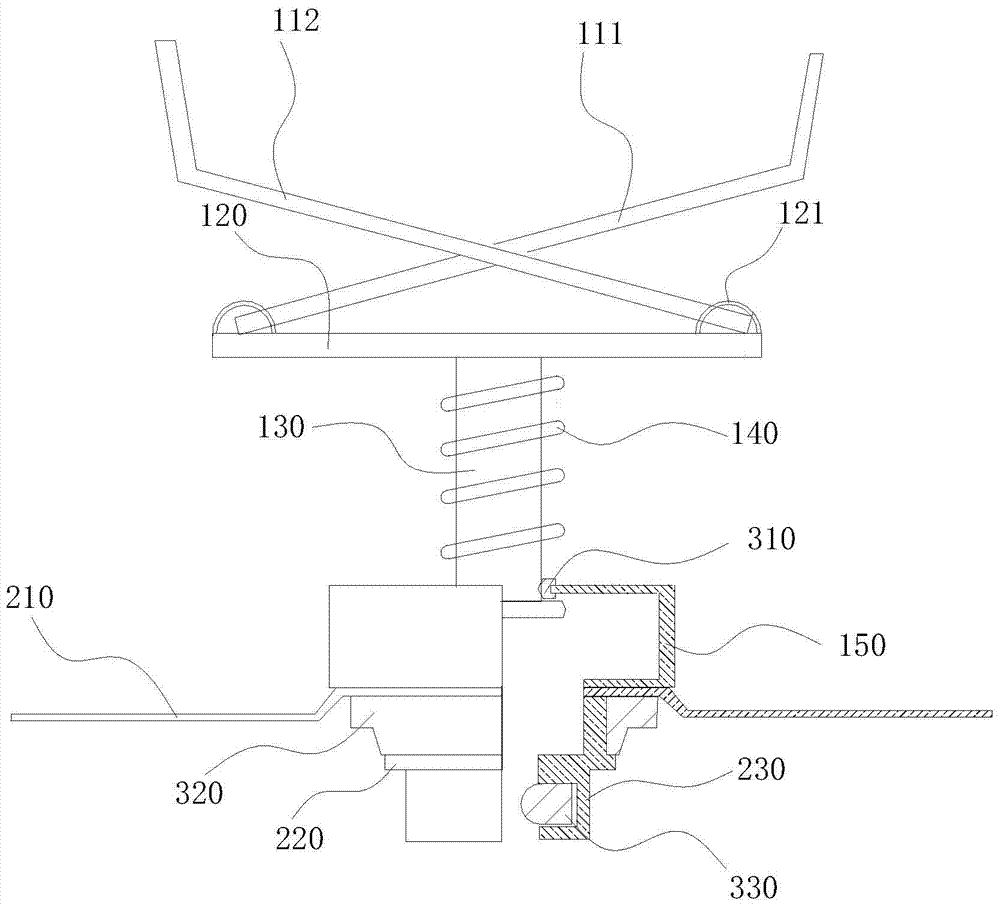

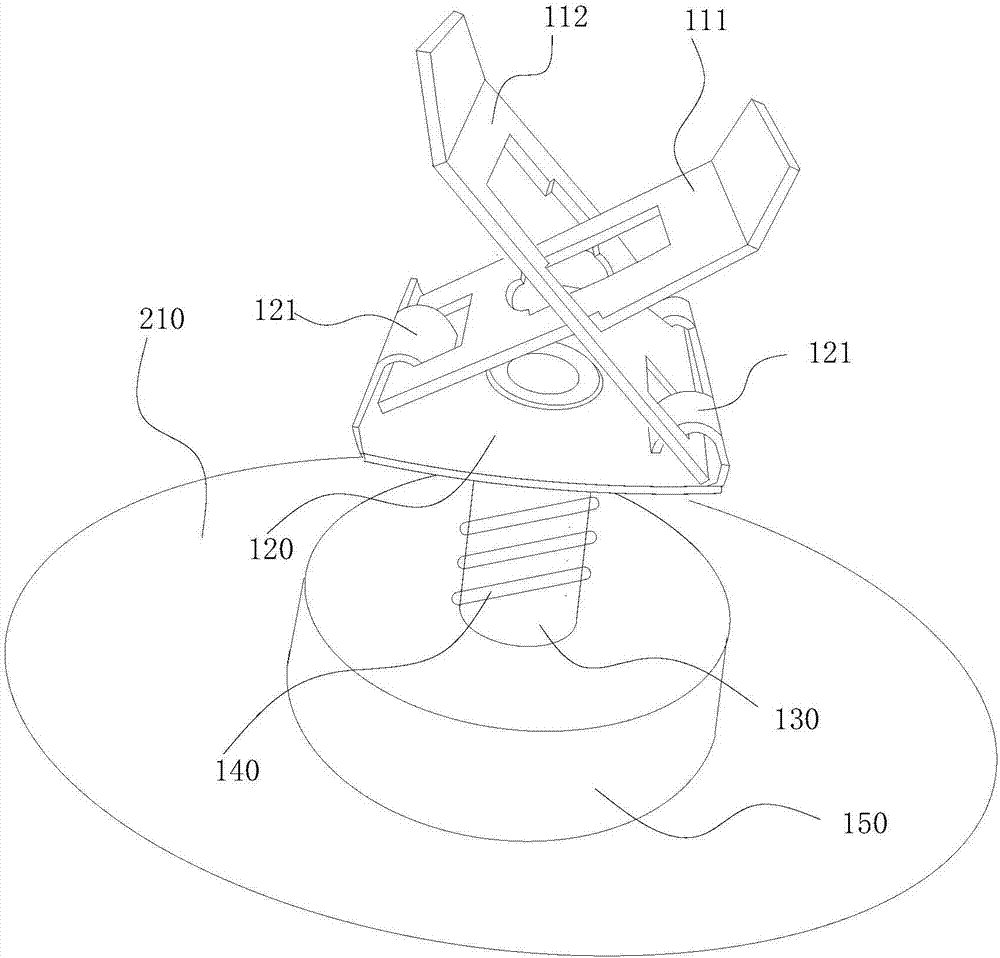

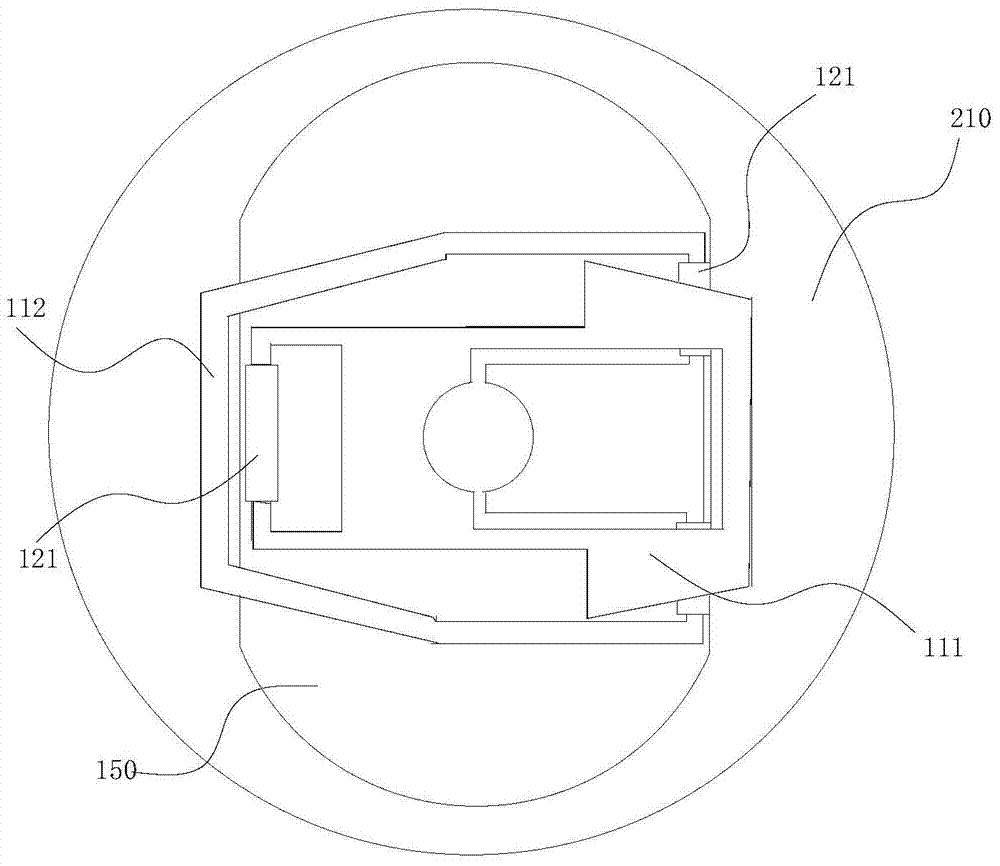

[0034] A sealing lock for cheese dyeing, such as figure 1 As shown, including: pressing device, sealing device and seal, wherein:

[0035] The pressing device includes a pressing buckle, a pressing plate 120 , a support column 130 , an elastic component 140 and a connecting piece 150 .

[0036] The pressing plate 120 is provided with a first through hole matching the supporting column 130, and the connecting piece 150 is provided with a second through hole matching the supporting column 130, and the supporting column 130 is a hollow tubular structure for use in To allow the central yarn rod to pass through, one end of the supporting column 130 is fixed in the first through hole, and the other end is inserted into the second through hole, the elastic member 140 is sleeved on the supporting column 130, and one end of the elastic member 140 is against the The other end leans against the connecting piece 150 on the pressing plate 120 . In this embodiment, in order to simplify th...

Embodiment 2

[0044] A kind of cheese dyeing method, adopts the sealed lock of embodiment 1, the scouring, bleaching and dyeing process in the production process is:

[0045] Loose tube→loading into cage→into cylinder to test pressure leakage→scouring and bleaching→dyeing→washing→fixing color and softening→out of cylinder

[0046] After loosening and packing the package yarn 400 according to the conventional technology, install the sealing lock head 100, and fasten the tooth edge of the pressing plate with the corresponding limit part on the center yarn rod, as shown in FIG. Figure 4 As shown, and pay attention to the cooperation between the sealing lock head and the bobbin and the central yarn rod, as shown in Figure 5 shown, make sure it is in place.

[0047] The process parameters of the dyeing vat are set as follows:

[0048] 1) The running direction of the main pump of the dye vat is a one-way cycle from inside to outside;

[0049] 2) The main pump speed range is 1200 rpm;

[005...

experiment example

[0053] According to the cheese dyeing method of embodiment 2, and adopt the dye vat of 7 rods 10 layers of traditional locking surface dish to carry out comparative experiment production simultaneously. What used in the experimental production is 80s / 2 yarn count, 70 single yarns weighing 1.6kg, a total of 112kg of pure cotton cheese.

[0054] Comparing the energy consumption and product quality in the production process, the results are as follows:

[0055] 1. Leakage test results

[0056]

[0057] It can be seen from the above table that the sealing lock head of Example 1 has reduced nearly 18% of the invalid flow in the cheese dyeing process.

[0058] 2. Analysis results of power consumption

[0059]

[0060] As can be seen from the above table, the sealing lock head of embodiment 1 produces cheese, which saves 3.5% of electric energy.

[0061] And, after adopting the method of embodiment 2 to dye, there is no problem of water flow breaking up or breaking the ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com