An up-frequency vibration energy collection system and collection method

A vibration energy harvesting, up-frequency technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. The magnet occupies a large area and the power output is low, so as to achieve the effect of low structural rigidity, large resonance mass and sensitive induction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

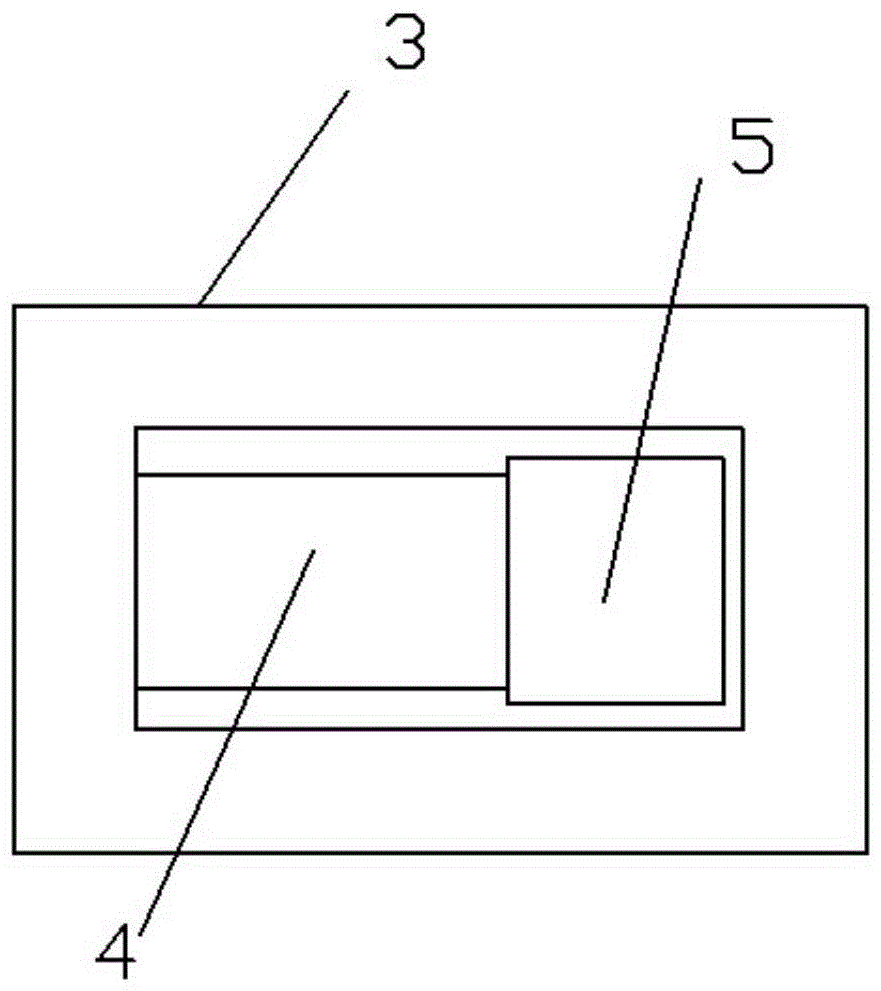

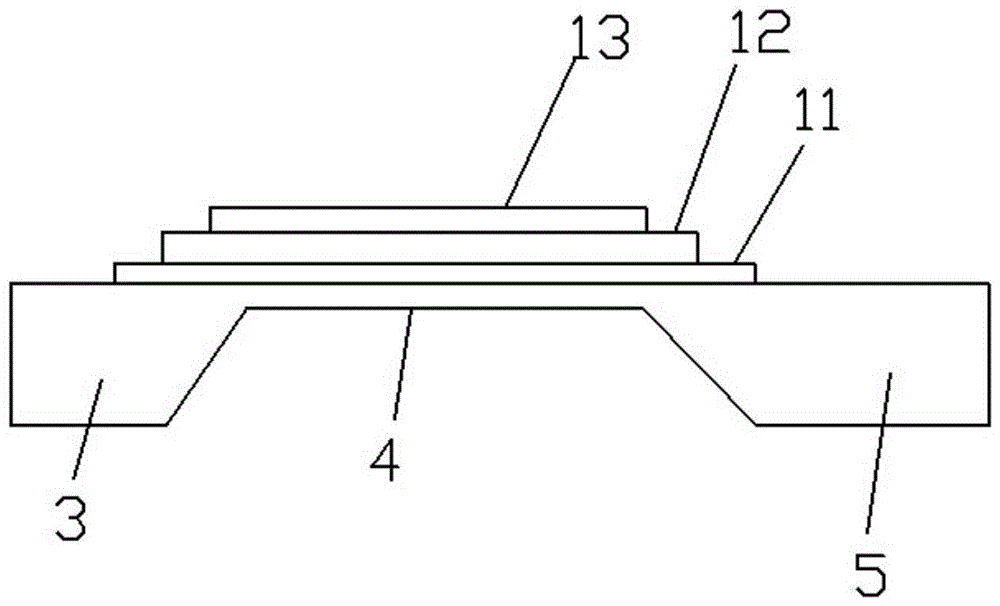

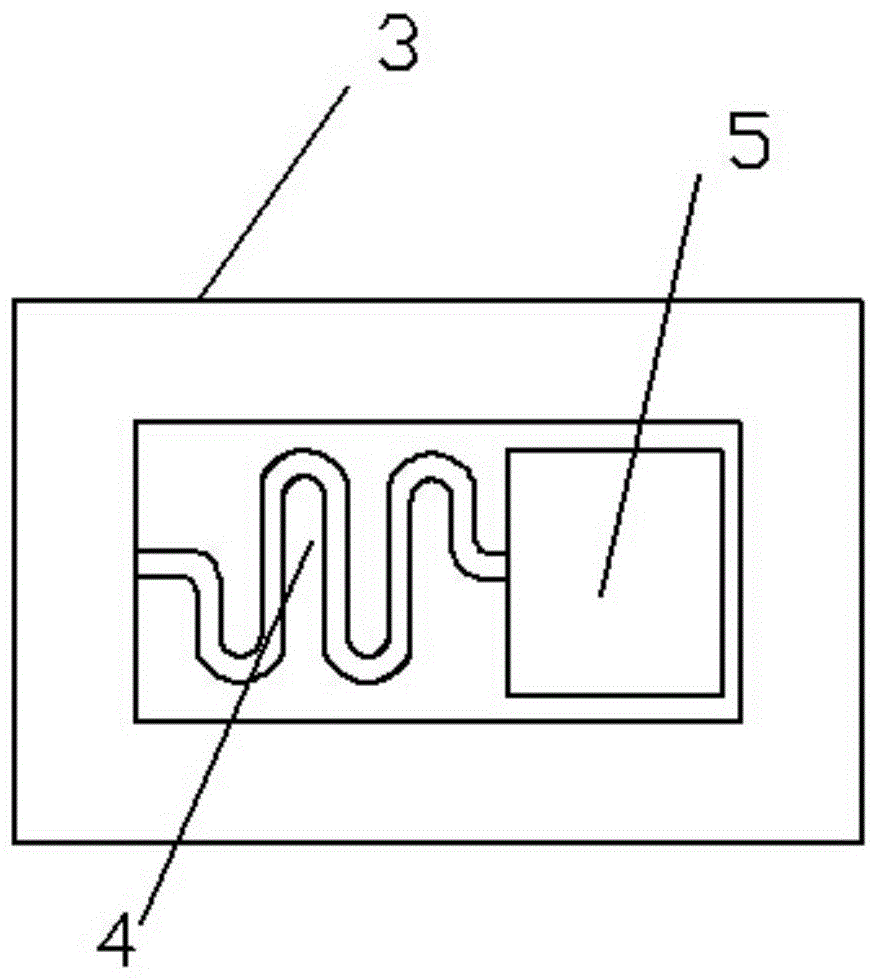

[0051] In the previous work, the experimental work was done on the piezoelectric energy harvesting system based on the collision up-frequency mechanism, and the low-frequency and high-frequency piezoelectric microstructure beams were prepared through the MEMS silicon-based process. The dimensions of the high and low frequency resonant beam chips in the experiment are both 5.2mm*4.2mm*0.4mm. The low-frequency vibration beam adopts a double S-shaped design to reduce the resonance frequency to 20Hz. The resonant frequency of the high-frequency vibration beam is 127Hz, and the surface is coated with a piezoelectric film layer, which can convert mechanical energy into electrical energy output through the piezoelectric effect. Figure 8 It is the test result of the voltage output waveform diagram of the high and low frequency resonant structure. It can be seen from the figure that the voltage output of the high frequency resonant beam (127Hz) is much higher than that of the low freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com