Nested annular MEMS oscillation gyro with period distribution type concentrated mass blocks

A technology of concentrated mass and periodic distribution, applied in the direction of speed measurement, gyroscope/steering induction equipment, measurement device, etc., with gyro effect, can solve the problem of limiting performance of driving amplitude, and achieve large resonance mass, small structural stiffness, large Effect of Drive Amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

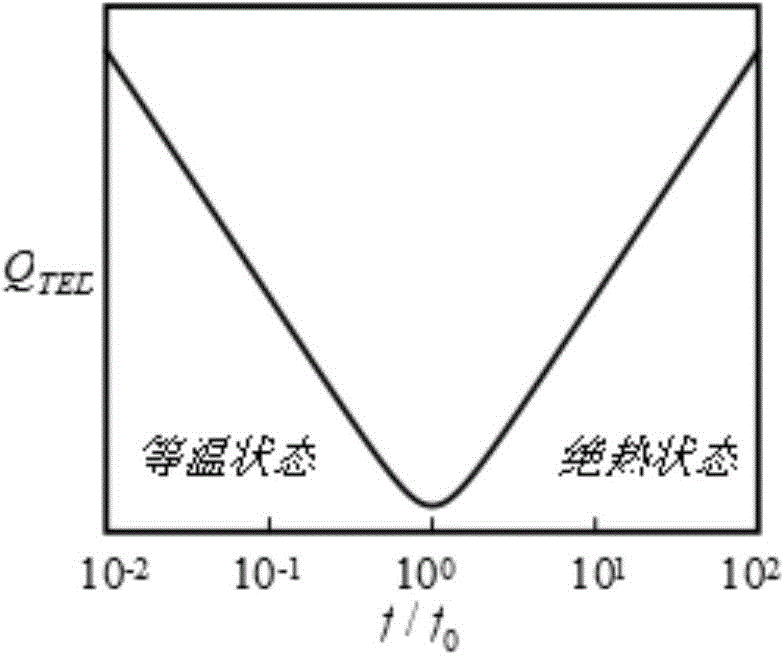

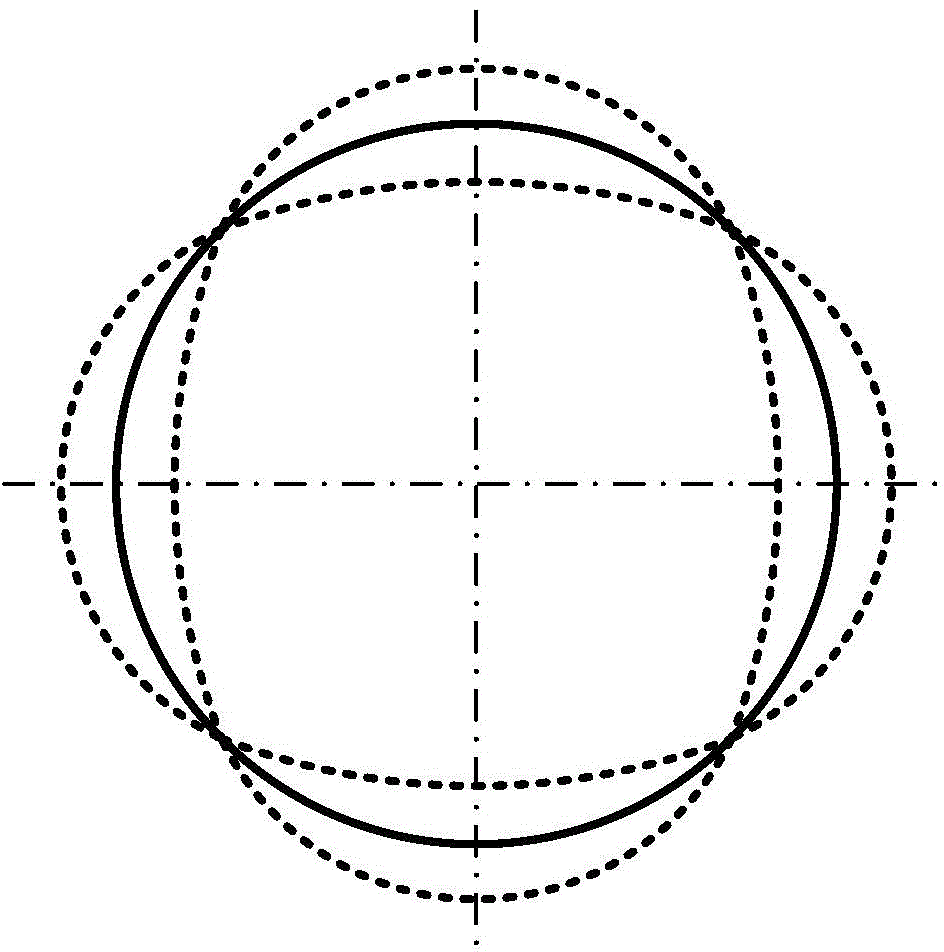

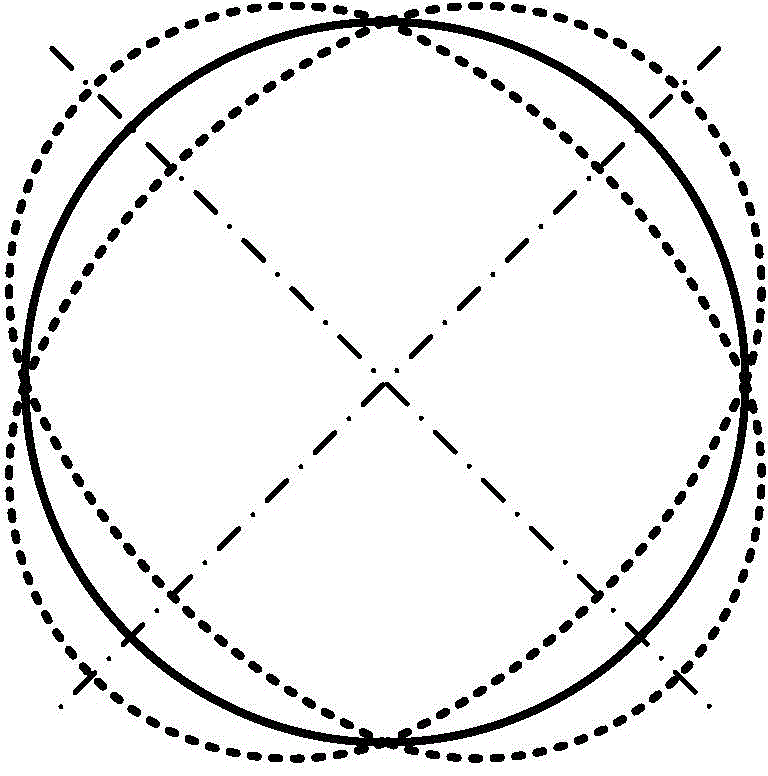

[0050] The invention realizes the decoupling of mass and stiffness by adding lumped masses on the axisymmetric nested ring flexible frame, that is, increasing the resonance mass will not affect or only slightly affect the stiffness of the structure. Such as Figure 3A , 3B , 3C, and 3D show the topological schematic diagram (left figure) and structural schematic diagram (right figure) of the four embodiments of the harmonic oscillator with lumped mass added to the nested ring flexible frame. In the embodiment, the nested ring flexible frame 1 Consisting of nesting rings 2 and spoke-shaped support beams 3, the entire structure is firmly anchored to the base through anchor points 4.

[0051] Figure 3A In the shown embodiment, the mass blocks 5 are arranged on the spoke-shaped support beams 3 of the nested ring flexible frame 1, and the distance between adjacent nested rings 2 is equal and a ring is formed between adjacent nested rings 2, which are relatively The adjacent nes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com