External pressing type flexible duct valve

A flexible pipeline and external pressure technology, applied in the field of pipeline valves, can solve problems such as high driving power and fluid pollution, achieve the effects of reducing manufacturing precision requirements, improving hygiene and safety quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

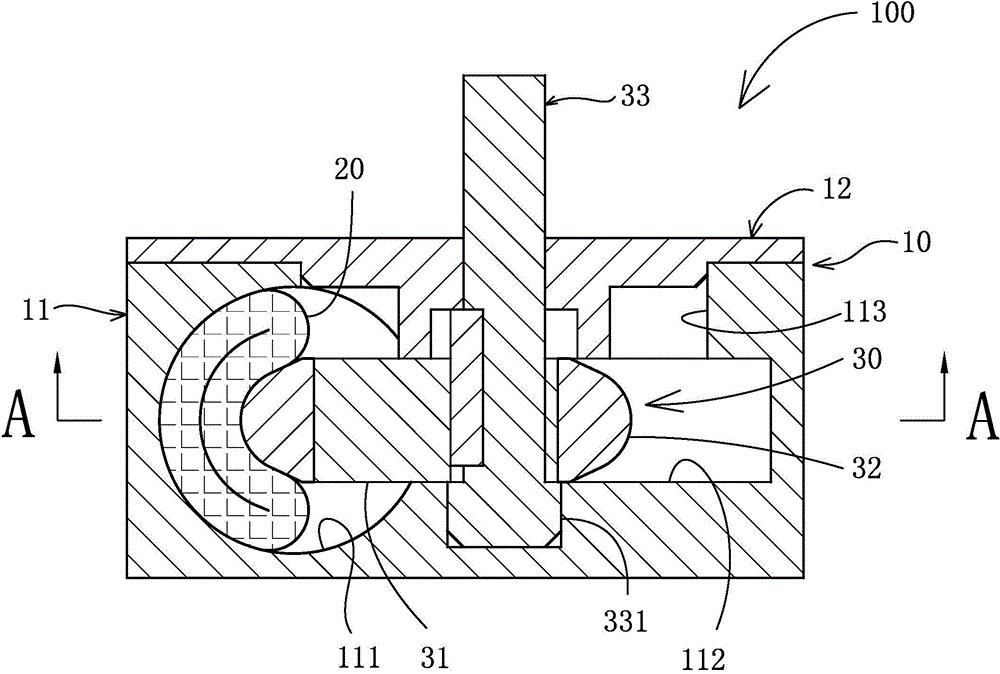

[0026] The external pressure flexible pipeline valve 100 of the present invention includes a valve body 10 , a flexible pipeline 20 passing through the valve body 10 and a rotating pressure applying component 30 disposed in the valve body 10 .

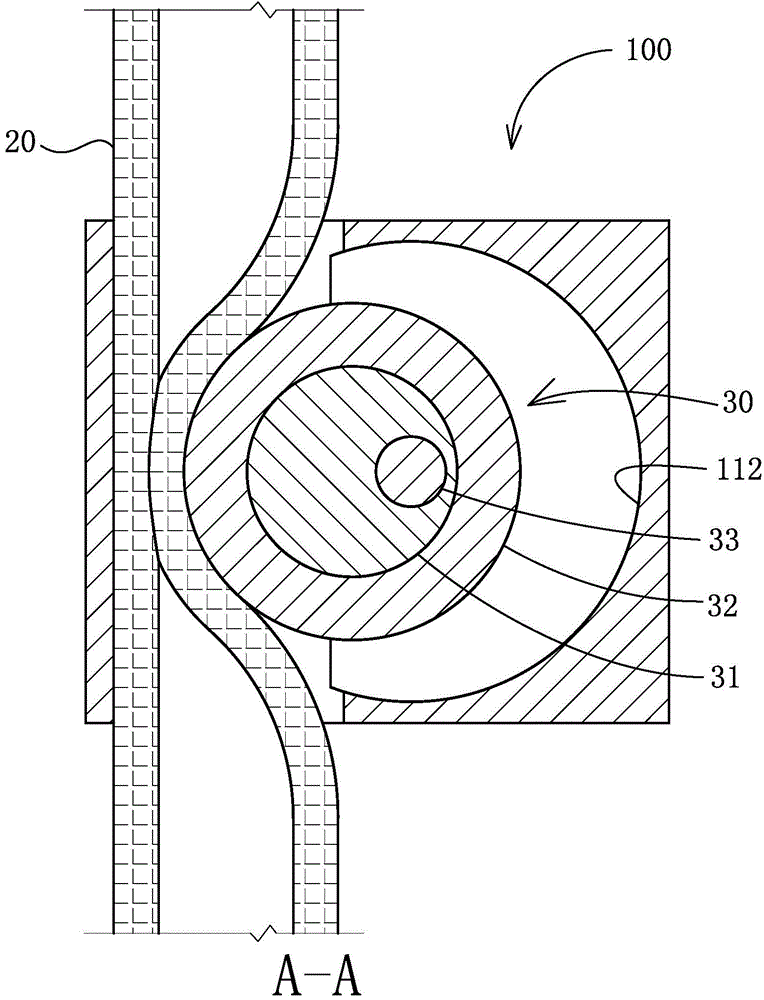

[0027] like Figure 5A ~ Figure 5C As shown, the valve body 10 includes a main body 11 and an end cover 12, the main body 11 is a rectangular block, and a cavity 112 is provided in the middle of the main body 11, as Figure 5B , the cavity 112 is a cylindrical cavity, the diameter and height of which are slightly larger than the diameter and height of the pressure roller 32 of the rotating pressure applying assembly, so that the pressure roller 32 can rotate freely therein. One side of the cavity is provided with a through hole 111, the through hole 111 communicates with the cavity 112, and the center line of the through hole 111 is perpendicular to the horizontal center line of the cavity 112, and the through hole 111 is used for pass...

Embodiment 2

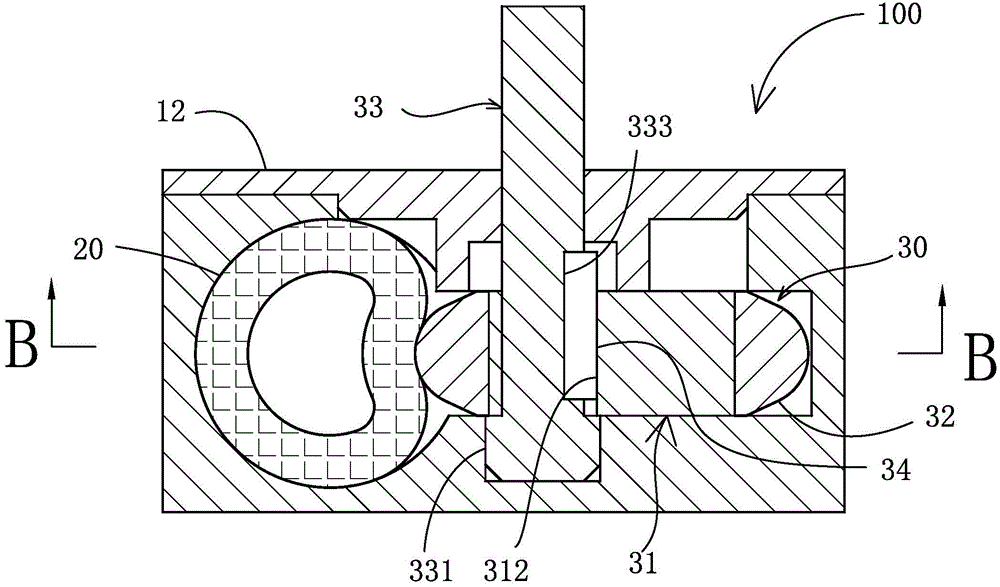

[0031] In this embodiment, the basic structure of the external pressure flexible pipe valve 100 is the same as that of Embodiment 1, the difference is that two sets of flexible pipes 20 and two sets of rotating pressure applying components 30 are arranged in the valve body 10 to form two sets of linkages. structure.

[0032] like Figure 8A ~ Figure 8C and Figure 9 As shown, the valve body 10 is axially provided with two through-holes 111 for piercing flexible pipes and a cylindrical cavity 112 for accommodating rotating pressure-applying components. Each of the two through-holes 111 A flexible pipe 20 for transporting liquid is pierced, and a rotating pressure applying assembly 30 is respectively arranged in the two cavities 112. 30 can be rotated with a phase difference of 180 degrees under manpower or electric drive, respectively crushing or loosening the flexible pipe, thereby closing and opening the liquid channel.

[0033] like Figure 9 As shown, the valve body 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com