Heating furnace structure

A heating furnace and heating element technology, used in electric furnace heating, lighting and heating equipment, furnaces, etc., can solve the problems of long cooling time and restrict productivity, save time, improve production efficiency, and quickly repair and replace the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

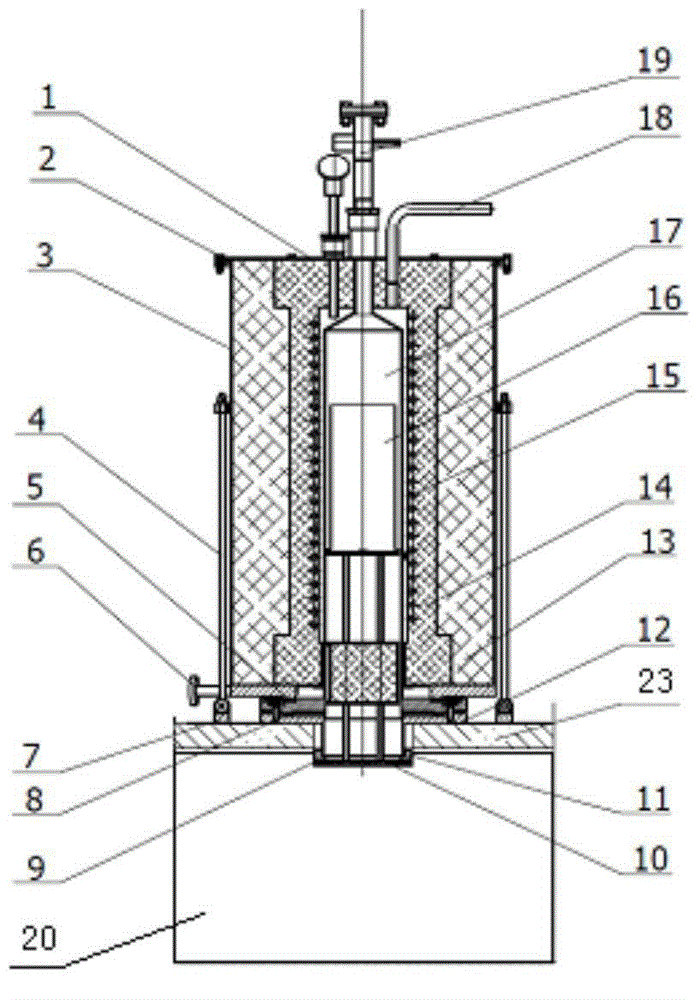

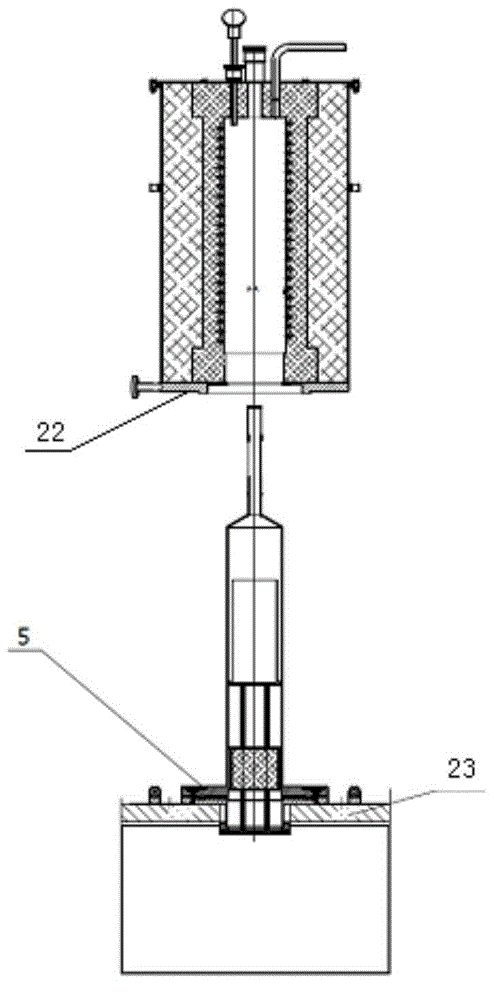

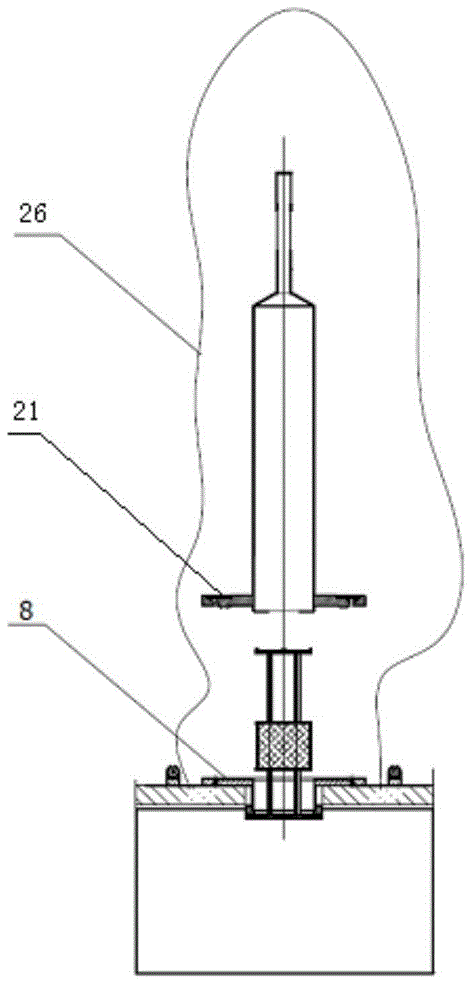

[0020] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-4 As shown, the heating furnace structure provided by the present invention includes a furnace cover 1, a furnace cover sealing ring 2, a furnace shell 3, a locking mechanism 4, a furnace body gasket 5, a furnace inlet pipe 6, a locking fixing member 7, and a furnace Bilder sealing ring 8, furnace mouth sealing ring 9, furnace base 10, furnace mouth flange 11, furnace door flange 12, flexible insulation layer 13, rigid insulation layer 14, heating element 15, material container 16, furnace bladder 17, furnace row The air pipe 18, the furnace tube adapter 19, the chamber 20, the furnace flange 21, the furnace shell flange 22, the heating furnace installation platform 23, the insulation material 24, the bottom plate 25, and the bag seal 26.

[0022] Among them: the furnace cover 1 is a plate-shaped structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com