Honeycomb-shaped disc-shaped vibrating gyro

A vibrating gyroscope, honeycomb-like technology, applied in the direction of speed measurement, gyroscope/steering sensing equipment, measuring device, etc. with gyro effect, can solve the problems of volume, power consumption, and price that are difficult to meet the requirements, and increase the detection capacitance area. , good immunity, good robustness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

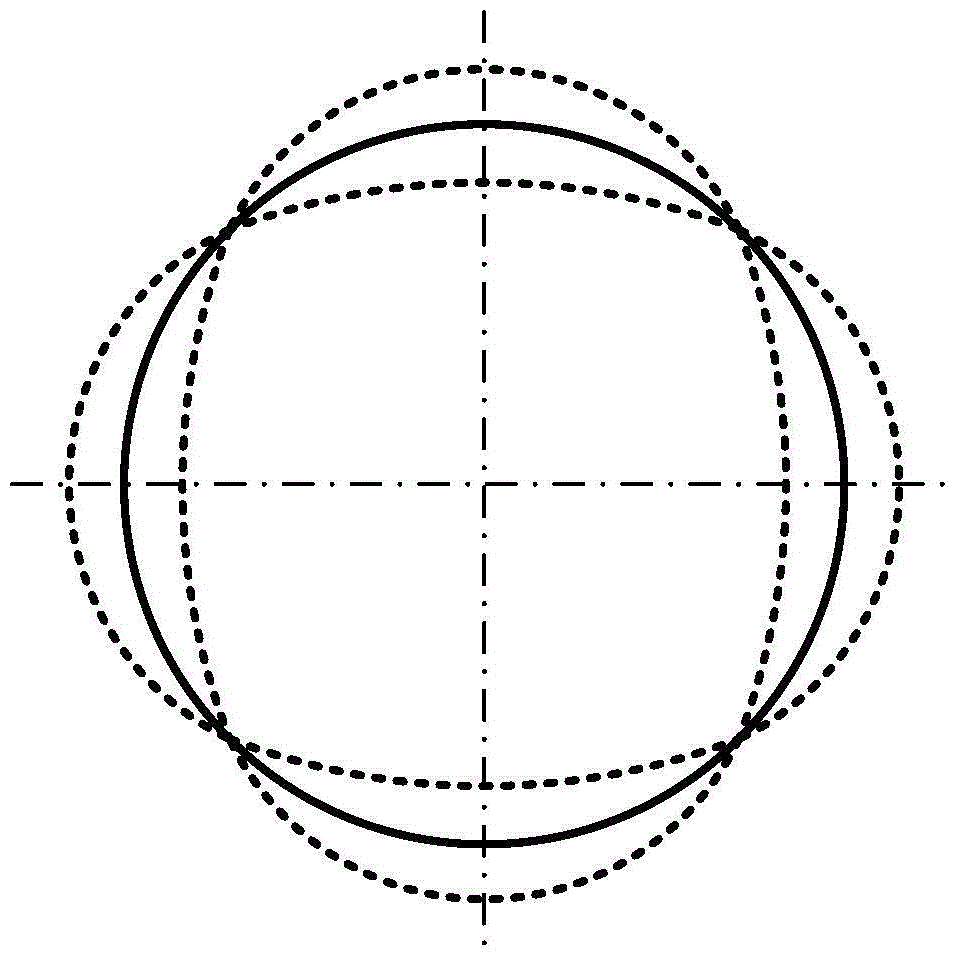

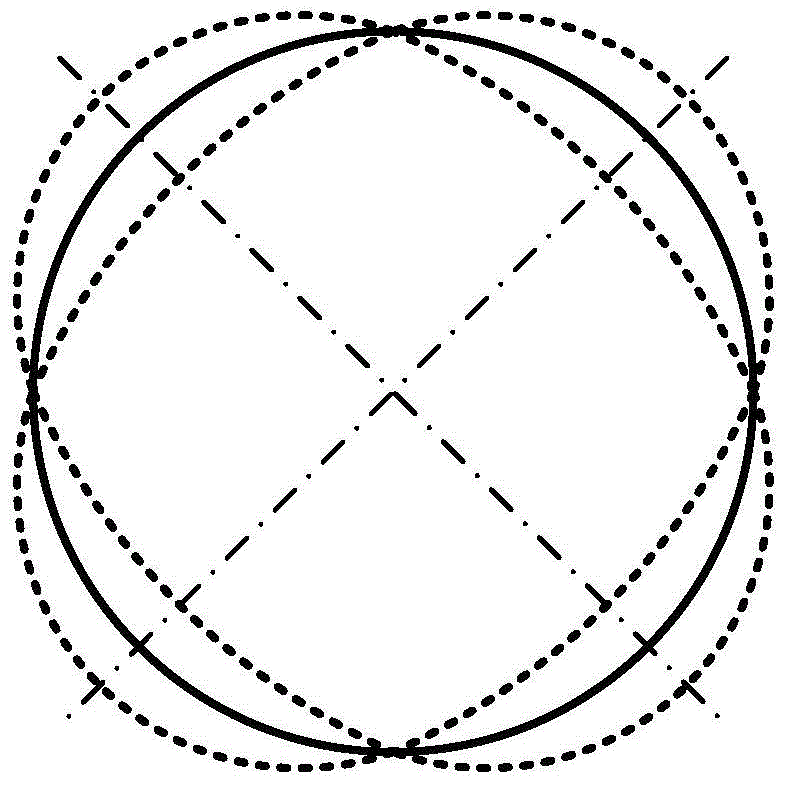

[0041] The working principle of the honeycomb-shaped disc-shaped vibrating gyroscope is as follows: through the electrostatic force driving mode, the harmonic oscillator is excited such as Figure 5A In the driving mode shown, when there is an axial angular velocity input, the harmonic oscillator is generated by the Coriolis force as follows: Figure 5B In the detection mode shown, the vibration of the harmonic oscillator detection mode is converted into a sensitive electrical signal through capacitance detection. The sensitive electrical signal is proportional to the input angular velocity, and the input angular velocity information can be obtained after filtering and amplification.

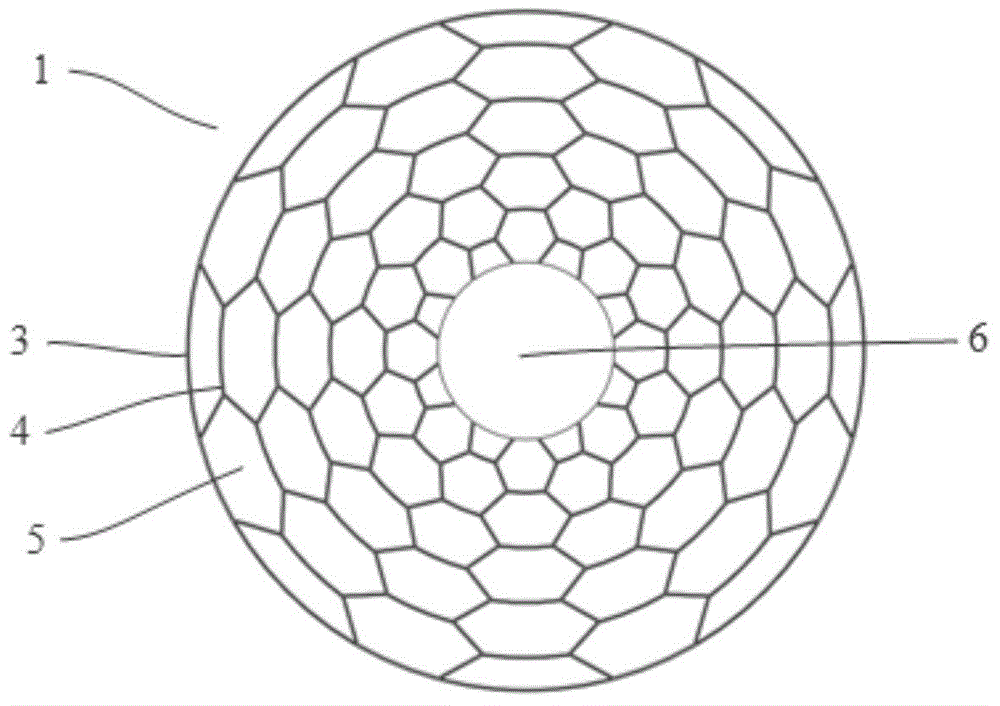

[0042] The arrangement of the electrodes has an important influence on the performance of the honeycomb disc vibrating gyroscope. exist Figure 6A In the shown embodiment, the honeycomb disc-shaped vibrating gyroscope is designed with external electrodes, and the external electrodes 9 are distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com