A phase-change heat storage system for residual heat from a ignition stove

A heat storage system and phase-change heat storage technology, applied in air-conditioning systems, heat storage heaters, household stoves, etc., can solve the problems of deterioration of indoor air quality and impact on human health, and achieve significant practicability and popularization. Compact structure and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

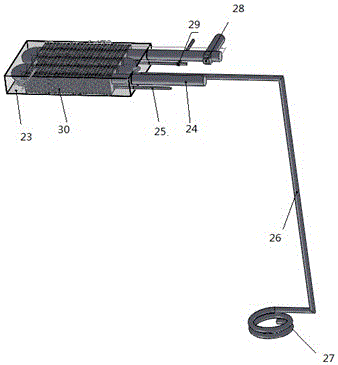

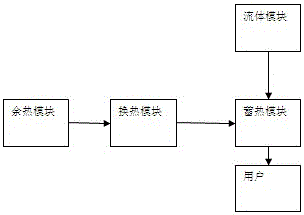

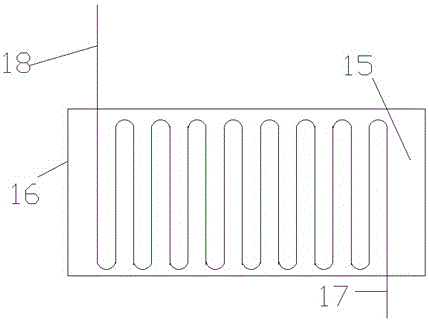

[0037] Such as figure 1 As shown, an ignition stove heat storage system includes a waste heat module 27, a heat exchange module 26, a heat storage module 23, and a fluid module. Module 23, the fluid module includes fluid channels, such as the air inlet channel 24 and the water inlet channel 25 in Embodiment 1, the fluid channels 24, 25 exchange heat with the heat storage system, and transfer heat to the fluid in the fluid channel.

[0038] Preferably, the waste heat module includes a waste heat recovery heat coil with an inner cavity arranged at the combustion port of the stove body.

[0039] Preferably, the heat exchange module 26 is a metal heat pipe, preferably a heat pipe.

[0040] Preferably, the heat storage module 23 is a phase change energy storage box.

[0041] The metal heat pipe is connected to the waste heat module of the ignition stove and the phase chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com