Combustor capable of quickly realizing flameless combustion

A flameless combustion and burner technology, which is applied to gas fuel burners, burners, combustion types, etc., can solve the problems of scouring furnace walls, furnace erosion damage, lack of flame stabilizing devices, etc., to achieve stable and easy combustion process. The effect of maintenance and quick switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

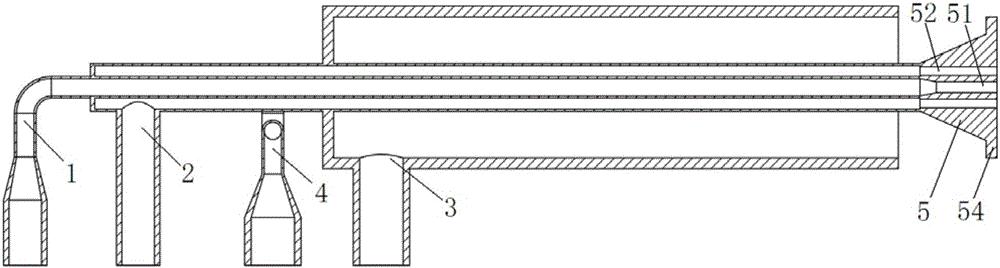

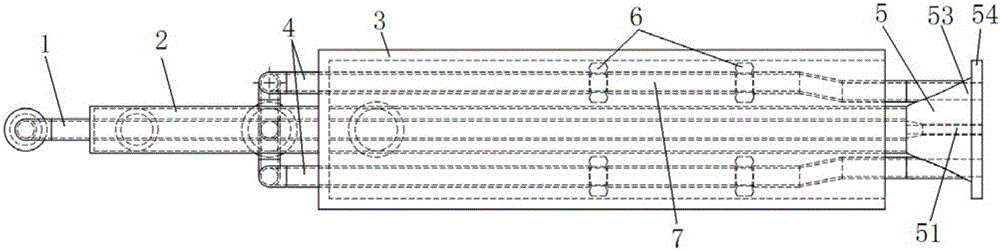

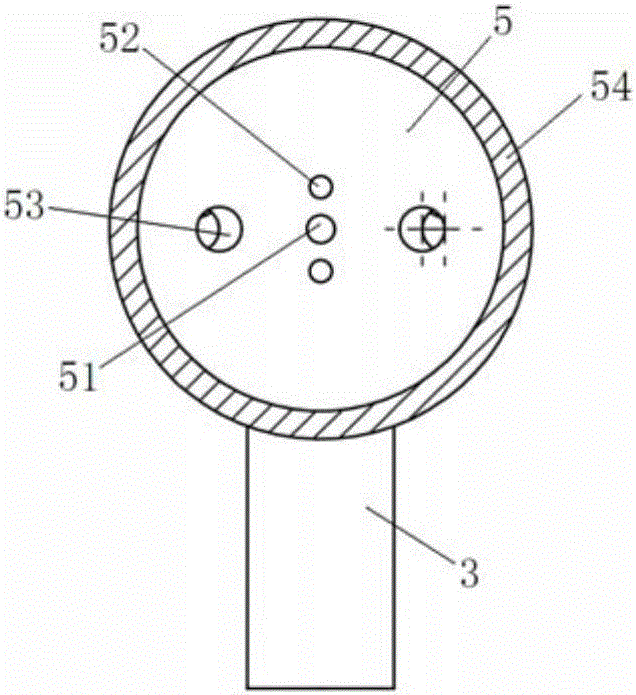

[0017] Such as Figure 1~3 As shown, the present invention includes a central gas nozzle 1, a loop gas nozzle 2 is arranged coaxially outside the center gas nozzle 1, and a loop air nozzle is coaxially arranged outside the loop gas nozzle 2. Pipe 3, two symmetrical air nozzles 4 are arranged parallel and symmetrically on both sides of the loop gas nozzle 2, and the two symmetrical air nozzles 4 are located between the inner wall of the loop air nozzle 3 and the outer wall of the loop gas nozzle 2. The front ends of the central gas nozzle 1 and the loop gas nozzle 2 are jointly connected with a flame-stabilizing blunt body 5, and the flame-stabilizing blunt body 5 is connected with the central gas nozzle 1 and the loop gas nozzle 2 in a detachable manner, such as threaded connection, snap connection, etc. A central gas nozzle 51, more than two periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com