Method and device for relatively locating coal cutter and hydraulic supports

A technology of hydraulic support and positioning device, which is applied in directions such as navigation through speed/acceleration measurement, and can solve problems such as cumulative errors, low reliability and accuracy of shearer positioning, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing.

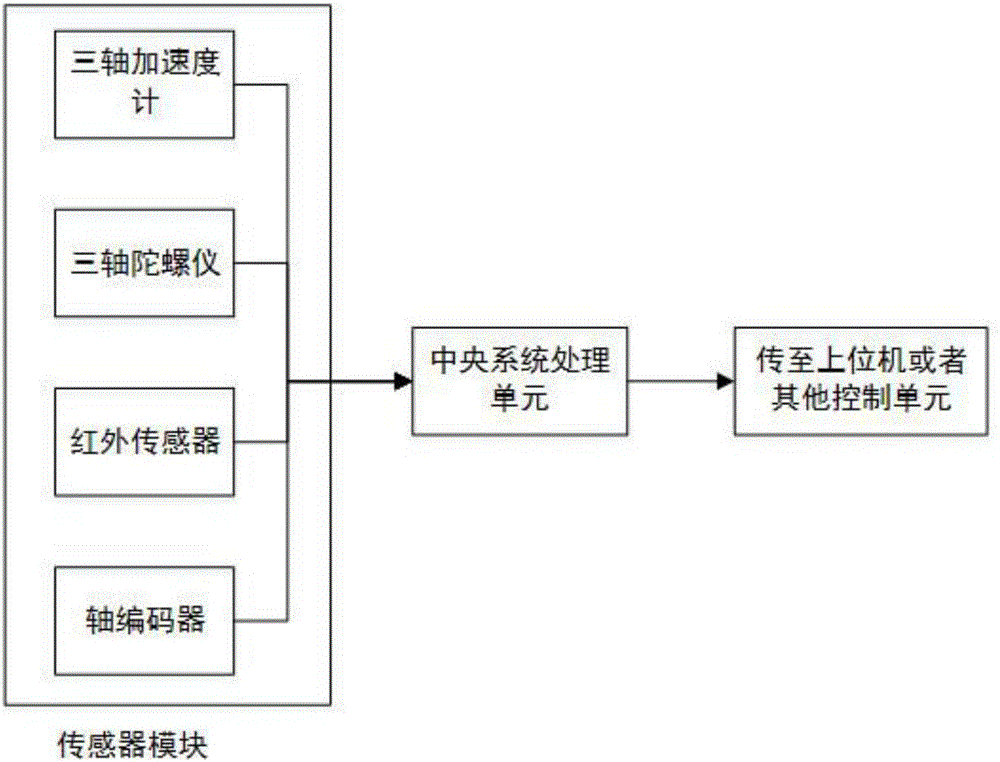

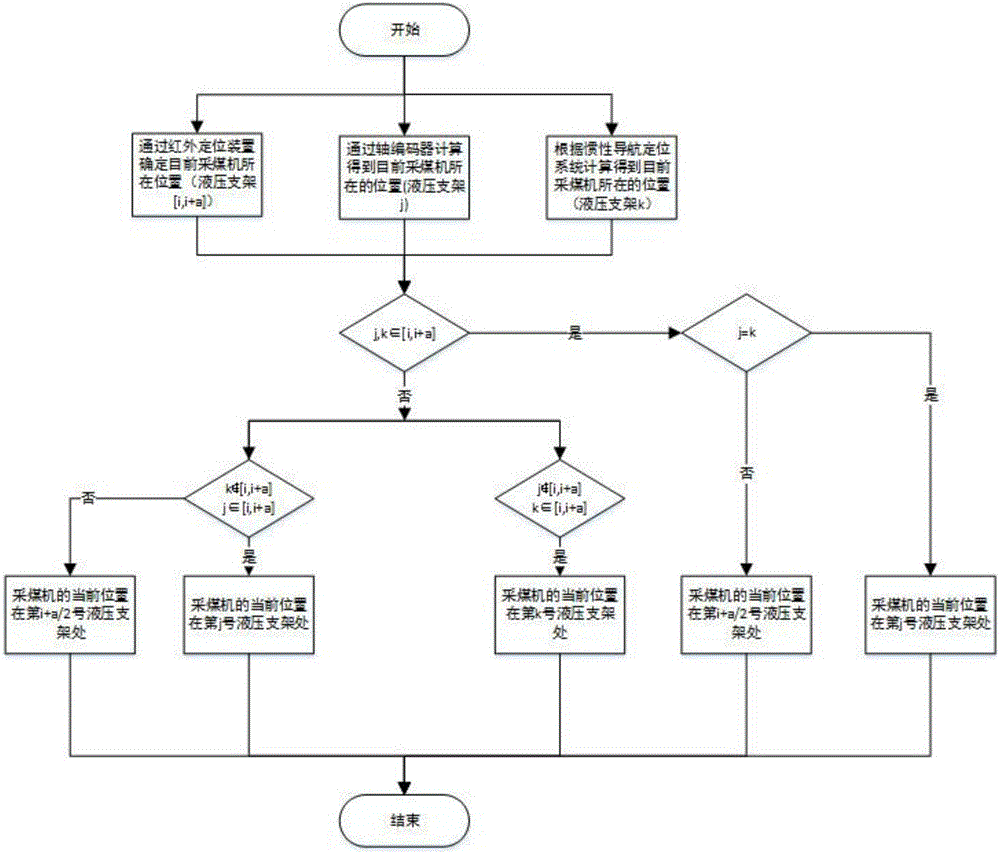

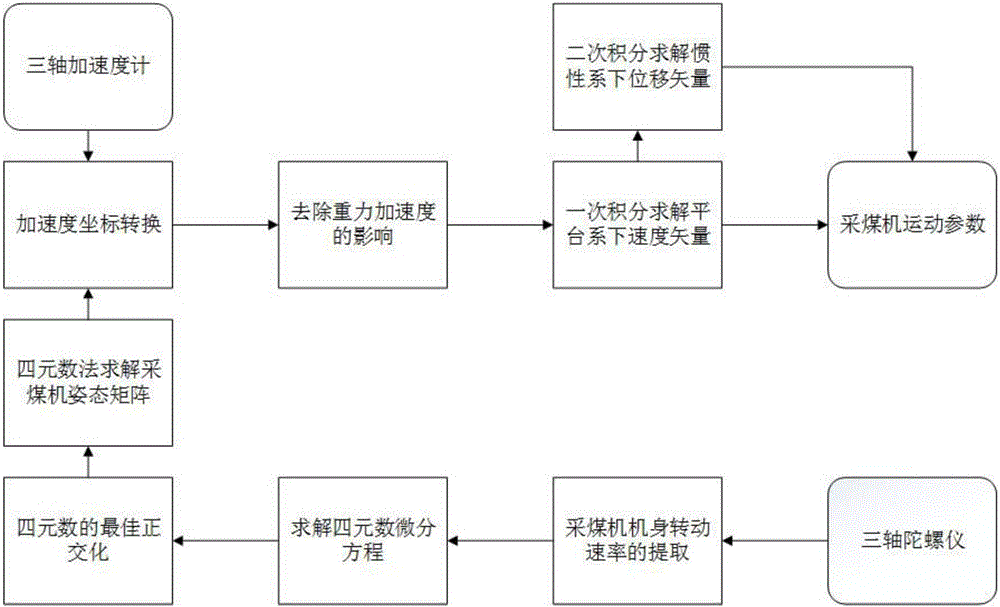

[0058] Such as Figure 1 to Figure 3 Shown: the coal shearer-hydraulic support relative positioning device of the present invention includes an infrared sensor, a shaft coding positioning device, an inertial navigation positioning device and a central system processing unit, and the inertial navigation positioning device, the shaft coding positioning device and the infrared sensor are respectively electrically connected It is located in the central system processing unit; the inertial navigation positioning device is installed at the center of gravity of the shearer, the shaft encoding positioning device is placed on the low-speed output shaft of the planetary reducer in the traveling part of the shearer, and the infrared sensor includes a sensor installed at the center of the shearer. An infrared emitting device and a plurality of infrared receiving devices installed on ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com